Methods, devices systems for extraction of thermal energy from a heat conducting metal conduit

A pipeline, thermal energy technology, applied in pipeline heating/cooling, household refrigeration devices, control/regulation systems, etc., to solve problems such as broken or damaged pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0363] vertical pipe

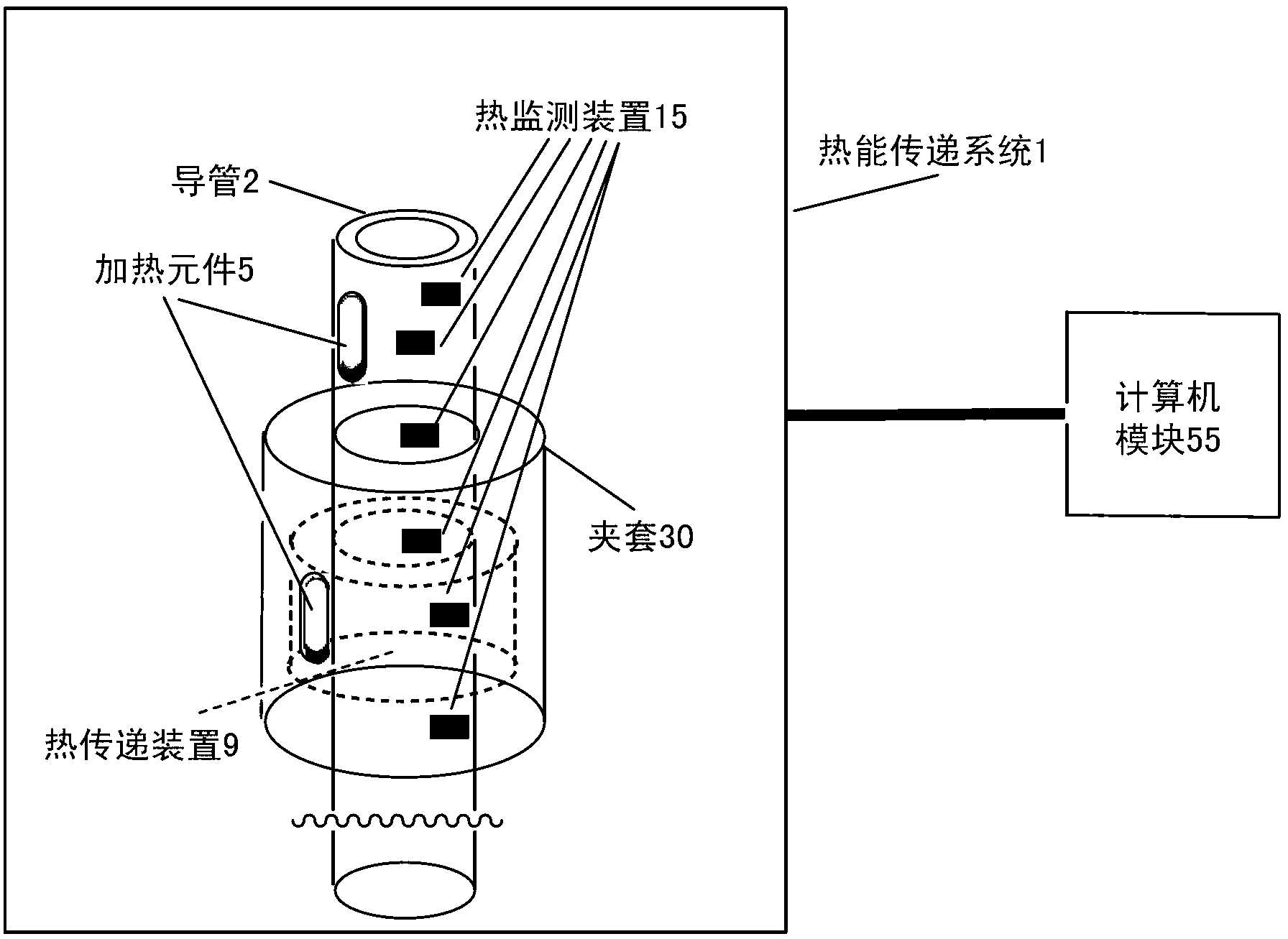

[0364] Fabricate and test the CryoPlug cryothermal valve system on a vertical pipeline. exist Figure 13 An exemplary embodiment is schematically illustrated in . The vertical pipeline configuration of Example 1, described in more detail below, contained floating oil through the system at a flow rate of about 550 barrels per day or 10 feet per second (fps).

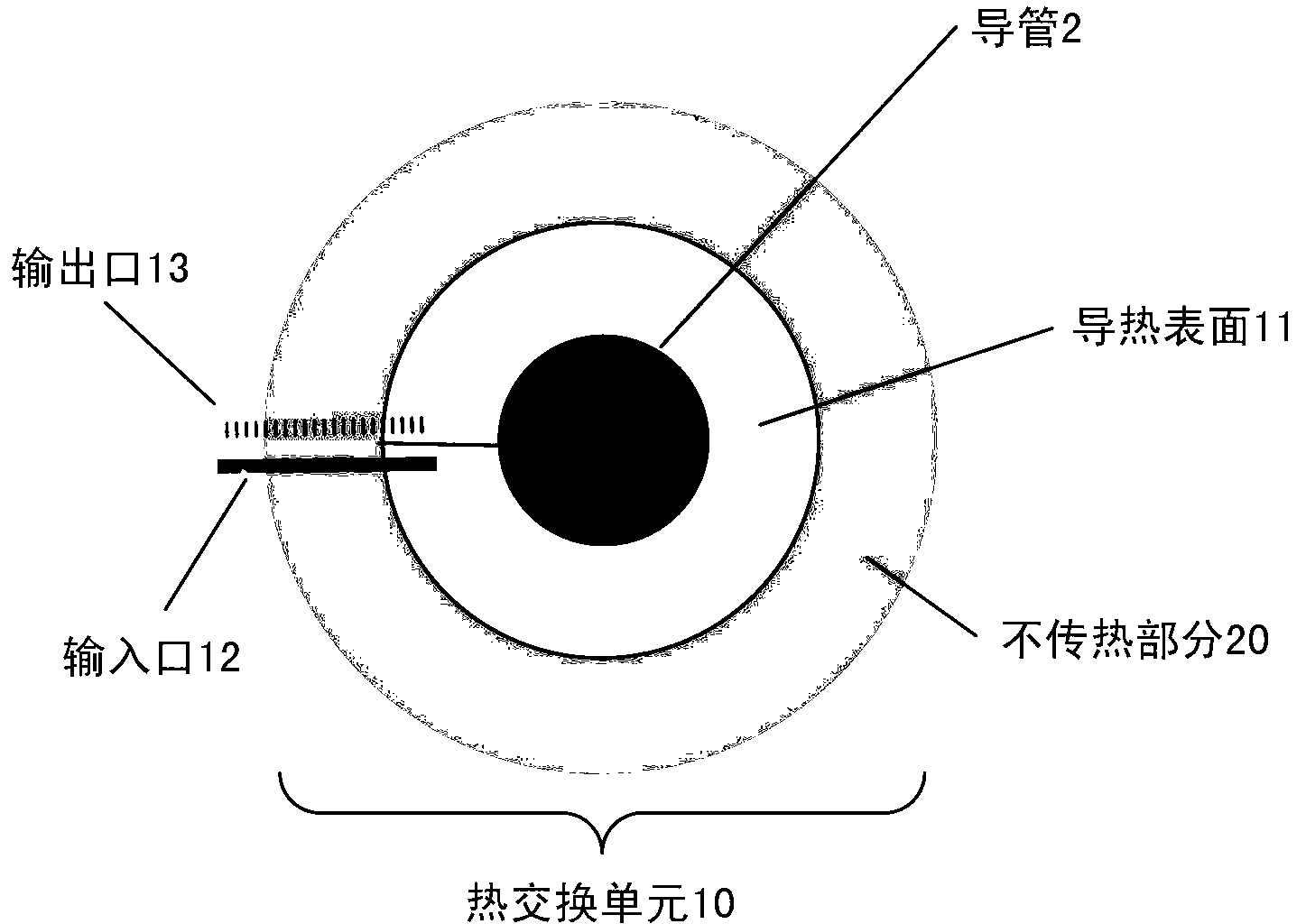

[0365] In this vertical piping system, the system includes a heat exchange unit 10 and a refrigerant injector 67 . In this embodiment, the heat exchange unit 10 includes piping 2 comprising 3 feet carbon steel finned tubes (carbon steel finned tubing, 5 / 8 inch fin height, 1 / 4" fin spacing), 6" section 1a of non-finned carbon steel piping at the top of the finned piping 顶 , and a 6-inch section 1a of non-finned carbon steel piping at the bottom end of the finned piping 底 , to obtain a pipe with a total length of 4 feet. The pipe 2 and each pipe 1a 顶 and 1a 底 A part of it is packed into a ste...

Embodiment 2

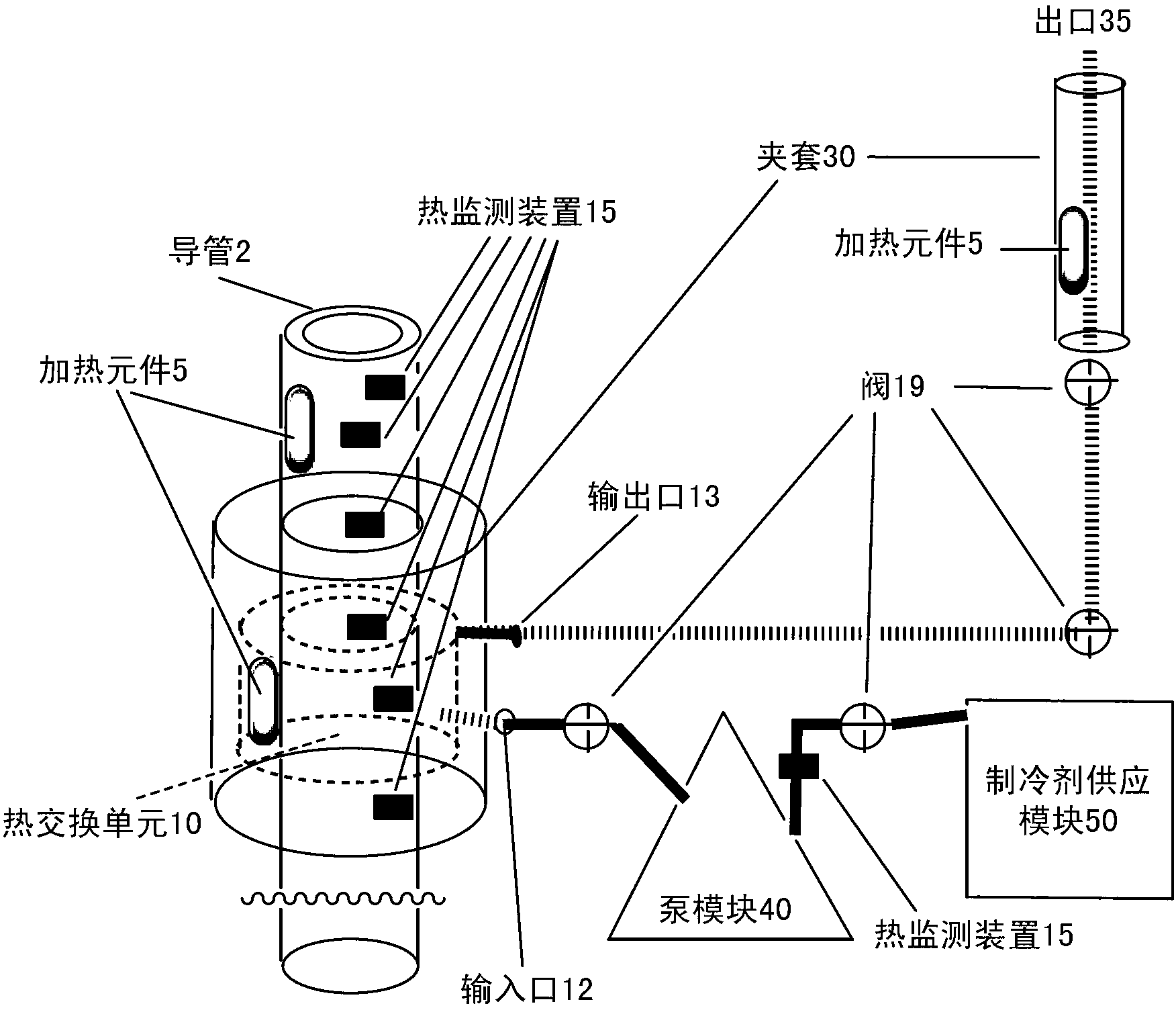

[0375] horizontal pipe

[0376] The CryoPlug cryothermal valve system was fabricated and tested on horizontal piping. exist Figure 14A and 14B An exemplary embodiment is schematically illustrated in .

[0377] In this horizontally oriented piping system, the system includes a heat exchange unit 10 and a refrigerant injector 60, an enlarged view of which is shown in Figure 14A shown. In this embodiment, the heat exchange unit 10 includes tubing 2 comprising 6 feet of 304 stainless steel finned tube 2f (stainless steel finned tubing, 3 / 4 inch fin height, 1 / 4 inch fin spacing), and a 12 inch non-finned stainless steel piping section 2a at the left end of the finned piping 2f 左 , and the 12-inch non-finned stainless steel piping section 2a at the right end 右 , to obtain a pipe with a total length of 8 feet. Finned tube 2f and each tube 2a 左 and 2a 右 A part of it is packed into a carbon steel pipe 2c with a diameter of 5 inches as a jacket. 1 / 8 inch steel plate 3 with o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com