Wire breaking method and device for obtaining accurate hanging wire length of overhead transmission line conductor

A technology for overhead transmission lines and wires, applied in the direction of overhead lines/cable equipment, etc., which can solve problems such as instability, line length changes, and repeated adjustments to wire sags, to ensure stability, eliminate extrusion deformation, and shorten consumption. Effect of creep treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 of the disconnecting device provided by the present invention to obtain the accurate hanging length of the overhead transmission line conductor is as follows:

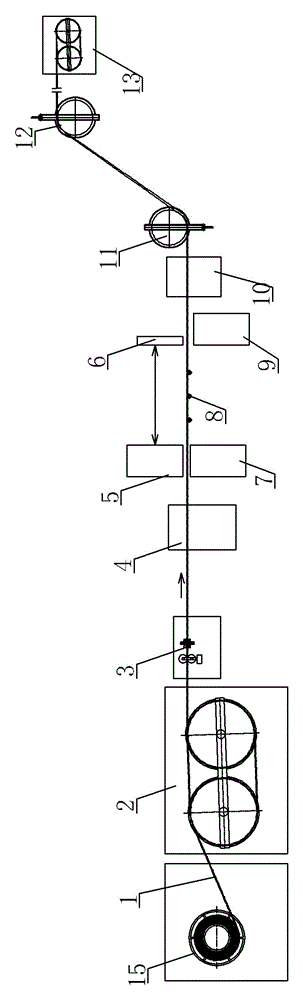

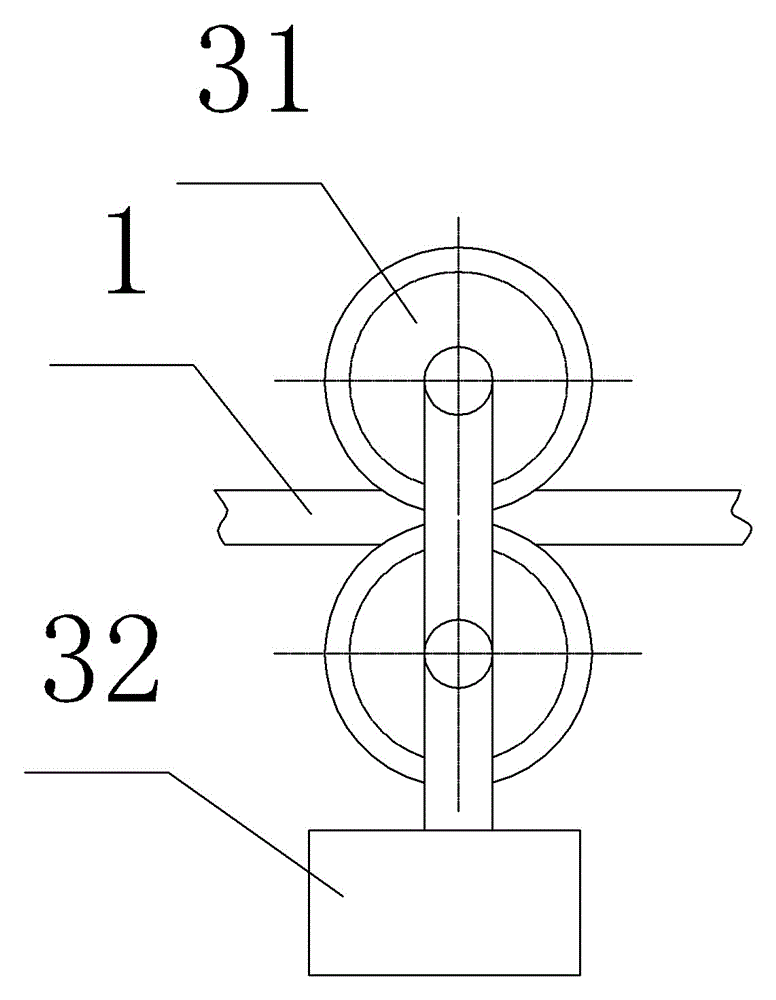

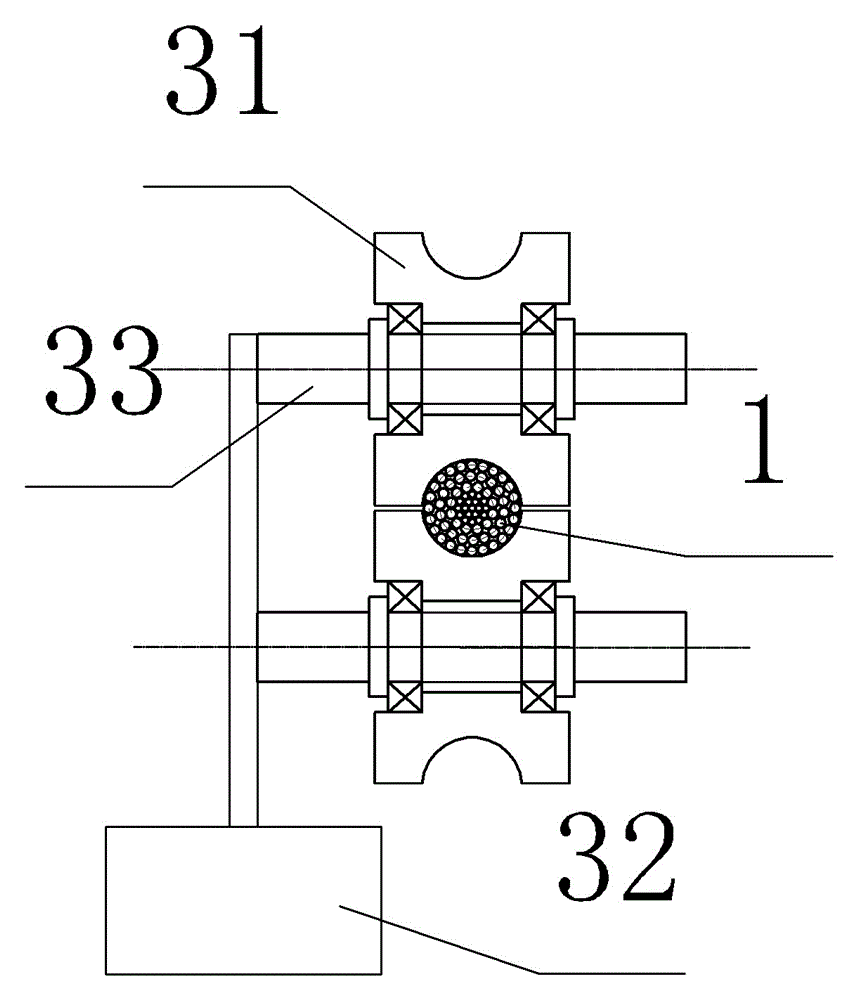

[0040] Figure 1 to Figure 3 The shown disconnecting device for obtaining the accurate hanging length of the overhead transmission line conductor, the device includes a pay-off device and a traction machine 13 arranged at both ends of the head and tail for stretching the wire under tension. After the pay-off device, along the wire 1 In the direction of travel, a vibrating creep elimination station and a length measuring station are arranged in sequence, and two sets of vibrating creep eliminating devices 3 for online vibration and creep elimination of wires are arranged at the vibrating creep eliminating station; at the length measuring station, a length measuring device is arranged. And the tension measuring device 4 used to detect the tension of the wire measuring section, along the direction of t...

Embodiment 2

[0054] Embodiment 2 of the disconnecting device provided by the present invention to obtain the accurate hanging length of the conductor of the overhead transmission line is as follows:

[0055] Figure 5 The shown disconnecting device for obtaining the accurate hanging length of the overhead transmission line conductor, the difference between this device and the embodiment 1 is that the paying-off device 21 adopts a pay-off machine, and adopts a pay-off machine 21 and a wire take-up machine 22 to carry out Tension unwinding, the light reflector 6 of the laser range finder is fixedly connected with the imprint spraying device 7, and the main device 5 of the laser range finder is fixedly connected with the photoelectric sensor 9, because the wire take-up machine 22 adopted is A wire take-up machine capable of producing a larger tension force, so that the wire take-up machine can be used to implement super-tensioning and pre-stretching and anti-creep tension on the wire. In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com