Device for evaluating oil absorbency of granular adsorbing material

An adsorption material and evaluation device technology, which is applied in the direction of analyzing materials, using substances to absorb and weighing, instruments, etc., can solve the problems of no test evaluation device, difficult to popularize and use, and strong subjective experience, so as to achieve convenient and direct reading, Accurate and reliable adsorption capacity and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

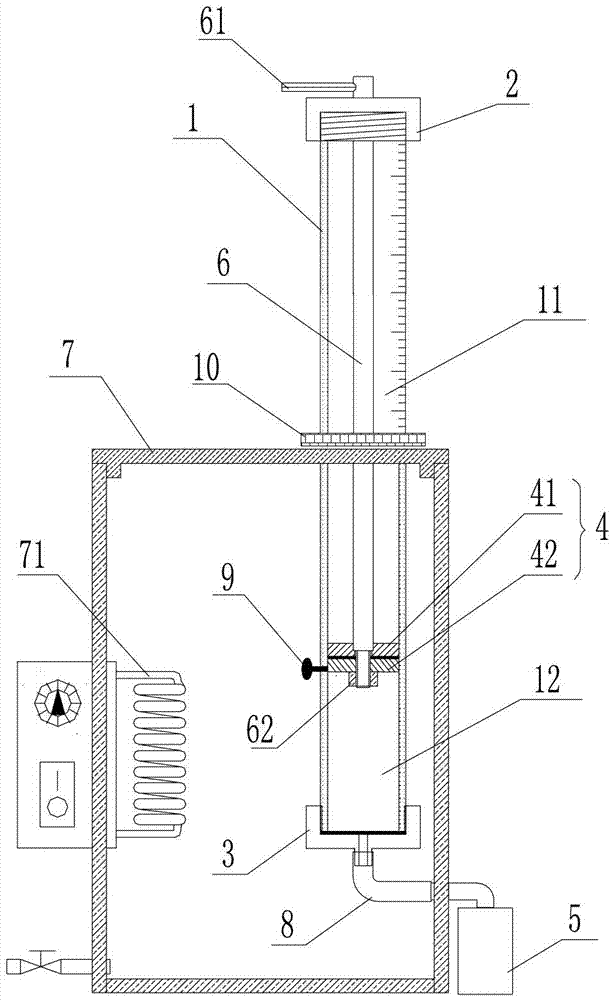

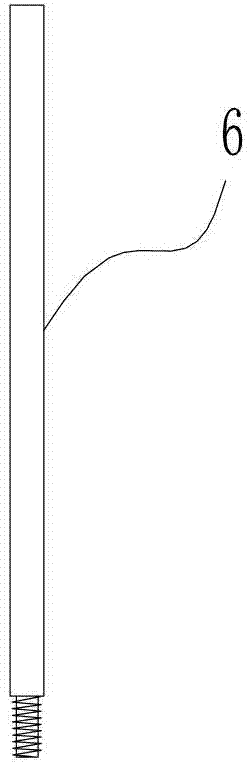

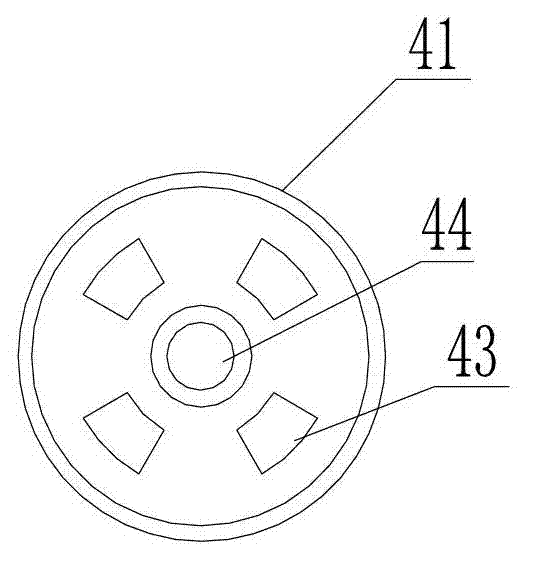

[0035] Please refer to Figure 1 to Figure 4 , are respectively the structural schematic diagram of Embodiment 1 of the device for evaluating the oil absorption performance of the particle adsorption material of the present invention; the structural schematic diagram of the control rod of the present invention; the structural schematic diagram of the upper baffle plate of the oil baffle assembly of the present invention; Schematic diagram of the structure of the lower baffle. As shown in the figure, the present invention proposes an evaluation device for the oil-absorbing performance of granular adsorption materials, including an adsorption column 1, an oil retaining plate 4, an oil collection container 5, a control rod 6, and a water heating container 7. Such as figure 1 As shown, the adsorption column 1 has a scale mark and is vertically arranged. The adsorption column 1 has an upper port and a lower port. The upper port of the adsorption column 1 is provided with a top cov...

Embodiment 2

[0064] Please refer to Figure 5 , is a schematic structural diagram of Embodiment 2 of the present invention. In this embodiment, the same components as those in Embodiment 1 use the same reference numerals.

[0065] Such as Figure 5 As shown, the main structure, working principle and beneficial effects of the second embodiment of the present invention are the same as those of the first embodiment, and will not be repeated here. The only difference is that the second embodiment is not provided with a water heating container. When the oil product used in the detection is diesel oil, it is not necessary to heat it, so the device removes the water heating container. In order to fix the device, a bracket 100 is provided, and the adsorption column 1 is inserted through the socket of the bracket 100 , and fixed with the bracket 100 through the clamp 10 .

[0066] When in use, the second embodiment adopts the following steps:

[0067] Step 1: Add the granular adsorbent that has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com