Direct smelting process

A direct, metal smelting technology, applied in the field based on molten baths, can solve problems such as difficult mixing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The following description is for the production of molten iron according to the HIsmelt process in the case of smelting a metal charge in the form of iron ore fines (typically less than 6 mm). However, it should be understood that the invention is not limited to iron ore and can be applied to smelting any metal material in any material form. Ore is an example of a form of metal material. The invention also extends to other forms of metal material, including by way of example partially reduced ores and metal-bearing waste streams.

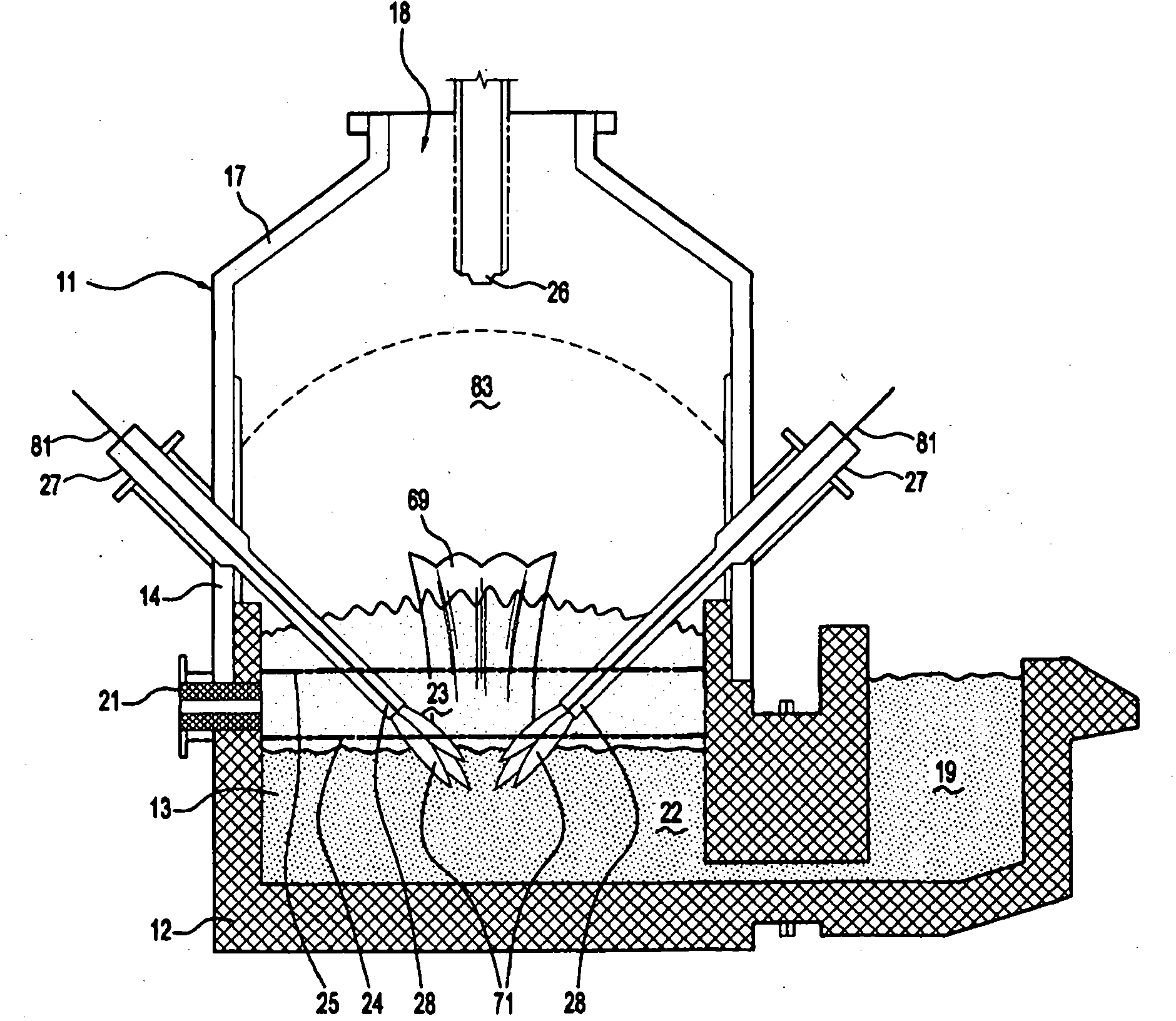

[0069] Referring to the drawings, there is shown a vessel 11 having a hearth for containing a molten bath of iron and slag, the hearth comprising a base 12 formed of refractory bricks and sides 13, side walls 14 (which are formed from The sides 13 of the hearth are upwardly extending generally cylindrical barrels) and the top 17 . The side walls 14 and top 17 include water cooling plates (not shown) for transferring heat from the side walls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com