Composite panel earth and rockfill dam and anti-seepage body construction method

A composite material and earth-rock dam technology, which is applied in the construction field of composite face earth-rock dam and its anti-seepage body, can solve problems affecting the safety and normal operation of the dam, difficult to coordinate deformation, cracking of reinforced concrete face, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

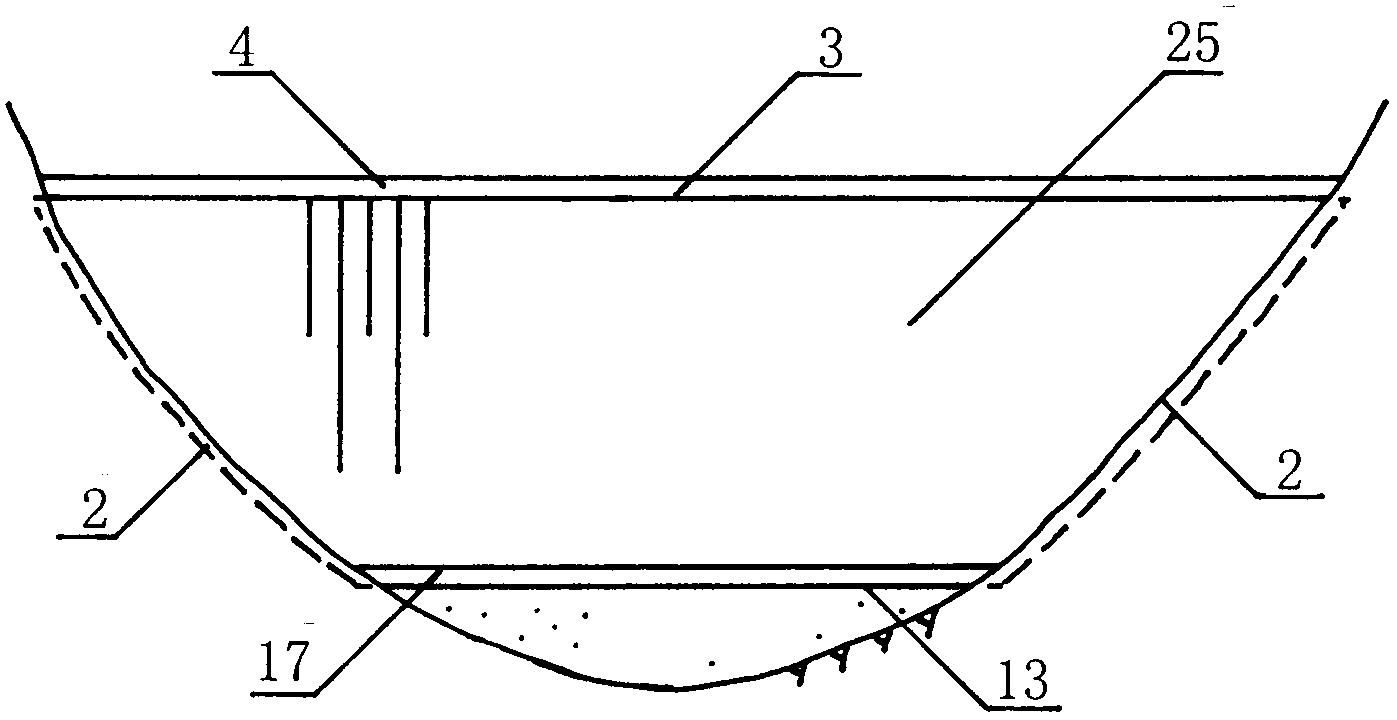

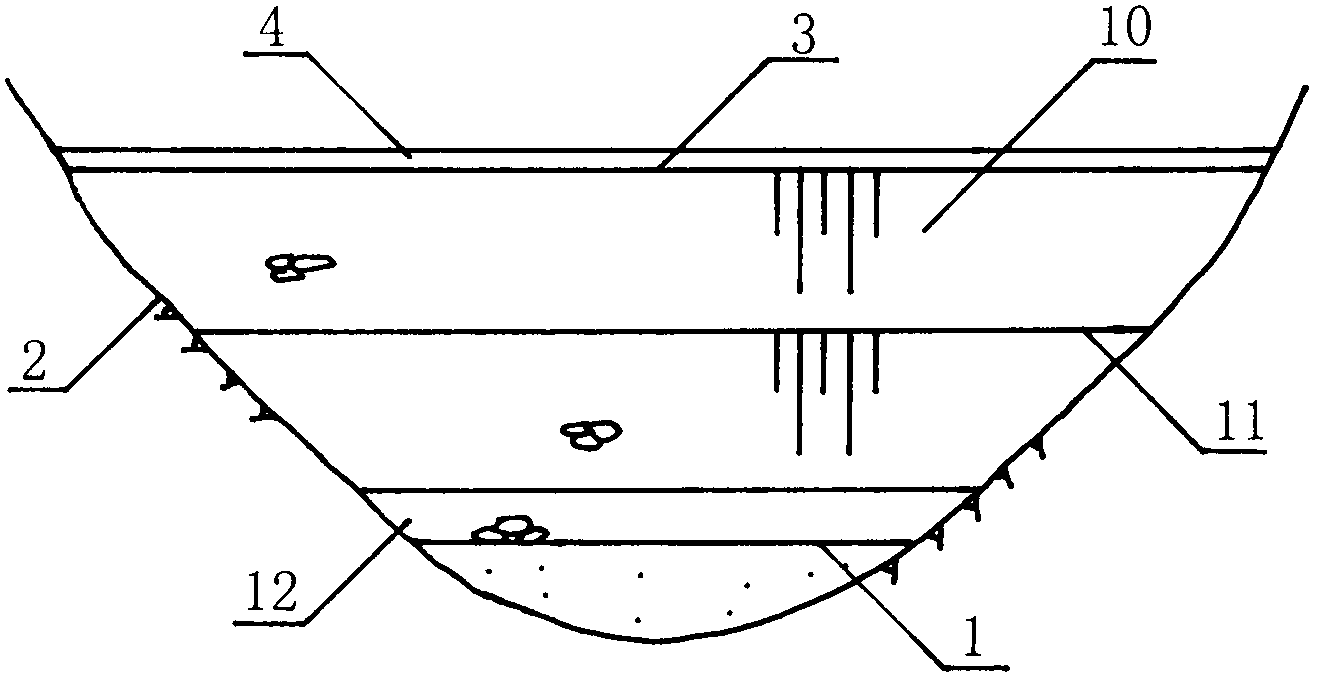

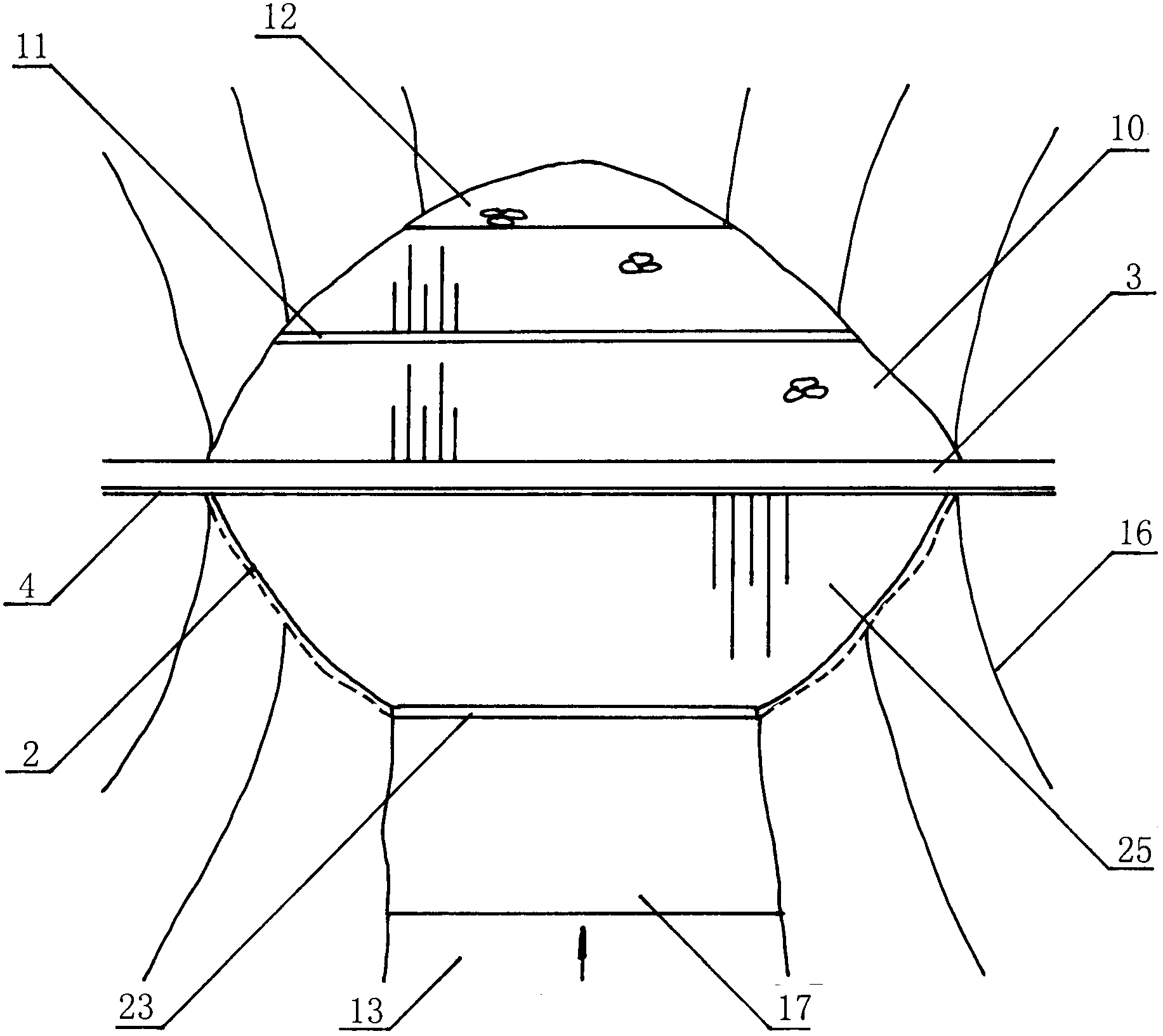

[0031] see figure 1 , figure 2 , image 3 and Figure 4, a composite material face rock dam in the present embodiment includes a sandwich bedding 17, a board seat 23, a composite material face plate 25, a wave wall 4, a transition layer 8, an earth-rock dam body 9, and the cross-section of the earth-rock dam body 9 The surface is trapezoidal, the dam crest 3 has a wave wall 4, and the upstream river bed 13 has a flat sandwich bedding 17, and there is a board seat 23 at the foot of the upstream slope from the dam foundation to the abutments 2 on both sides, and the board seat 23 is under A curtain 5 is provided, and there is a composite material panel 25 on the entire upstream dam slope and in the embedding groove of the abutment 2. There is a transition layer 8 that is thin at the top and thick at the bottom and obliquely placed between the composite panel 25 and the earth-rock dam body 9. There is a block stone slope protection 10 on the slope and a horse path 11 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com