Binding tape

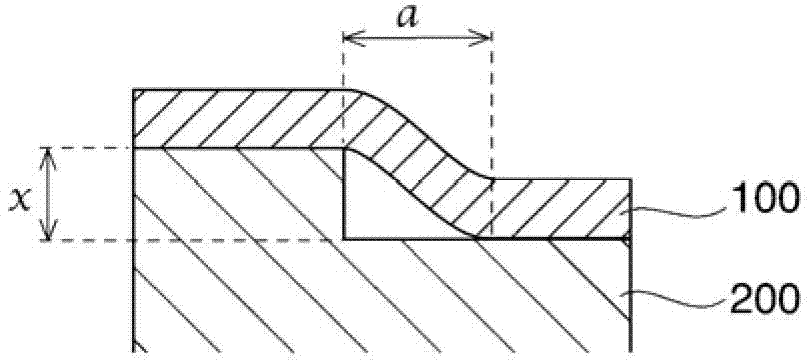

An adhesive tape and adhesive layer technology, applied in the direction of adhesives, film/sheet adhesives, electrical components, etc., can solve adhesive residues, damage to semiconductor wafers, insufficient height difference followability, etc. problem, to achieve the effect of fewer steps and excellent followability of height differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

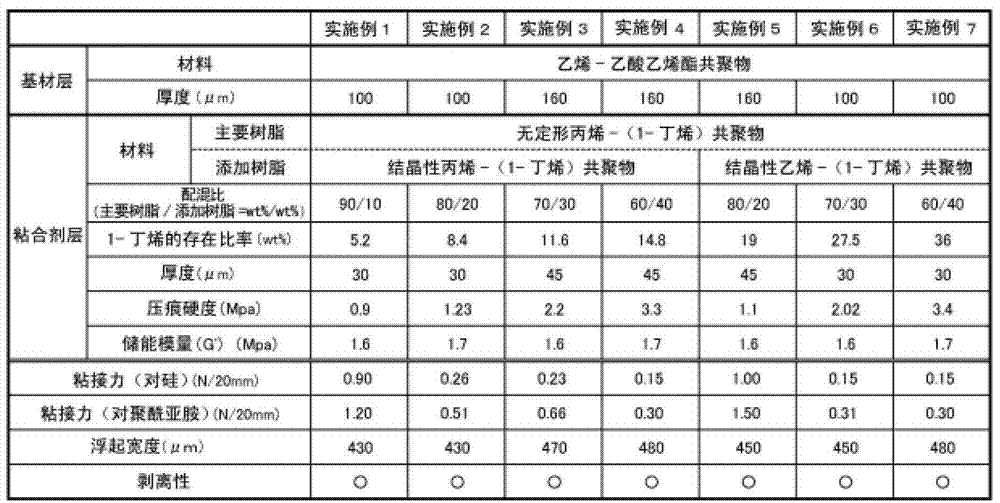

[0076] As an adhesive layer forming material, an amorphous propylene-(1-butene) copolymer (manufactured by Sumitomo Chemical Co., trade name "Tafthren H5002", derived from 1-butene) containing 90 parts by metallocene catalyst polymerization was used. structural unit: 2% by weight), and 10 parts of crystalline propylene-(1-butene) copolymer (manufactured by Mitsui Chemicals, trade name "TAFMER XM7070", structural unit derived from 1-butene: 34% by weight) (total content ratio of structural units derived from 1-butene in the resin composition: 5.2% by weight).

[0077] As the substrate layer forming material, an ethylene-vinyl acetate copolymer (manufactured by DuPont-Mitsui Co., Ltd., trade name "EVAFLEX P1007") was used.

[0078] The above-mentioned adhesive layer forming material and base material layer forming material were charged into respective extruders, and T-die melt coextrusion was carried out (extruder: manufactured by GM Engineering, trade name "GM30-28" / T-die : Cl...

Embodiment 2

[0080]As an adhesive layer forming material, an amorphous propylene-(1-butene) copolymer (manufactured by Sumitomo Chemical Co., trade name "Tafthren H5002", derived from 1-butene) containing 80 parts by metallocene catalyst polymerization was used. structural unit: 2% by weight), and 20 parts of crystalline propylene-(1-butene) copolymer (manufactured by Mitsui Chemicals, trade name "TAFMER XM7070", structural unit derived from 1-butene: 34% by weight) (total content ratio of structural units derived from 1-butene in the resin composition: 8.4% by weight), except that, it was carried out in the same manner as in Example 1 to obtain an adhesive tape.

Embodiment 3

[0082] As an adhesive layer forming material, an amorphous propylene-(1-butene) copolymer (manufactured by Sumitomo Chemical Co., trade name "Tafthren H5002", derived from 1-butene) containing 70 parts by metallocene catalyst polymerization was used. structural unit: 2% by weight), and 30 parts of crystalline propylene-(1-butene) copolymer (manufactured by Mitsui Chemicals, trade name "TAFMER XM7070", structural unit derived from 1-butene: 34% by weight) (total content ratio of structural units derived from 1-butene in the resin composition: 11.6% by weight), the thickness of the adhesive layer is 45 μm, and the thickness of the substrate layer is 160 μm. In addition, with Embodiment 1 was operated similarly to obtain an adhesive tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com