Anti-push road roller

A road roller and frame technology, which is applied in the field of anti-push extrusion road machines, can solve the problems of affecting the compaction effect of the mixture, contact area, and insufficient action time, and achieve the effects of easy promotion and use, simple structure, and guaranteed flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

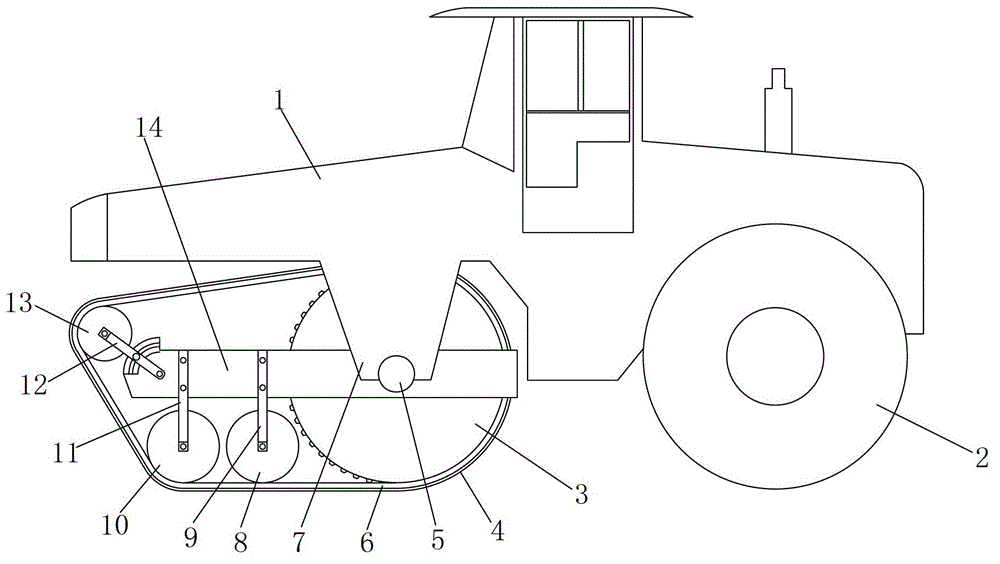

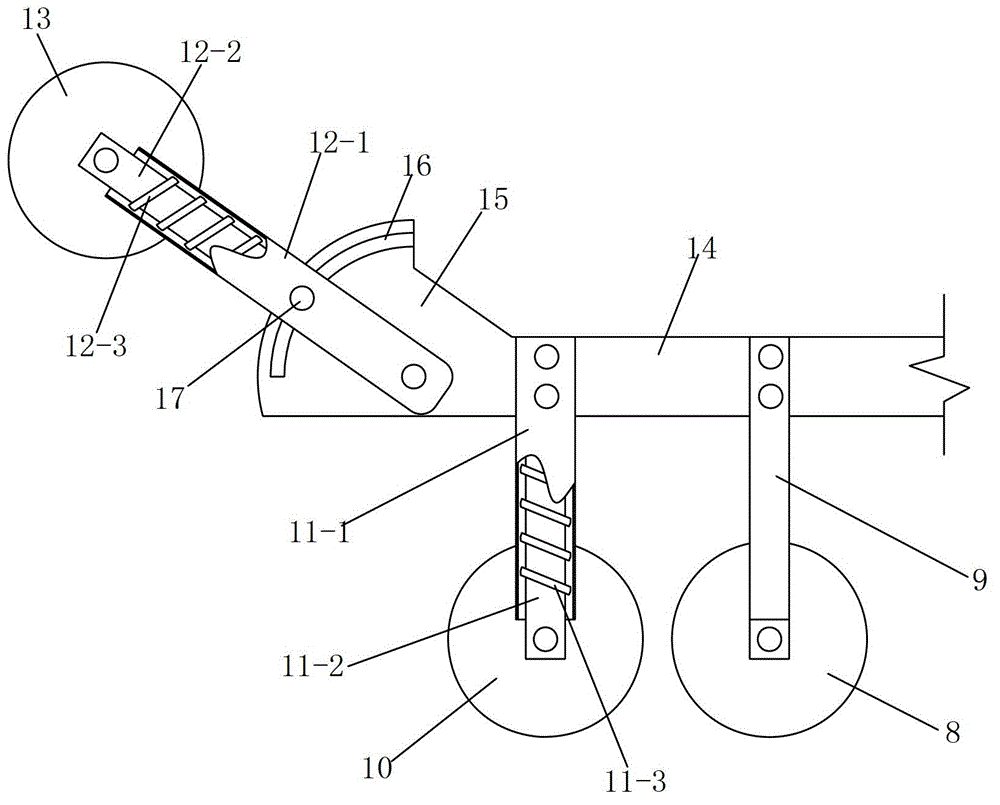

[0030] Such as figure 1 and figure 2 The shown anti-push extrusion road machine includes a frame 1 and a main compacting wheel 3 rotatably connected to the frame 1. Both sides of the main compacting wheel 3 are provided with connecting plates 14, and the main compacting wheel 3 The front of the solid wheel 3 is provided with an initial compaction wheel 10, and both sides of the initial compaction wheel 10 are provided with connectors 2 11, and the connectors 2 11 on both sides of the initial compaction wheel 10 are connected with the main compaction wheel 3. The connecting plates 14 on both sides are connected one by one. The main compacting wheel 3 is equipped with a crawler belt 6 that is wound on the primary compacting wheel 10 and is used to drive the primary compacting wheel 10 to rotate. The primary compacting wheel 10 A belt adjustment wheel 13 for adjusting the angle between the crawler belt 6 and the contact surface of the asphalt mixture is provided above the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com