Wavy chemical fiber bundle forming machine

A chemical fiber and wavy technology, which is applied in the field of wavy chemical fiber bundle forming machines, can solve the problems of high temperature, short service life, high noise, etc., and achieve the effects of small vibration, extended working life and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

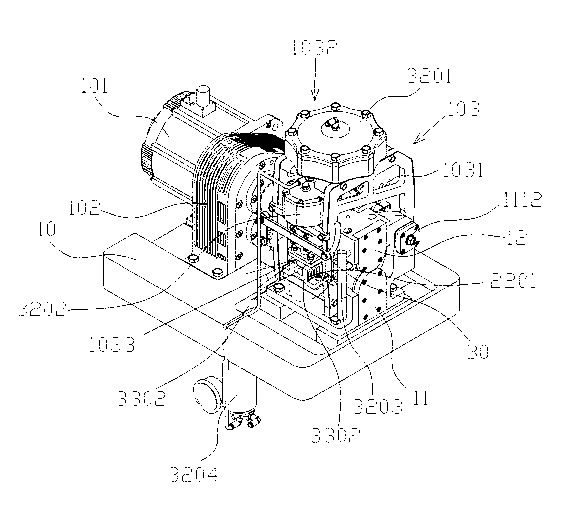

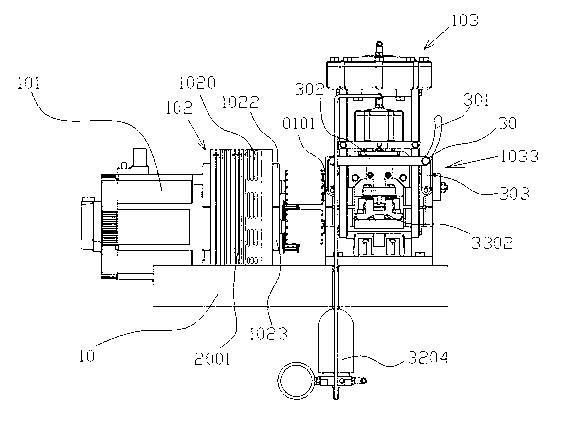

[0020] Figure 1 to Figure 3 A wave-shaped chemical fiber bundle forming machine according to an embodiment of the present invention is schematically shown.

[0021] Such as figure 1 and image 3 As shown, the corrugated chemical fiber bundle forming machine of the present invention includes: a main body 10, a main motor 101, a transmission mechanism 102 and an actuator 103; In this embodiment of the invention, the main motor 101 is a servo motor.

[0022] The forming mechanism 1033 includes a pair of pressing rollers and a forming part 3302, the pressing rollers are located in front of the input end of the forming part 3302; the thread adjusting frame 3303 is arranged in front of the pressing rollers to arrange the thickness of the fiber bundles evenly; the wet spraying mechanism 1031 is located at the input end of the pressing ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com