Photoelectric-separated intelligent optical fiber connector

A technology of active connectors and electrical connectors, applied in the coupling of optical waveguides, bases/housings, etc., can solve problems such as increased research and development costs, performance is easily affected by the environment, and volume and cost are difficult to reduce, so as to improve product quality and The effect of producing batches, solving intelligent management problems, and reducing production and stocking varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1——4

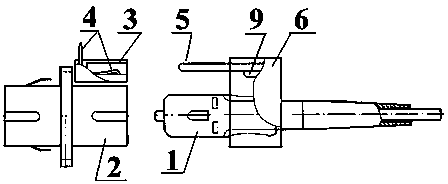

[0028] Example 1-SC type photoelectric separation smart optical fiber active connector indicated by the light guide posts on both sides of the 4-wire slot:

[0029] Such as figure 2 As shown, an electrical connector plug 5 with four golden finger electrical contact points 8 and a contact type electronic label storage chip 9 is fixed on the plug interconnection fixing body 6 through the mounting and fixing slot 11, and is clamped on the SC-type optical fiber movable connector On the movable cover of the plug 1, the gold finger contact point 8 of the electrical connector plug faces the SC-type optical fiber movable connector plug 1, and the exposed electrostatic protection ground 12 is laid on the periphery of the component side of the electrical connector plug 5, and the reverse side is laid bare The ground plane protection layer constitutes a smart optical fiber movable connector plug; four electrical connector elastic contact pins 4 are installed in the independent electrical co...

Embodiment 2

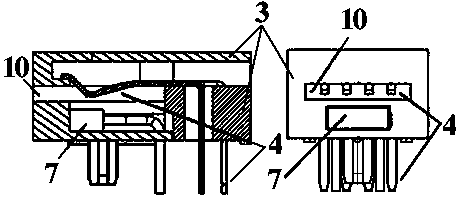

[0030] Example 2-LC type photoelectric separation smart optical fiber active connector indicated by the light guide posts on both sides of the 2-wire slot:

[0031] Such as image 3 As shown, the electrical connector plug 5 with two golden finger electrical contact points 8 and a contact type electronic label storage chip 9 is fixed on the plug interconnection fixing body 6 through the mounting and fixing groove 11, and is clamped on the LC type optical fiber movable connector On the movable cover of the plug 1, the gold finger contact point 8 of the electrical connector plug faces the LC-type optical fiber movable connector plug 1, and the exposed electrostatic protective ground 12 is laid on the periphery of the component side of the electrical connector plug 5, and the reverse side is laid bare The ground plane protection layer constitutes a smart optical fiber movable connector plug; two electrical connector elastic contact pins 4 are installed in the independent electrical co...

Embodiment 3

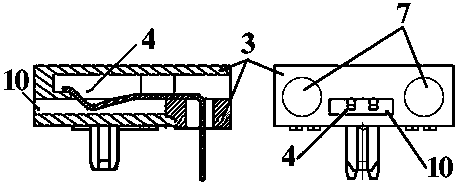

[0032] Example 3-MPO type photoelectric separation smart optical fiber active connector indicated by the LED beside the 3-wire slot:

[0033] Such as Figure 4 As shown, the electrical connector plug 5 with three golden finger electrical contact points 8 and a contact type electronic label storage chip 9 is fixed on the plug interconnection fixing body 6 through the mounting fixing groove 11, and is clamped on the MPO type optical fiber movable connector On the movable cover of the plug 1, the gold finger contact point 8 of the electrical connector plug faces the MPO-type optical fiber movable connector plug 1, and the exposed electrostatic protection ground 12 is laid on the periphery of the component side of the electrical connector plug 5, and the reverse side is laid bare The ground plane protection layer constitutes the intelligent optical fiber movable connector plug; the independent electrical connector socket body 3 is equipped with an electrical connector elastic contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com