Fault diagnosis method for damping springs of vibrating screen

A vibration-damping spring and fault diagnosis technology, which is applied in the field of vibration-damping spring fault diagnosis of vibrating screens, can solve problems such as complex spring vibration diagnosis operations, and achieve the effects of less investment, simple equipment, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

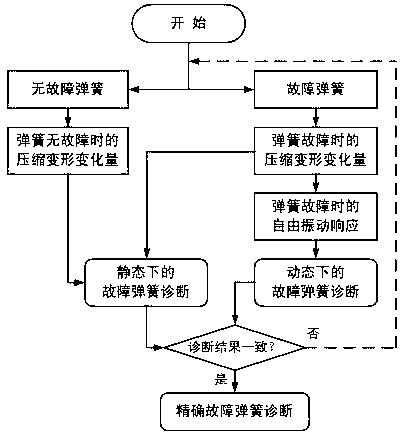

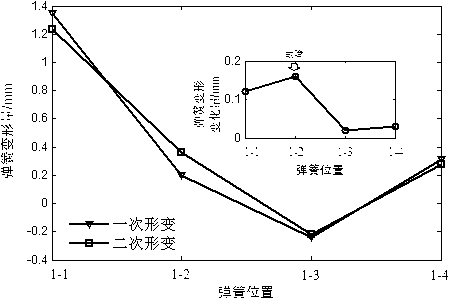

[0024] Embodiment 1: Utilize the value of the measured static deformation of each spring under no fault of the spring to compare with the measured static deformation of each spring after a certain spring fails, to judge the initial fault spring position; and then, to the certain spring after the fault Analyze the measured free vibration response at the four spring supports of the vibrating screen to further accurately determine the location of the faulty spring; the specific steps are as follows:

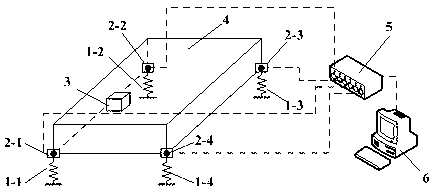

[0025] (1) Hardware layout: in figure 2 Among them, the hardware part includes a displacement sensor, a weight 3, a signal acquisition card 5 and a computer 6 equipped with diagnostic software. Described displacement sensor has the first displacement sensor 2-1, the second displacement sensor 2-2, the 3rd displacement sensor 2-3 and the 4th displacement sensor 2-4; Four displacement sensors are connected by bolt or magnetic seat adsorption Installed on the vibrating screen base, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com