Optical fiber bidirectional multi-fire-head control system

A control system and flame head technology, applied in the field of lasers, can solve the problems of easy bending deformation, low coupling efficiency of fiber couplers, etc., and achieve the effects of uniform heating, stable flame temperature, and avoiding fiber bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

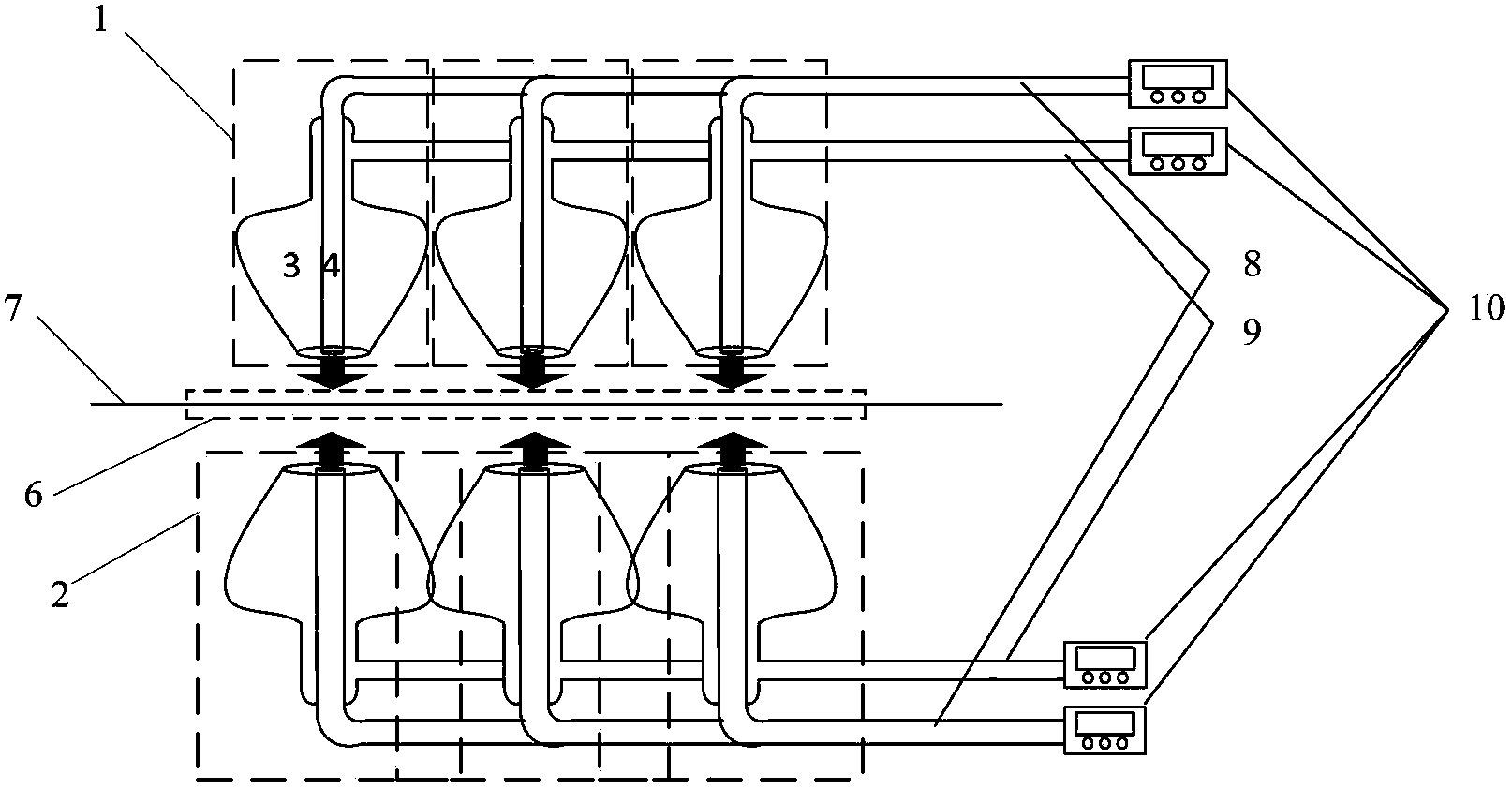

[0023] like figure 1 As shown in the figure, the optical fiber bidirectional multi-burner control system provided by the embodiment of the present invention includes: a plurality of upper burners 1 and a plurality of lower burners 2 arranged oppositely at the top and bottom, and each of the upper burners 1 and the lower burner 2 is connected to a combustible gas The pipeline 8 and the combustible gas pipeline 9; the combustible gas 3 is introduced into the combustible gas pipeline 8; the combustible gas 4 is introduced into the combustible gas pipeline 9.

[0024] The combustible gas pipeline 8 and the combustion-supporting gas pipeline 9 are respectively connected to a gas flow controller 10 for regulating the gas flow; the combustible gas pipeline 8 and the gas-supporting gas pipeline 9 are individually regulated by their respective gas flow controllers 10, so that the combustible gas The gas regulation quantities of the pipeline 8 and the combustion-supporting gas pipeline ...

Embodiment 2

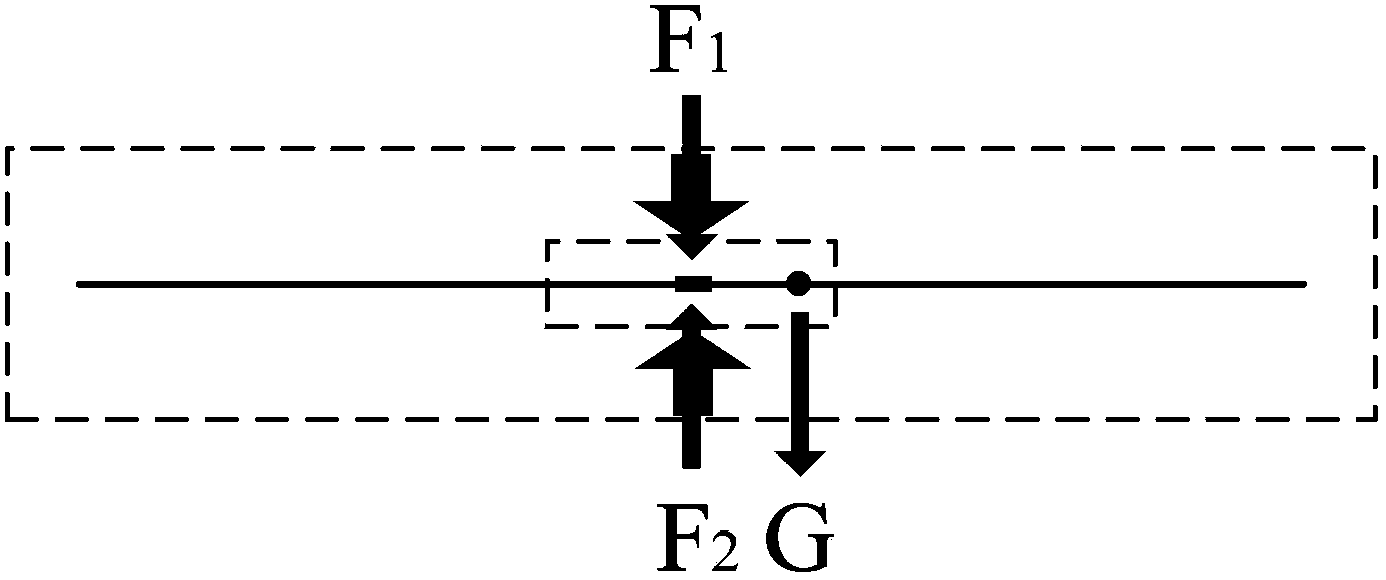

[0029] like image 3 As shown, the difference between this embodiment and the first embodiment is that the nozzle diameter of the lower burner 2 is set larger than that of the upper burner 1 in this embodiment. By adjusting the gas flow controller 10 , the gas flow in the combustible gas pipeline 8 and the combustion-supporting gas pipeline 9 in the lower burner 2 is equal to the gas flow in the combustible gas pipeline 8 and the gas-supporting gas pipeline 9 in the upper burner 1 . The density of the gas ejected by the lower burner 2 and the gas pressure on the optical fibers in the combustion zone 6 are stronger than those of the upper burner, so that the optical fibers in the combustion zone 6 generate upward force. At the same time, due to the downward gravity of the optical fiber itself, the optical fiber subjected to the upward force and its own downward gravity cancel each other, so that the optical fiber is stably placed in a horizontal posture, which can effectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com