Multi-functional drilling-riveting actuator

An actuator, multi-functional technology, applied in other manufacturing equipment/tools, metal processing mechanical parts, precision positioning equipment, etc., can solve the problems of single function and low efficiency of equipment, achieve strong versatility and improve the efficiency of drilling and riveting work , The effect of reducing the number of replacement work heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] This embodiment is a multifunctional drilling and riveting actuator.

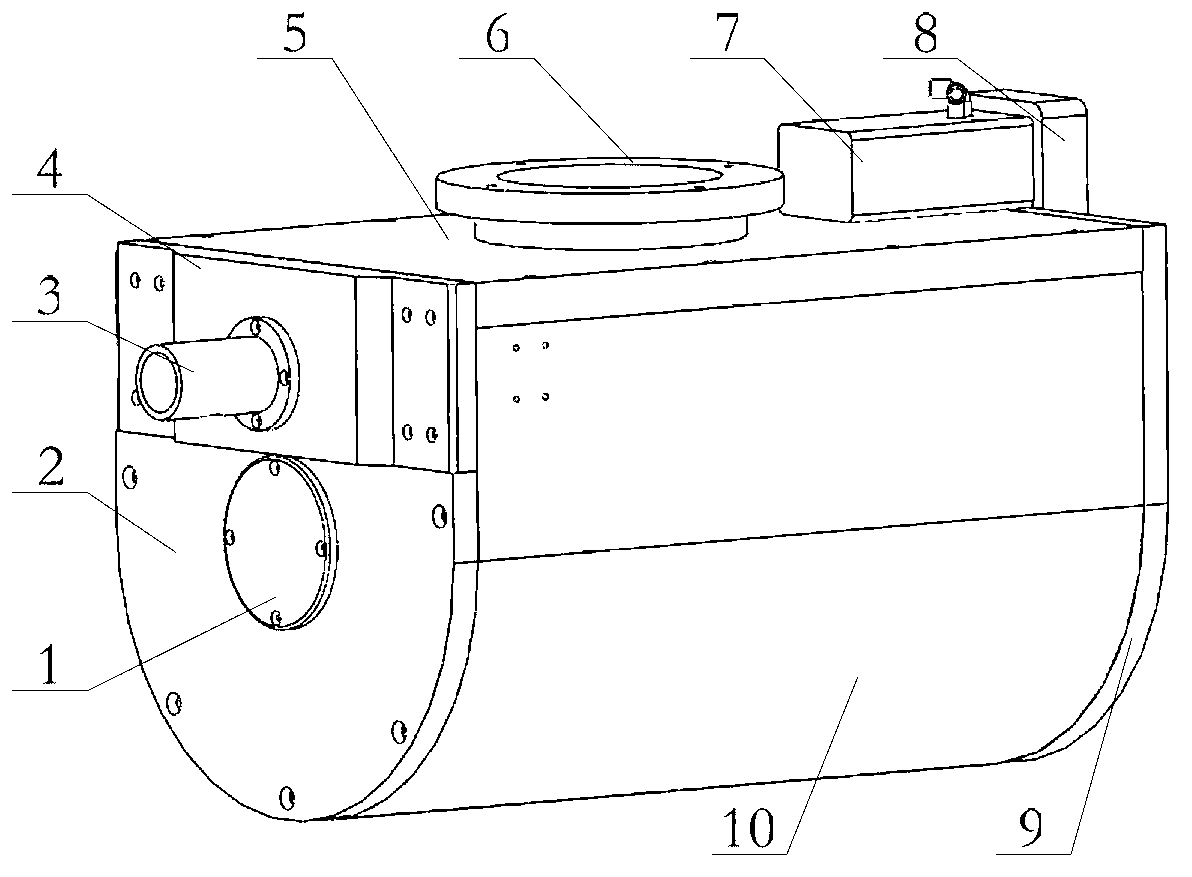

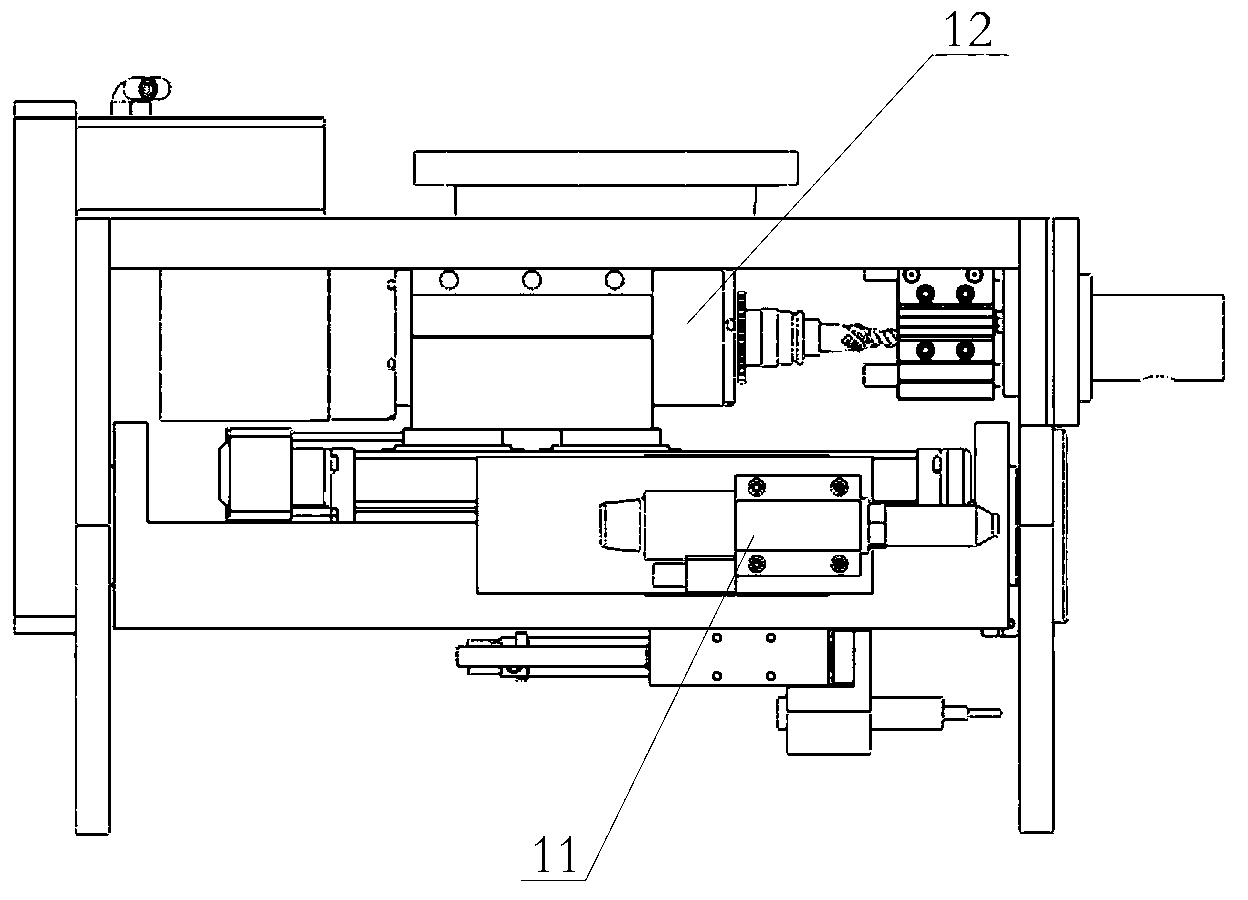

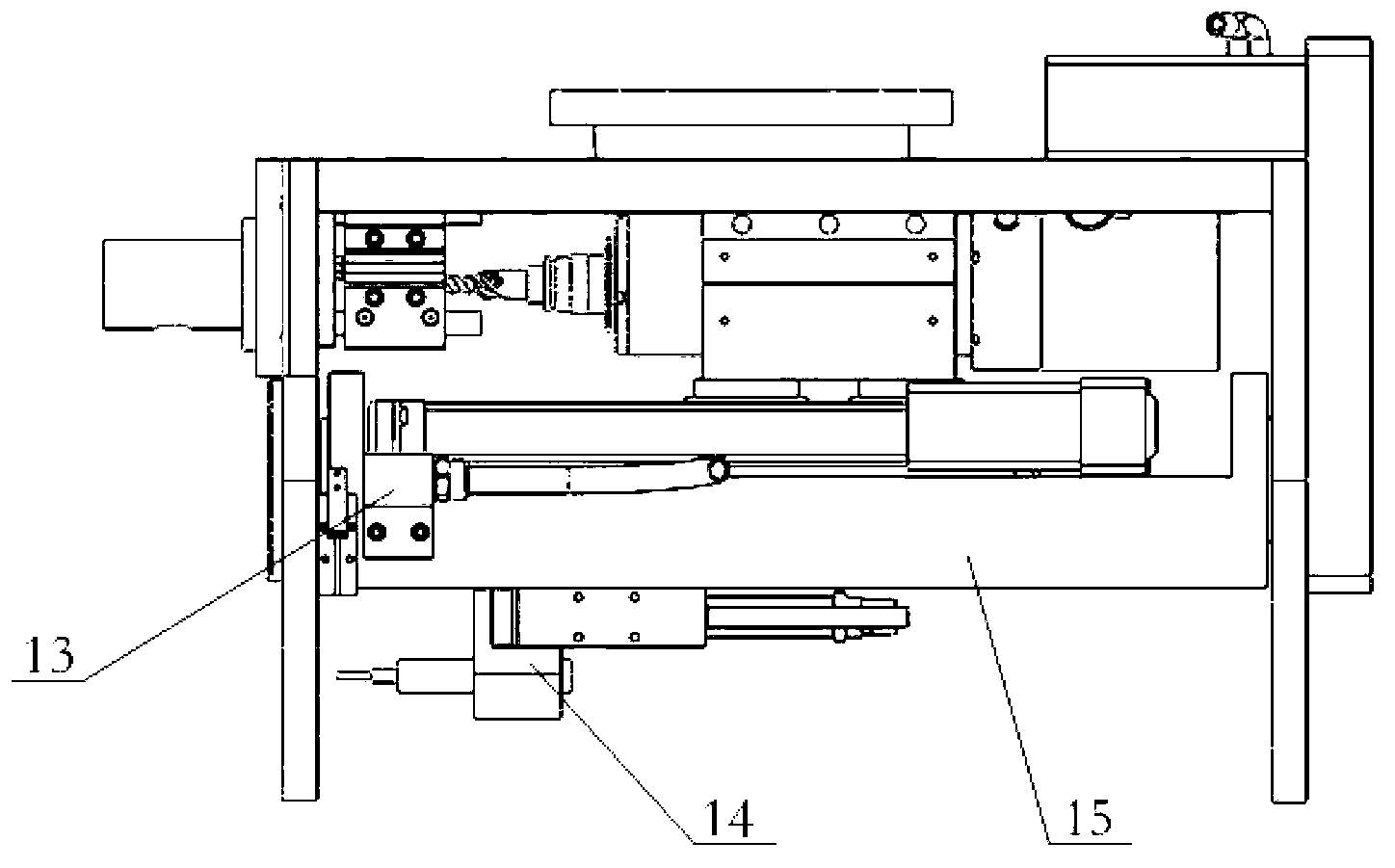

[0028] refer to figure 1 , figure 2 , image 3 , The drilling and riveting actuator includes a housing, a pressing mechanism, an indexing mechanism, a drilling mechanism, a glue coating mechanism, a nail feeding mechanism, and a riveting mechanism; the casing includes a front end cover 2, a rear end cover 9, a lower protective cover 10, an upper Cover 5 and connecting flange 6. The indexing mechanism 15 comprises an indexing drive motor 7, an indexing transmission mechanism 8, an indexing turntable 18, a front indexing bearing 19, and a rear indexing bearing 17. The indexing turntable 18 is a rectangular groove body structure, and the two ends are installed The front indexing bearing 19 and the rear indexing bearing 17, the indexing turntable is supported on the front end cover 2 and the rear end cover 9 in the housing through the front indexing bearing 19 and the rear indexing bearing 17, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com