Method for optimizing key parameters of bearingless permanent magnet motor

A technology of permanent magnet motor and key parameters, applied in synchronous machine parts, manufacturing stator/rotor body, etc., can solve the problems of increasing the difficulty and complexity of motor design, achieve short design and development time, clear design ideas, easy to use The effect of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

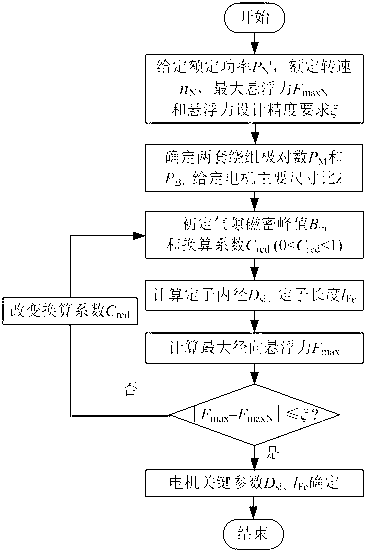

[0015] as the picture shows, figure 1 It is a flow chart of the key parameter optimization design method of the bearingless permanent magnet motor taking into account both the suspension force and the torque, and the figure specifically describes various details in the optimization design process. The specific implementation steps are as follows:

[0016] Step 1: Determine the rated power P of the bearingless permanent magnet motor according to the design requirements N ', rated speed n N , the required maximum suspension force F maxN And the maximum suspension force design accuracy requirements ξ.

[0017] Step 2: Select the number of pole pairs of the two sets of windings of the bearingless permanent magnet motor, that is, the number of pole pairs of the torque winding P M , and the number of pole pairs of the suspension winding is P B , and satisfy P B =P M ±1; select the main size ratio λ of the bearingless permanent magnet motor.

[0018] Step 3: Preliminary selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com