Ear-picking and straw-cutting unit body

A technology for cutting units and units, which is applied in the direction of cutters, agricultural machinery and implements, applications, etc., can solve the problems of low moisture content, inability to meet bundling and recycling, etc., and achieve strong adaptability, obvious cutting effect, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

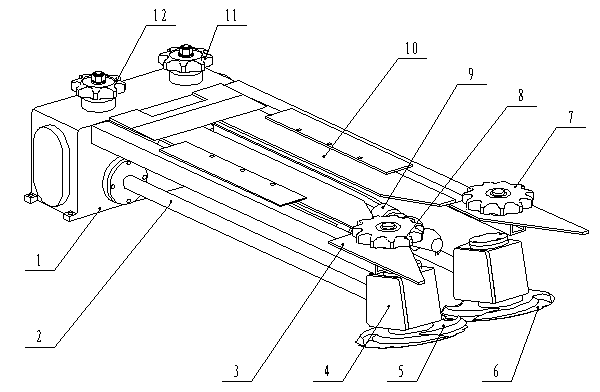

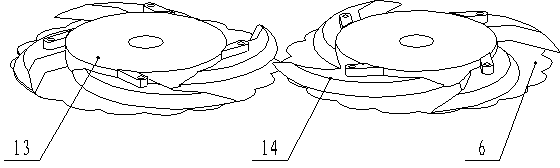

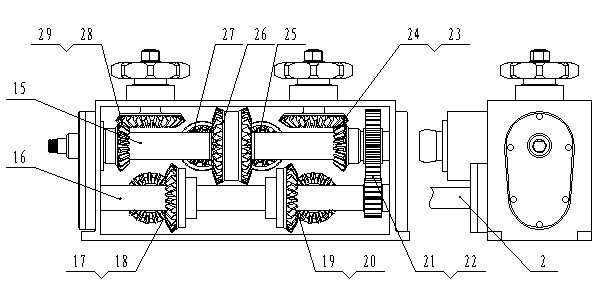

[0015] Such as Figure 1 ~ Figure 4 Shown: the ear-picking straw cutting unit mainly includes the grain dividing device 3, the ear picking device, the straw cutting device and the transmission part. The bottom of the box 4 and the small gearbox 4 are connected with the straw cutting device. The straw cutting device includes a moving knife 5 and a fixed knife 6. The moving knife 5 is above the fixed knife 6. Behind the grain dividing device 3 is an ear picking device. The ear picking device includes A pair of stem-pull rollers 9 and fringe-picking plates 10, the stem-pull rollers 9 are positioned side by side below the fringe-picking plate 10, the two stem-pull rollers 9 rotate oppositely, the stem-pull rollers 9 are connected to the main gearbox 1 behind it, and the main gearbox 1 The two long shafts 2 below the ear picking device are connected to the two small gearboxes 4 below the grain dividing device 3, the main gearbox 1, the small gearbox 4, the sprockets 7, 8 abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com