Inferior sulfolane regenerator

A regeneration device, sulfolane technology, applied in ion exchange regeneration, ion exchange treatment device, ion exchange and other directions, can solve the problems of small distribution elements with small flux, unusable, difficult to repair and replace, etc., to ensure effective linear flow rate, The effect of long service life and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

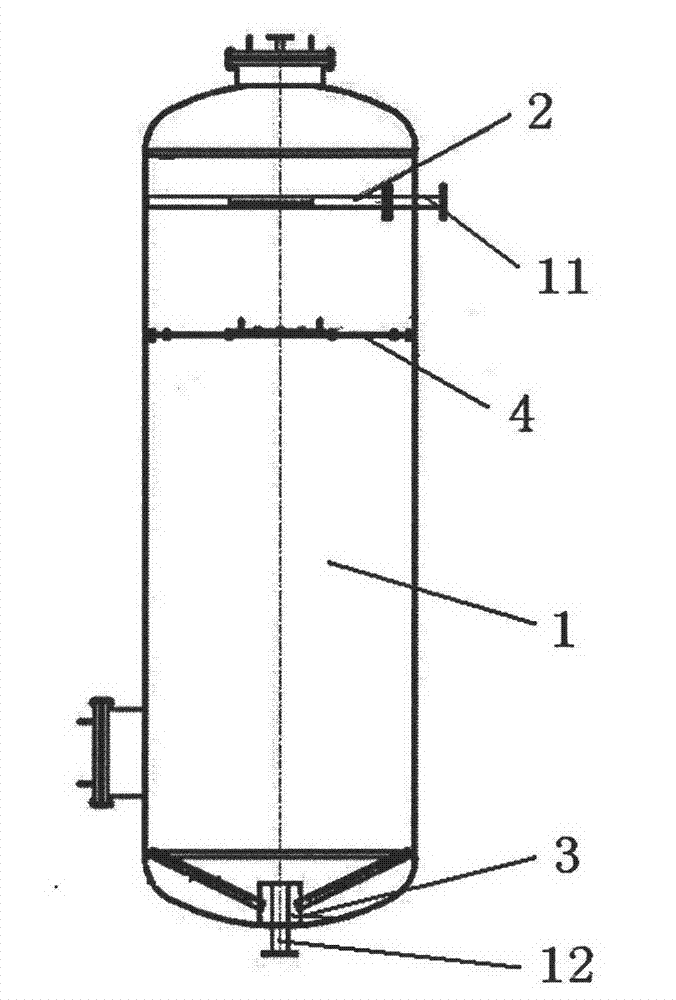

[0042] Refer to attached Figure 1 to Figure 11 shown;

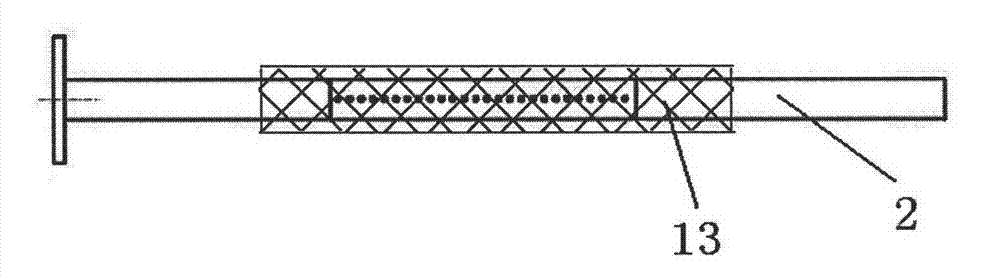

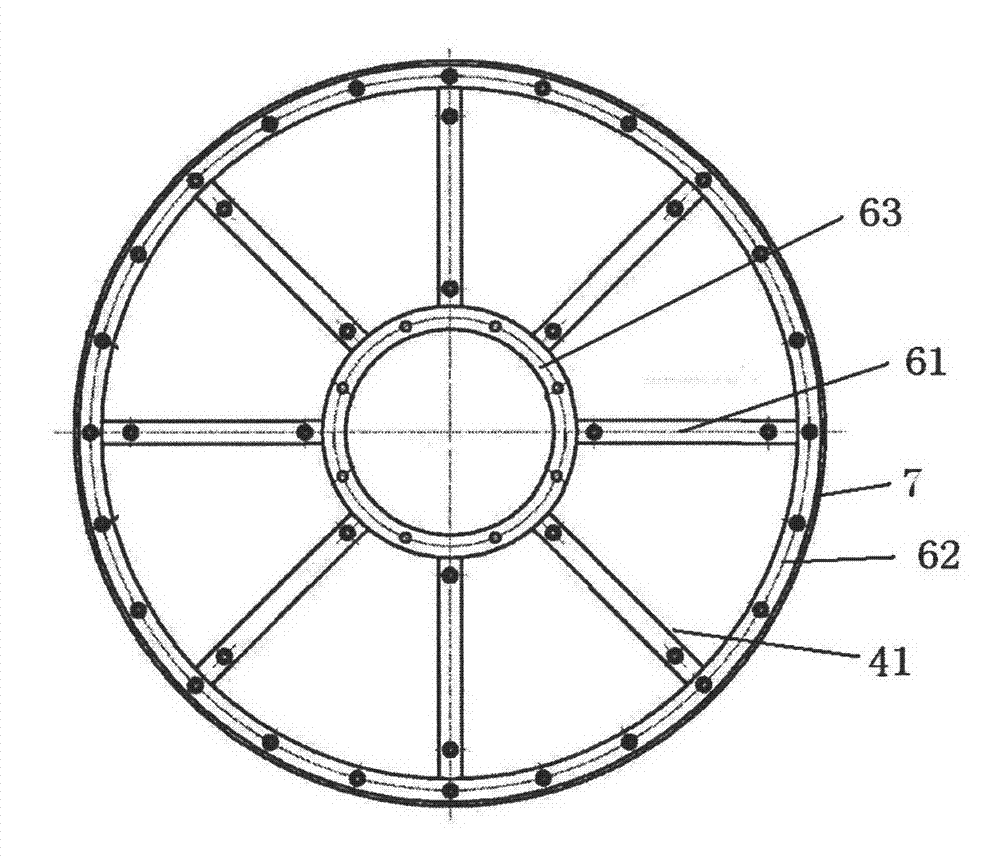

[0043] A kind of low-quality sulfolane regeneration device, comprising a resin tower 1, which is a vertical cylinder structure, the feed port 11 of the resin tower 1 is provided with an upper distributor 2, and the discharge port 12 of the resin tower 1 is provided with a lower distributor 3, in A wire mesh distributor 4 is provided between the upper distributor 2 and the lower distributor 2 to keep the ion exchange resin in a relatively fixed position.

[0044] A support ring 7 is fixed on the barrel wall of the resin tower 1, the support ring 7 is a stainless steel ring, the outer diameter is the same as the inner diameter of the resin tower 1, and the wire mesh distributor 4 is fixed on the support ring 7 by bolts; the support ring 7 is directly welded on On the inner wall of the resin tower 1, at a position of 150-230 mm on the surface of the ion exchange resin, to leave enough space for backwashing and expansion of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com