Lignin-based amphiphilic azo-polymer colloidal spheres as well as preparation method and application thereof

An azo polymer and lignin-based technology, which is applied in the field of derivatives of natural polymer compounds, can solve the problem of high preparation cost of azo polymer colloidal balls, and achieve the effects of improving utilization value, promoting enthusiasm, and reducing preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

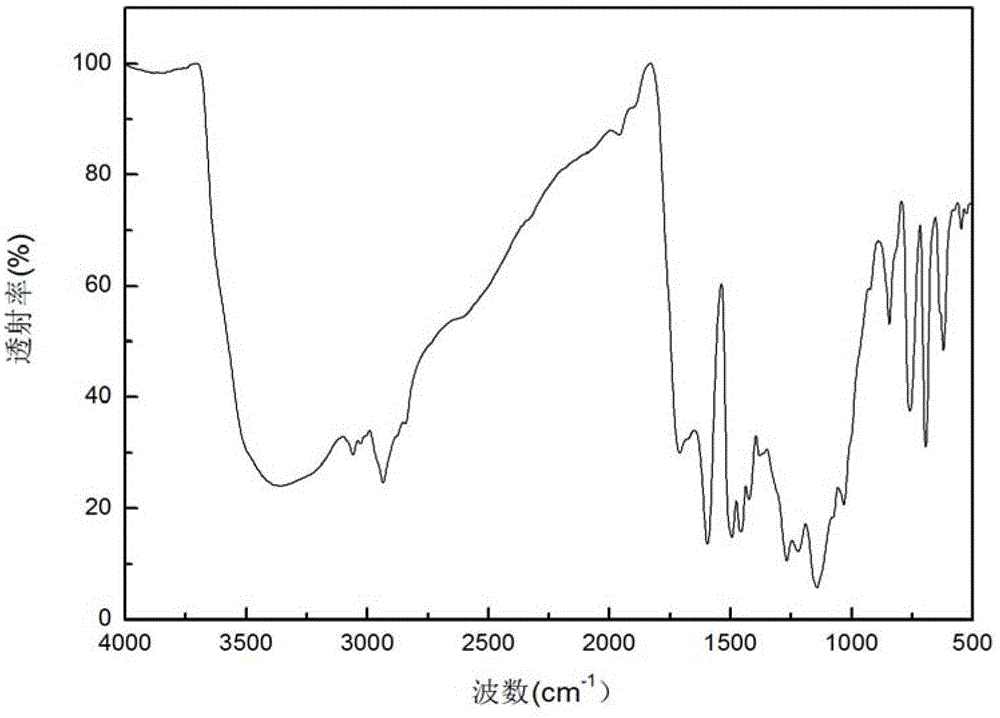

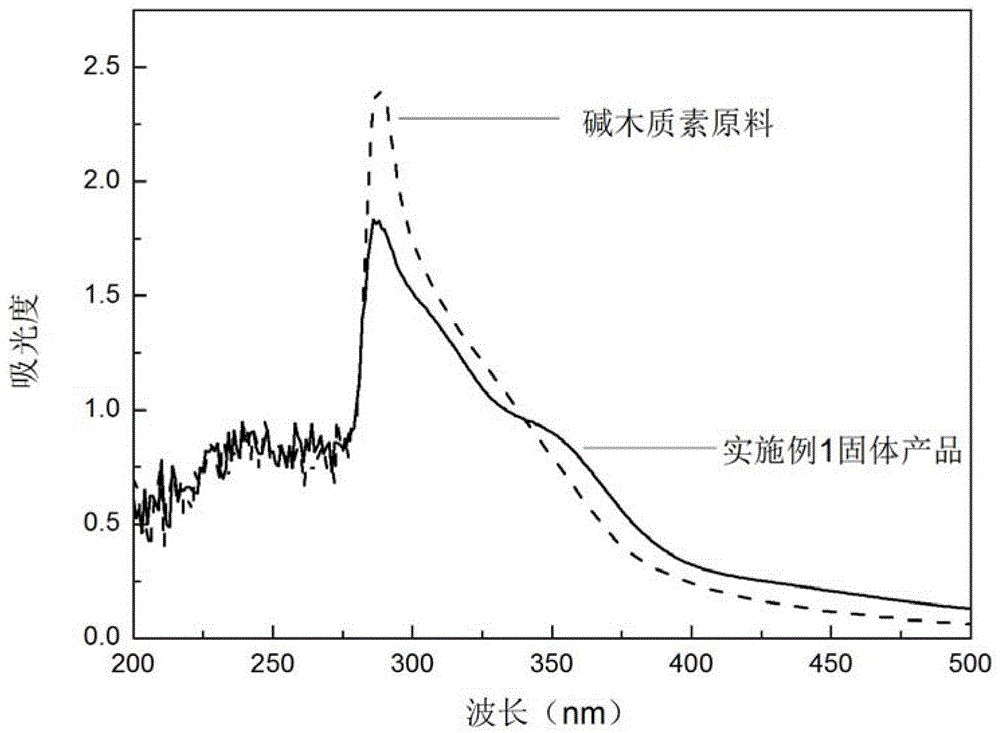

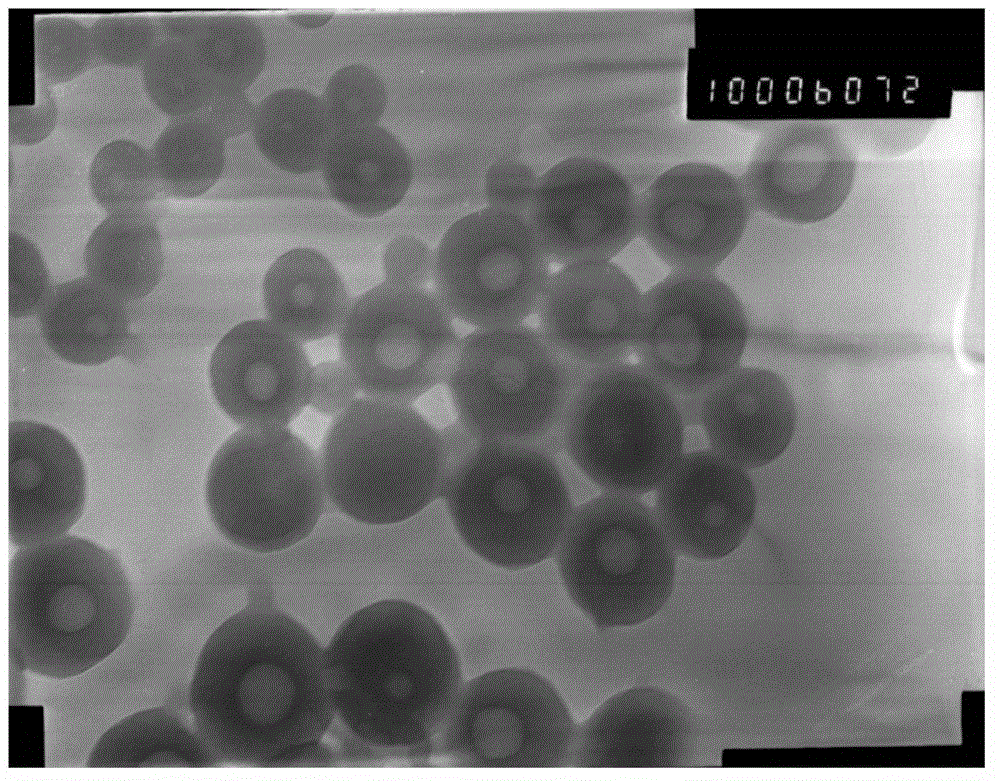

[0035] Take 1.8g (containing 6mmol benzene ring unit) alkali lignin, dissolve in 200mL NaOH solution (1.0×10 -4 mol / L), under the condition of 85° C. water bath, 0.32 g of hydrogen peroxide with a mass percentage of 30% was added dropwise, reacted for 1.5 h and then cooled to room temperature to obtain demethoxylized alkali lignin.

[0036] Weigh 0.744g of aniline (8mmol) and dissolve it in 25mL of ethanol, add 10mL of 0.117g / mL dilute sulfuric acid (12mmol) dropwise to the solution, and stir the reaction at 100r / min at 0°C for 20min. Then, under stirring, dropwise add 5mL 0.175g / mLNaNO 2 Solution (8.5mmol), continue to react for 1.5h to obtain the corresponding diazonium salt.

[0037] Mix the oxidized alkali lignin with the diazonium salt prepared above, add 3% NaOH solution to adjust the pH to 10, and stir at 0° C. at 100 r / min to continue the reaction for 1.5 h. 2g / mL sulfuric acid was added dropwise to adjust the pH of the solution to 3, and the product was precipitated b...

Embodiment 2

[0045] Take 1.8g (containing 6mmol benzene ring unit) alkali lignin, dissolve in 200mL NaOH solution (1.0×10 -4 mol / L), under the condition of 95°C water bath, 0.36 g of hydrogen peroxide with a mass percentage of 25% was added dropwise, reacted for 1 hour, and then cooled to room temperature to obtain demethoxylized alkali lignin.

[0046] Weigh 1.112g p-nitroaniline (8mmol) and dissolve it in 30mL ethanol, add 10mL 0.117g / mL dilute sulfuric acid (12mmol) dropwise to the solution, and stir the reaction at 120r / min at 0°C for 20min. Then, under stirring, dropwise add 5mL 0.175g / mLNaNO 2 Solution (8.5mmol), continue to react for 1h to obtain the corresponding diazonium salt.

[0047] Mix the oxidized alkali lignin with the diazonium salt prepared above, add 3% NaOH solution by mass to adjust the pH to 12, and stir at 0°C at 120r / min to continue the reaction for 1h. 2g / mL hydrochloric acid was added dropwise to adjust the pH of the solution to 2, and the product was precipitat...

Embodiment 3

[0052] Take 1.8g (containing 6mmol benzene ring unit) alkali lignin, dissolve in 200mL NaOH solution (1.0×10 -4 mol / L), under the condition of 85° C. water bath, 0.36 g of hydrogen peroxide with a mass percentage of 35% was added dropwise, reacted for 1 hour, and then cooled to room temperature to obtain demethoxylized alkali lignin.

[0053] Weigh 1.11g of p-aminobenzoic acid (8mmol) and dissolve it in 20mL of ethanol, add 10mL of 0.117g / mL dilute sulfuric acid (12mmol) dropwise to the solution, and stir the reaction at 120r / min at 0°C for 20min. Then, under stirring, dropwise add 5mL 0.175g / mLNaNO 2 Solution (8.5mmol), continue to react for 1h to obtain the corresponding diazonium salt.

[0054] The oxidized alkali lignin was mixed with the diazonium salt prepared above, and the pH was adjusted to 9 by adding 3% NaOH solution by mass percentage, and the reaction was continued for 1 h at 0° C. with stirring at 100 r / min. 2g / mL sulfuric acid was added dropwise to adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com