Rapid nondestructive detection apparatus of vacuum degrees of containers, and detection method thereof

A container vacuum and non-destructive testing technology, applied in vacuum gauges, instruments, measuring devices, etc., can solve the problems of slow detection speed, container vacuum detection can not meet productivity, large economic losses, etc., to achieve the effect of non-destructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following will further describe the embodiments of the present invention in detail with reference to the accompanying drawings:

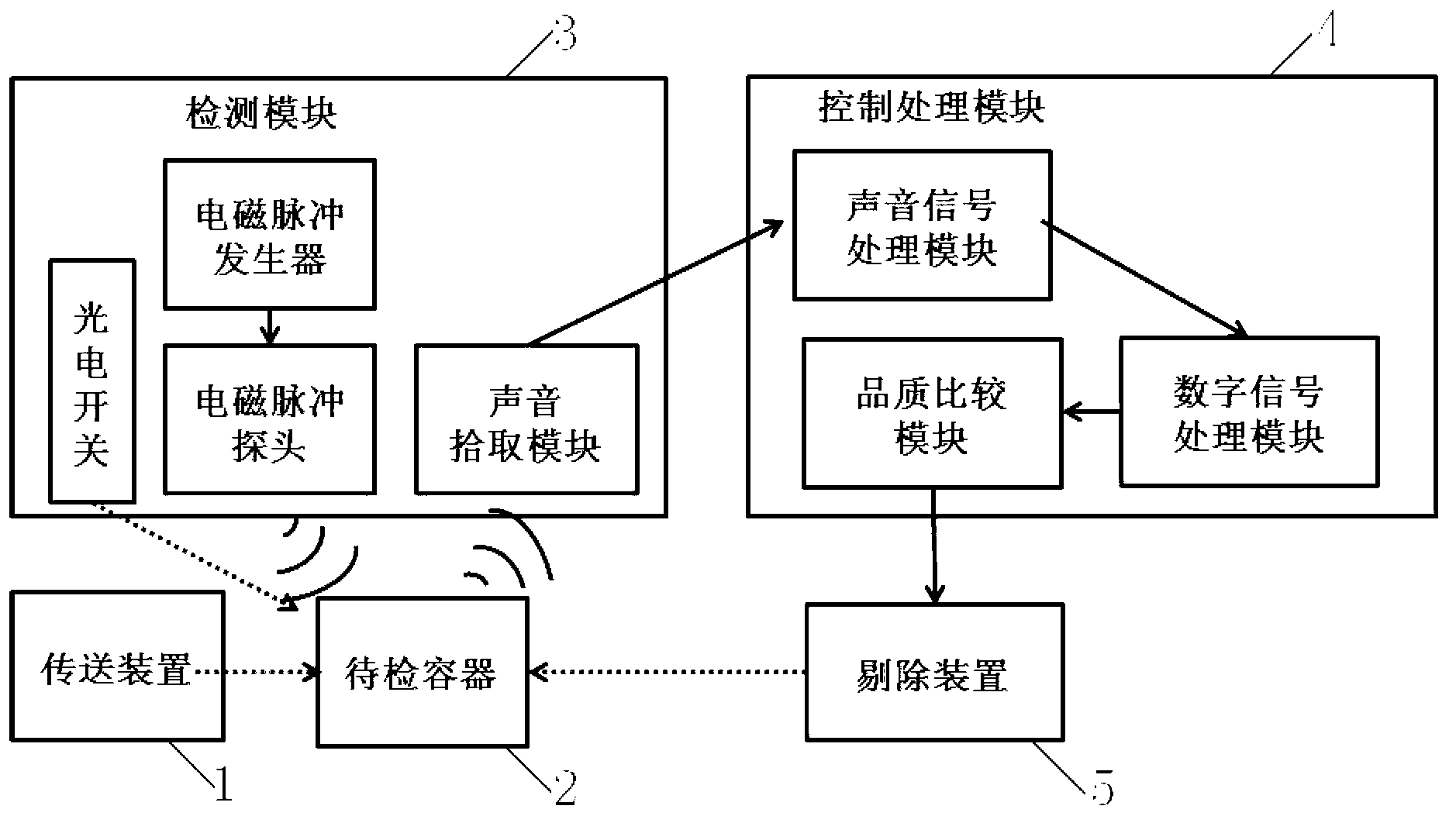

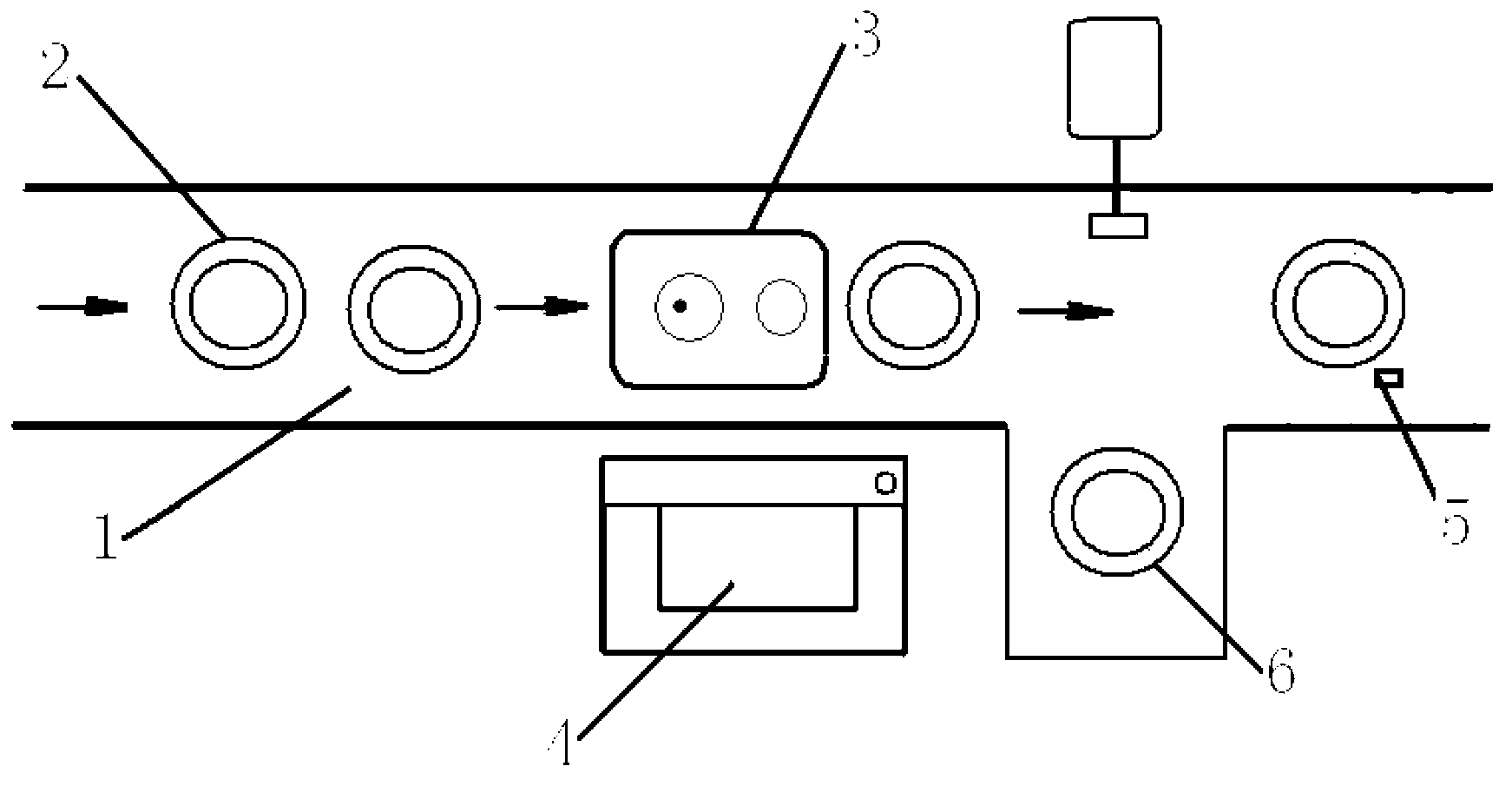

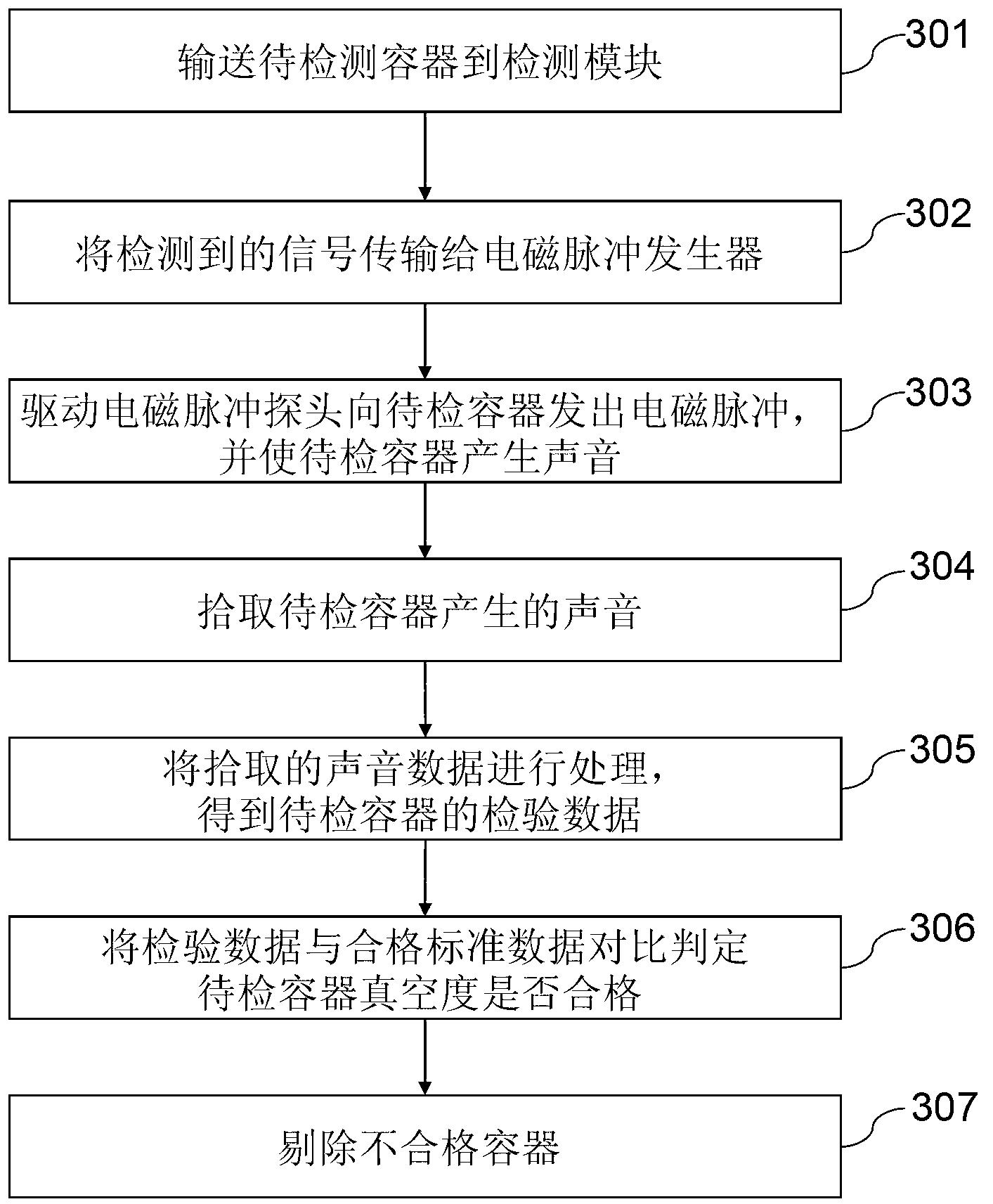

[0034] See figure 1 with figure 2 , Is the structure of the equipment for rapid non-destructive testing of container vacuum and the structure of the equipment on the production line. The equipment includes: a conveying device 1, a detection module 3, a control processing module 4, and a rejection device 5; the conveying device is used for conveying The container to be inspected 2; the detection module is used to make the container to be inspected emit electromagnetic pulse signals and pick up the sound generated by the electromagnetic pulse signal; the control processing module is used to process sound data to obtain inspection data of the container to be inspected, The inspection data is compared with the qualified standard data to determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com