Composite brick for monitoring diversion canal dyke leakage and manufacturing method

A technology of composite bricks and dikes, applied in the field of composite bricks, can solve problems such as easy misjudgment of dikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

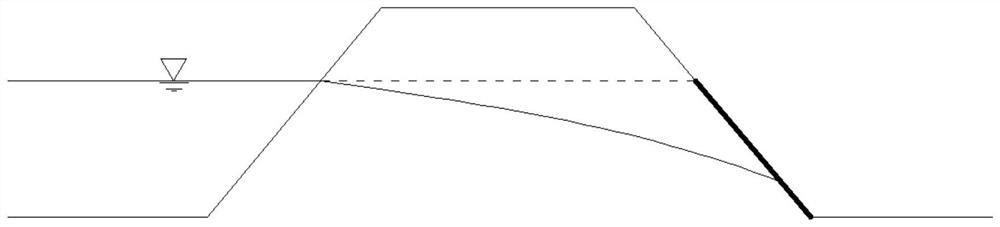

Image

Examples

Embodiment 1

[0021] The length, width and height of the composite brick used to monitor the leakage of the diversion canal embankment are 240mm×120mm×55mm; it includes 7 parts of water, 45 parts of aeolian sand, 10 parts of polypropylene fiber, 10 parts of epoxy resin, 4 parts thinner and 10 parts copper sulfate.

[0022] The manufacturing method of the composite brick used for monitoring the seepage of aqueduct embankment comprises the step (1), mixing 7 parts of water and 45 parts of aeolian sand to obtain aeolian mortar;

[0023] Step (2), adding 10 parts of polypropylene fibers to the aeolian mortar in step (1), stirring for 5 minutes, so that 10 parts of polypropylene fibers are evenly distributed in the aeolian mortar to form fiber-reinforced aeolian sand;

[0024] Step (3), 4 parts of diluents are added in 10 parts of epoxy resins;

[0025] Step (4), adding the epoxy resin after step (3) to the fiber-reinforced aeolian sand in step (2) to obtain a mixed mortar, and stirring for 2 m...

Embodiment 2

[0031] The length, width and height of the composite brick used to monitor the leakage of the diversion canal embankment are 240mm×120mm×55mm; it includes 8 parts of water, 55 parts of aeolian sand, 20 parts of polypropylene fiber, 20 parts of epoxy resin, 6 parts thinner and 20 parts copper sulfate.

[0032] The manufacturing method of the composite brick used for monitoring the seepage of aqueduct embankment comprises the step (1), mixing 8 parts of water and 55 parts of aeolian sand to obtain aeolian mortar;

[0033] Step (2), adding 20 parts of polypropylene fibers to the aeolian mortar in step (1), stirring for 5 minutes, so that 20 parts of polypropylene fibers are evenly distributed in the aeolian mortar to form fiber-reinforced aeolian sand;

[0034] Step (3), 6 parts of diluents are added in 20 parts of epoxy resins;

[0035] Step (4), adding the epoxy resin after step (3) to the fiber-reinforced aeolian sand in step (2) to obtain a mixed mortar, and stirring for 2 m...

Embodiment 3

[0041] The length, width and height of the composite brick used to monitor the leakage of the diversion dike embankment are 240mm×120mm×55mm; it includes 8 parts of water, 50 parts of aeolian sand, 15 parts of polypropylene fiber, 15 parts of epoxy resin, 5 parts thinner and 15 parts copper sulfate.

[0042] The manufacturing method of the composite brick used for monitoring the seepage of aqueduct embankment comprises the step (1), mixing 8 parts of water and 50 parts of aeolian sand to obtain aeolian mortar;

[0043] Step (2), adding 15 parts of polypropylene fibers to the aeolian mortar in step (1), stirring for 5 minutes, so that 15 parts of polypropylene fibers are evenly distributed in the aeolian mortar to form fiber-reinforced aeolian sand;

[0044] Step (3), 4 parts of diluents are added in 15 parts of epoxy resins;

[0045] Step (4), adding the epoxy resin after step (3) to the fiber-reinforced aeolian sand in step (2) to obtain a mixed mortar, and stirring for 2 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com