High-efficiency and high-precision detection device for circular arc roundness of cutter point of diamond cutter

A diamond tool and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to measure the profile of the flank surface, the inability to directly obtain the roundness of the tool tip arc, and the small scanning range. Achieve the effect of overcoming the small measurement range, convenient centering and measurement, and reasonable overall layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

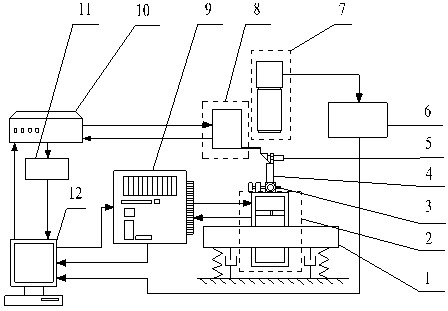

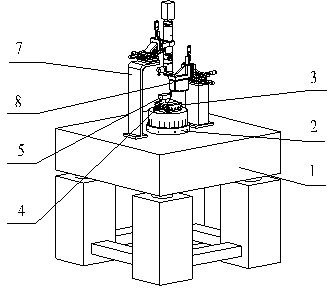

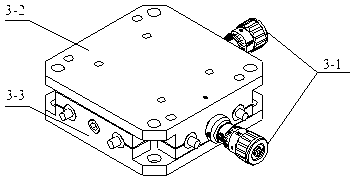

[0023] Such as Figure 1~Figure 6 As shown, the high-efficiency and high-precision detection device for the arc roundness of the diamond tool tip involved in this example includes a vibration isolation platform 1, a precision air bearing shaft system 2, a fine-tuning device 3, a tool holder 4, and a diamond tool 5 , 1394 interface unit 6, stereo microscope system 7, atomic force microscope (AFM) system 8, motor driver 9, AFM controller 10, signal interface unit 11 and measurement and control computer 12, the precision air bearing shaft system 2 is placed vertically In the center of the vibration isolation platform 1, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com