Fin slope machining device

A technology of groove processing and fin placement of molds, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc. Low requirements for welding technology, improved welding manufacturability and convenient welding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

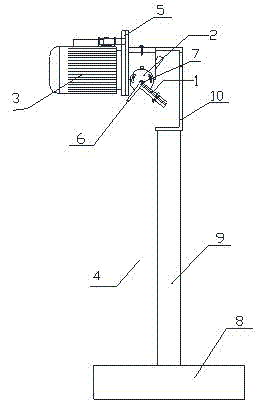

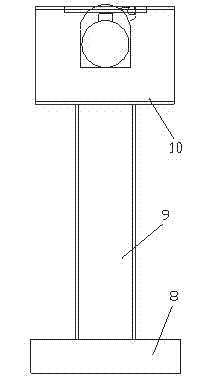

[0010] Such as figure 1 , figure 2 Shown: a fin groove processing device, which includes a fin placement mold 1, an adjustment plate 2, a motor 3, a bracket 4, a connecting plate 5, a baffle plate 6 and a milling power head 7, the bracket includes a flat plate 8, The vertical plate 9 and the channel steel 10, the vertical plate 9 is vertically arranged on the upper part of the flat plate 8, the upper part of the vertical plate 9 is connected to one side of the channel steel 10, and the front part of the channel steel 10 is connected with the milling power head 7, the connecting plate 5 and the motor 3 in sequence One side of the milling power head 7 is connected with an adjustment plate 2, the adjustment plate 2 is circular and has a V-shaped notch, the notch faces outward, one side of the notch is connected with a fin to place the mold 1, and the other half of the notch is connected with a The baffle plate 6 and the mold for placing the fins are a flat plate with grooves tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com