Pneumatic performance testing method as well as pneumatic performance testing device

A technology of aerodynamic performance and test methods, which is used in aerodynamic tests, measurement devices, engine tests, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

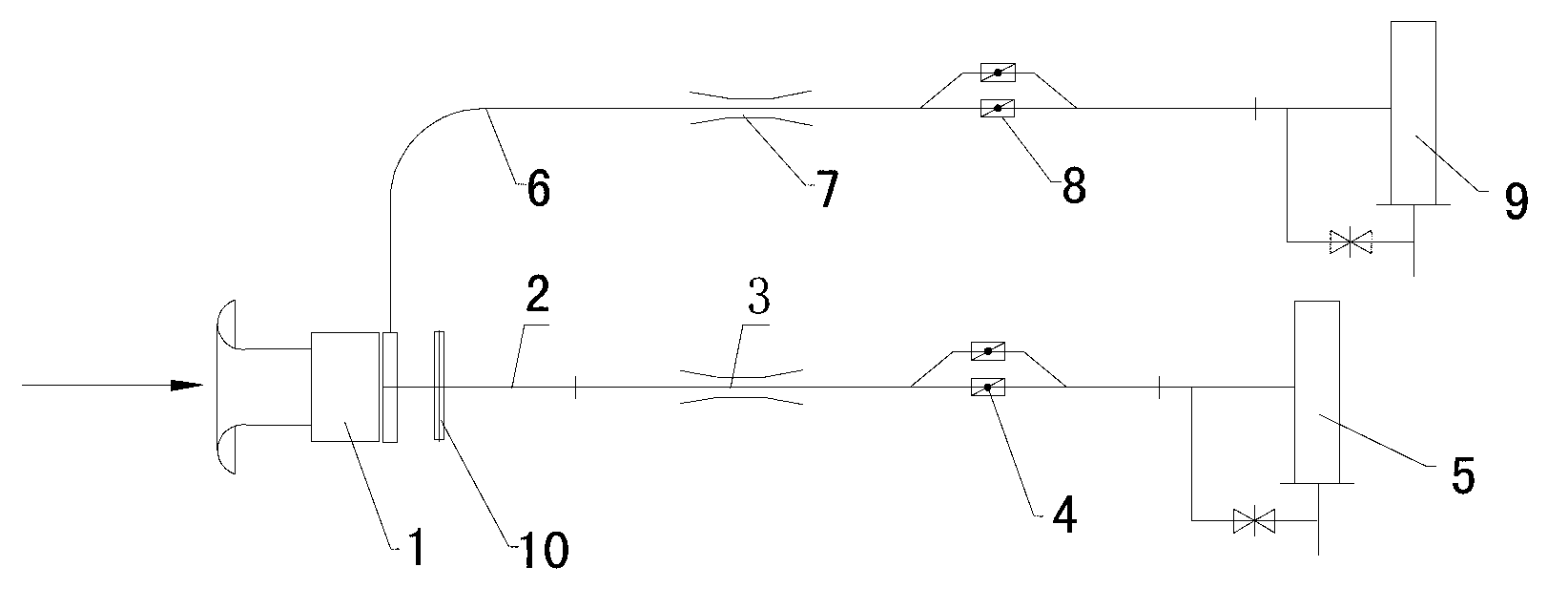

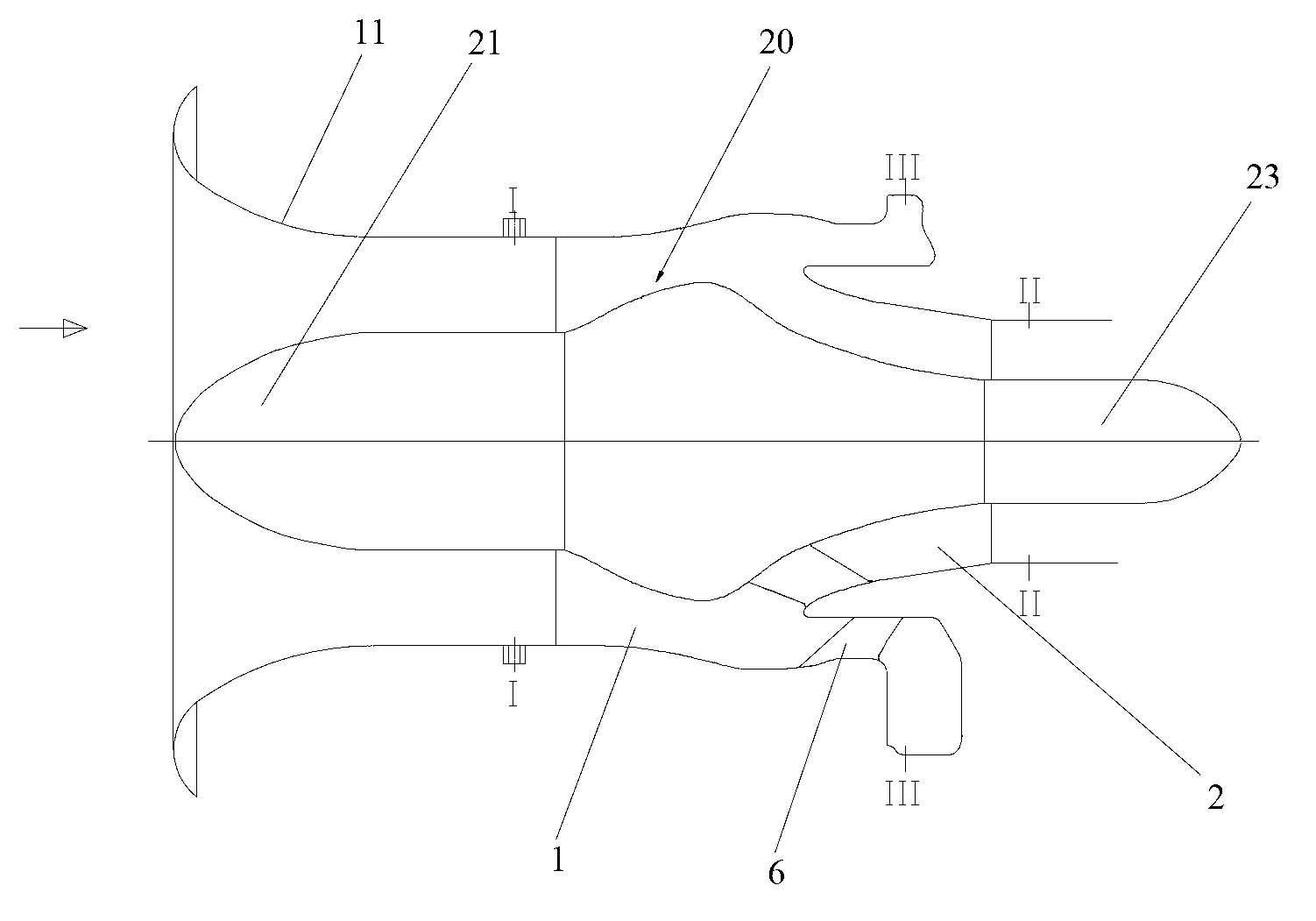

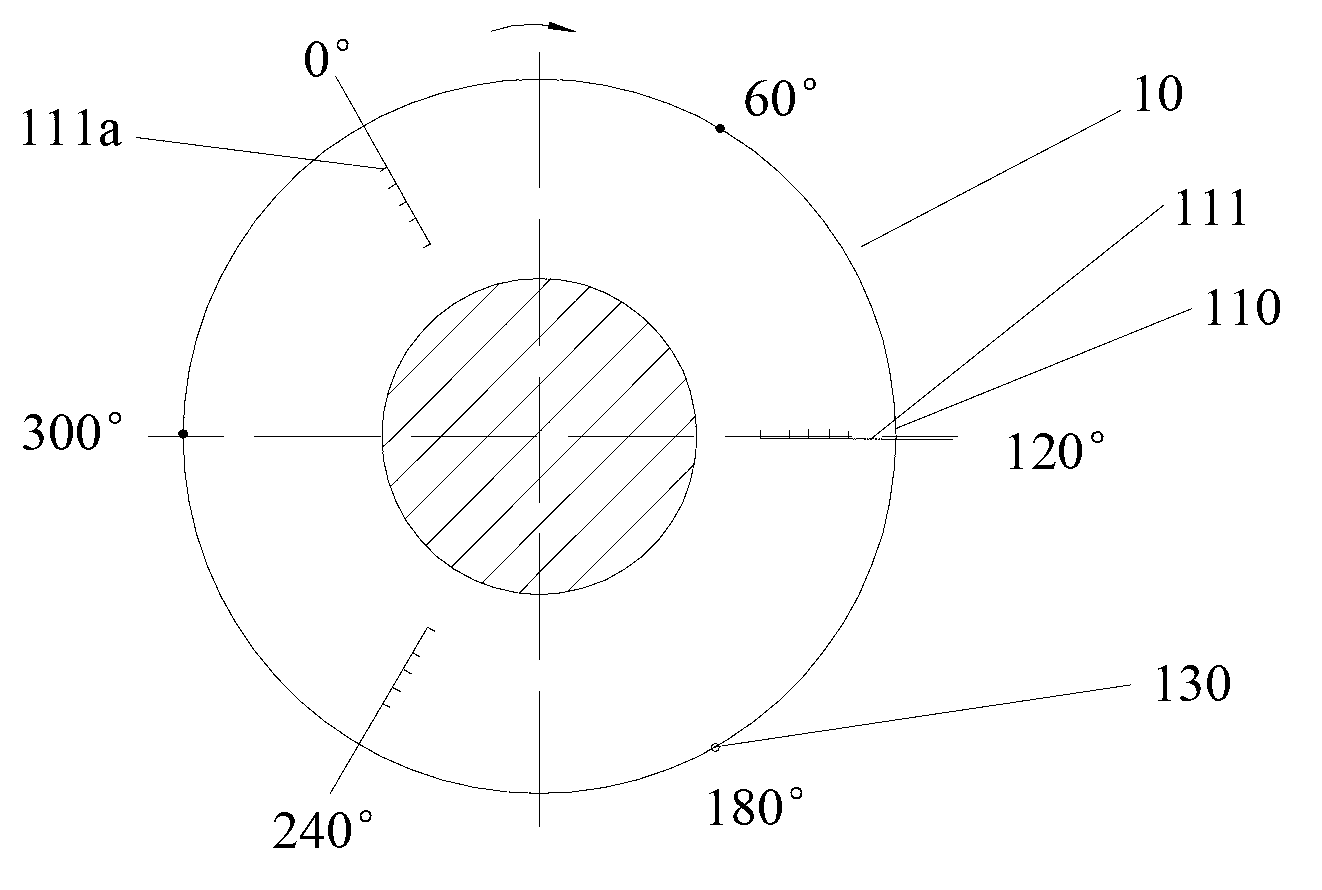

[0043] refer to Figure 1 to Figure 2 , the present invention provides a kind of aerodynamic performance testing device, is suitable for the aerodynamic performance test of particle separator, and this aerodynamic performance testing device comprises: inlet channel 1, main air flow channel 2 and cleaning flow channel 6; main air flow channel 2 and scavenging flow channel 6 are connected to the intake channel 1, along the figure 1 , figure 2 The air flowing into the inlet channel 1 in the direction indicated by the middle arrow passes through the main air flow channel 2 and the purge flow channel 6 and flows out in two ways. In this example, refer to figure 2 , the inner hollow fairing 11 is provided with a cone 20 inside, the axial direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com