Automatic distribution method for tire warehouse-entering channels

An automatic distribution and automatic sorting system technology, applied in the direction of transportation, packaging, storage devices, etc., can solve the problems of low production efficiency, high labor intensity of operators, and high labor intensity, so as to improve production efficiency and save sorting area , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

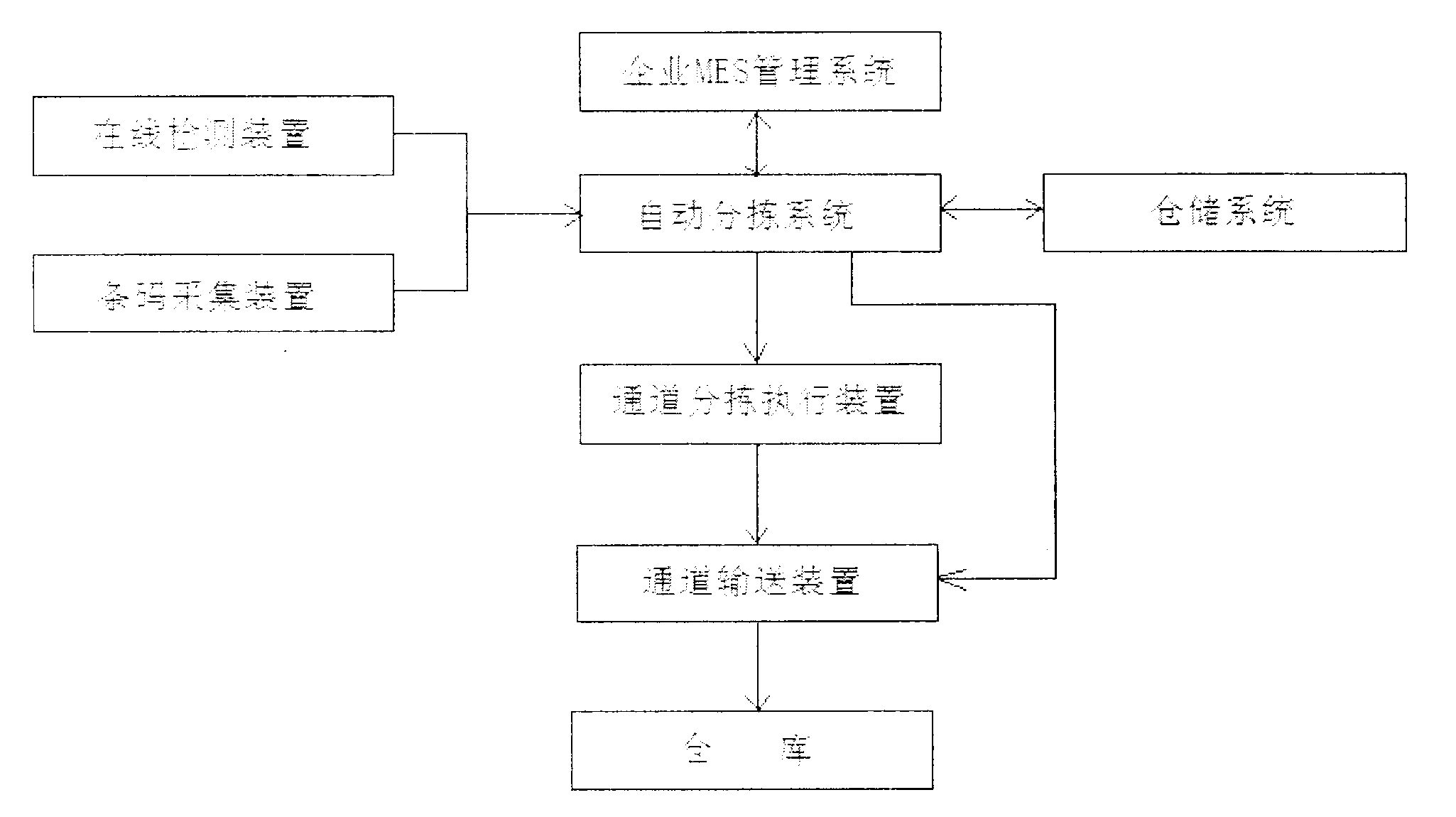

[0009] Such as figure 1 The shown automatic distribution method for storage channels, the method includes: Step 1, the barcode collection device and the online detection device collect and online detect the tire specification information, and transfer the collected information to the automatic sorting system; Step 2, automatically The sorting system compares the tire specification information transmitted in step 1 with the existing tire specification information in the sorting channel to determine whether the tire specification exists; step 3 and step 2 judge that the information exists, and then the automatic sorting system delivers the specification When the tires arrive at the corresponding sorting channel, the channel sorting execution device executes channel sorting and stacking according to the instructions sent by the automatic sorting system; step 4 and step 2 judge whether the information does not exist, and then judge whether there is an idle channel in the channel; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com