Acidic etching instrument and operation method thereof

A technology of acidizing etching and operation method, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of not representing the actual situation of the reservoir, high cost, difficult experiments, etc. Difficulty, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

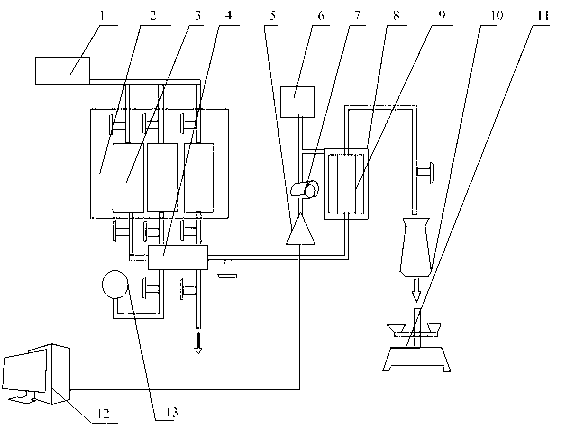

[0047] Such as figure 1 as shown,

[0048] The acidification etching instrument includes a visualized core holder 8 made of transparent material, the visualized core holder 8 is a hollow closed structure, the upper end of the visualized core holder 8 is provided with an upper through hole, and the lower end is provided with a lower through hole , both the upper end through hole and the lower end through hole are connected with the inside of the visualized core holder 8 .

[0049] Sealing pads are provided inside the upper end and the lower end of the above-mentioned visualized rock core holder. Gaskets are used to seal both ends of the core held in the visualization core holder. because. In the actual etching environment. The ends of the core are not etched, but are actually the sides of the core that are etched. The prior art is to perform planar etching. Therefore, all surfaces of the core are subjected to etching treatment, so the experimental data in the later period...

Embodiment 2

[0085] The acidification etching instrument includes a visualized rock core holder 8 made of transparent material. The visualized rock core holder 8 is a cylindrical hollow closed structure. The upper end of the visualized rock core holder 8 has an upper through hole and a lower end. The lower through hole, the upper through hole and the lower through hole all communicate with the inside of the visualized rock core holder 8 .

[0086] It also includes a drain pipe communicated with the through hole at the upper end.

[0087] It also includes a pressure-stabilizing, temperature-stabilizing and acid-stabilizing device communicating with the through hole at the lower end.

[0088] The pressure-stabilizing, temperature-stabilizing and acid-stabilizing device includes a six-way valve 4 connected to the through hole at the lower end. The six-way valve 4 is connected to three liquid storage tanks 3. The liquid storage tanks 3 are placed in the constant temperature water bath 2. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com