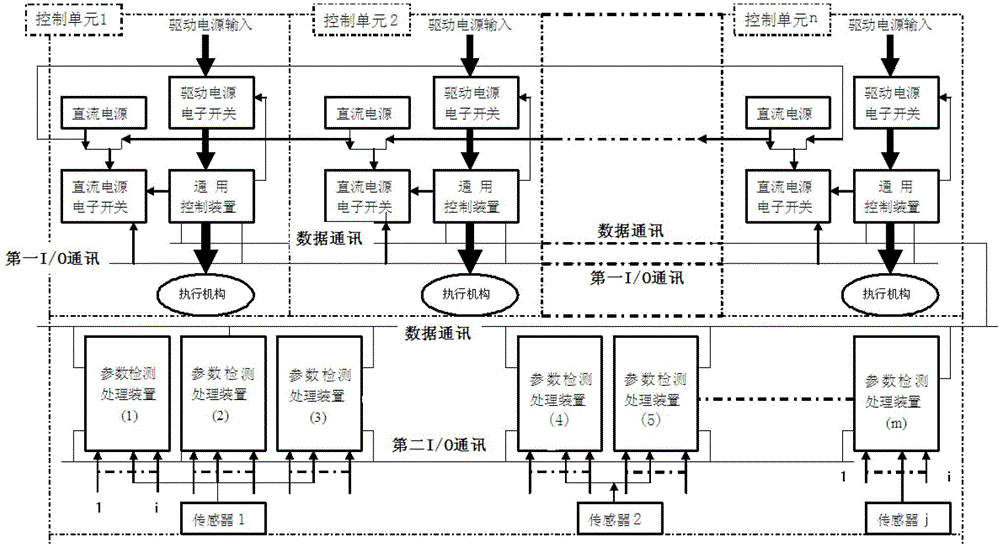

Industrial online maintenance-free control system

A control system, maintenance-free technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of high economic cost, large hardware composition, complex structure, etc., to reduce malignant accidents, ensure normal operation, The effect of online maintenance-free improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

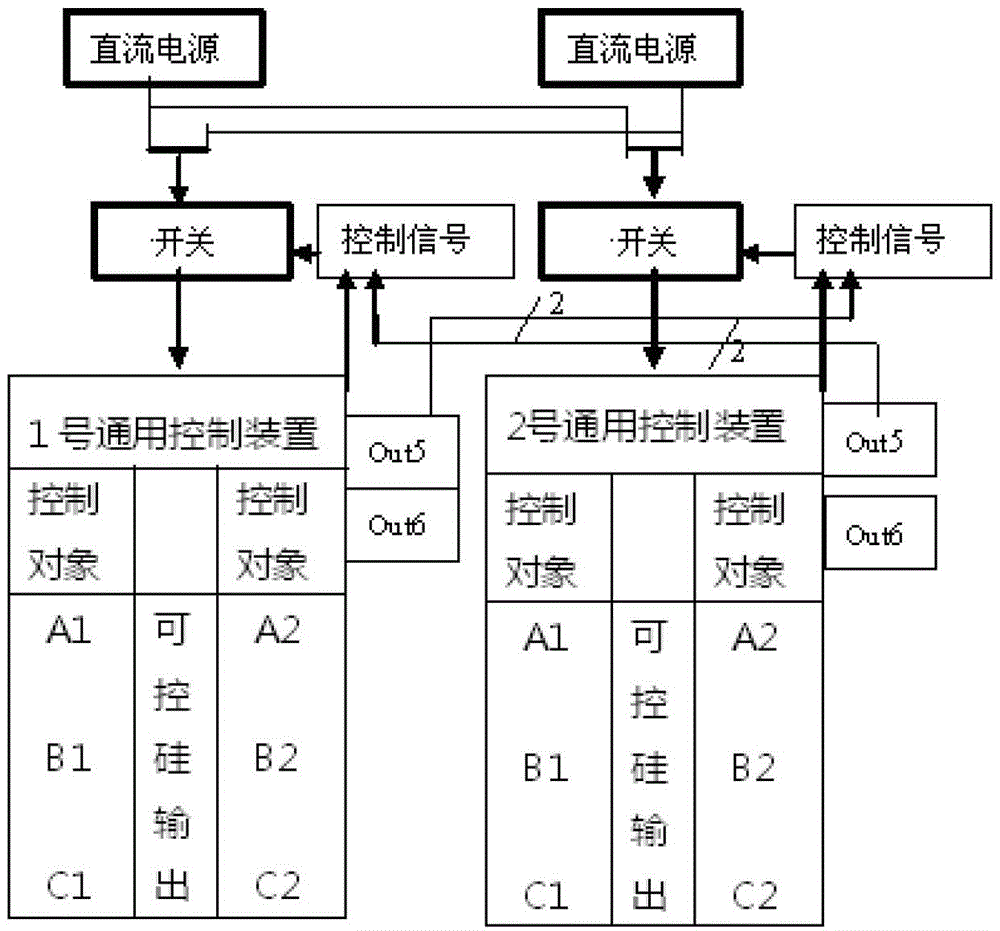

[0031] Example 1 ( figure 2 ):

[0032] The two control units are used to realize the mutual-aid two-way redundant control of the control objects A1-A2, B1-B2, and C1-C2; the DC power supplies in the two control units have two outputs: one of them is supplied to the substation. The corresponding DC power supply electronic switch input terminal is described, and the other output is connected in parallel with the input terminal of another DC power supply electronic switch. When a DC power supply fails, the DC power supply of the other control unit can be connected. Under the prerequisite of not increasing the number of DC power supply hardware, the extreme situation of simultaneous failure of two adjacent DC power supplies is eliminated, and the goal of online maintenance-free when the DC power supply fails is achieved.

[0033] The general control device in each control unit also outputs two sets of control signals, and each group of the same control signal is divided into two para...

Embodiment 2

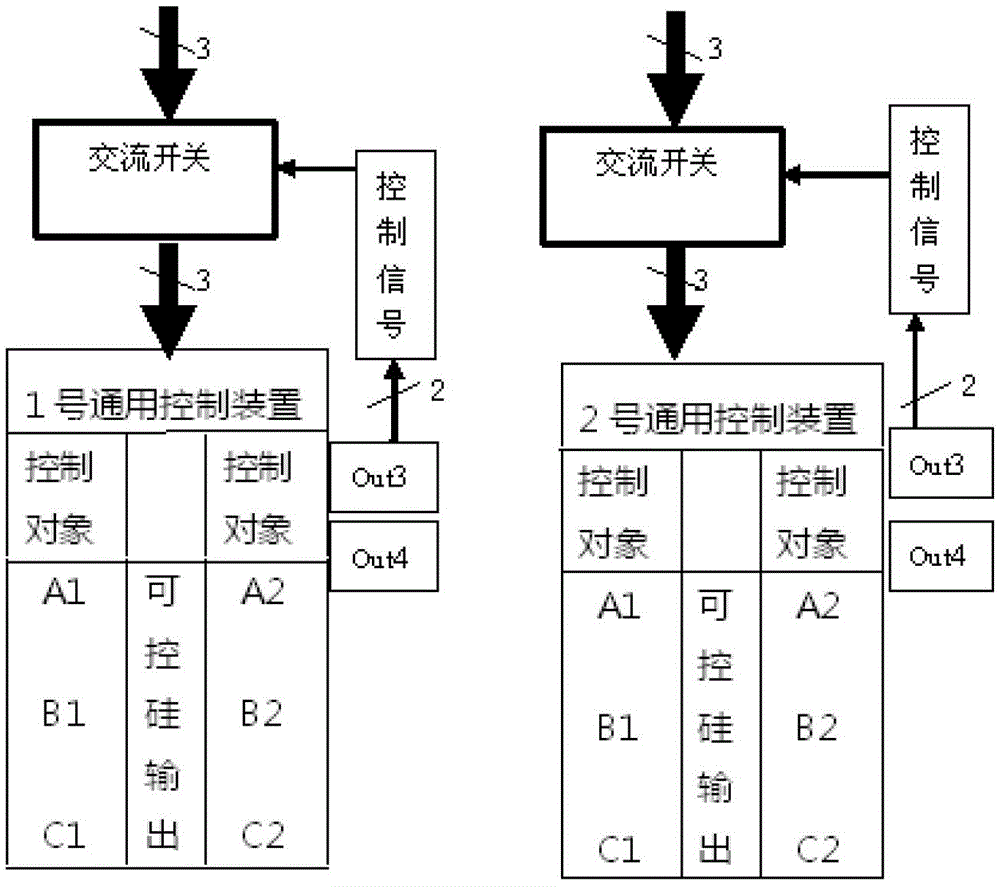

[0034] Example 2 ( image 3 ):

[0035] Two control units are used to realize the online redundant control of the control objects A1-A2, B1-B2 and C1-C2. The general control device in each control unit outputs (two parallel) control signals to the respective control units. The power electronic switch control signal input terminal. The function of this connection is to turn off the driving power when a certain non-contact element (SCR) fails, and to start the two controls while removing the faulty general control device The mutual assistance redundancy function between the units is to ensure that the non-contact element (silicon controlled thyristor) of the general control device can achieve the goal of online maintenance-free when a failure occurs. .

Embodiment 3

[0036] Example 3 ( Figure 4 ):

[0037] Two control units are used to realize the mutual-assisted two-phase redundant control of the control objects A1-A2, B1-B2 and C1-C2, and a general control device in each control unit outputs a set of signals (simultaneously The two ports are connected in parallel to the control signal input of the control unit. Their connection function is: according to the pre-appointed program control requirements, when a general control device detects the output of another general control device When the signal fails, it can be judged that the CPU of the other general control device has failed, and the faulty general control device is immediately eliminated, and the mutual assistance redundancy function between the two control units is activated to realize when the general control device fails The goal of online maintenance-free is achieved when the CPU fails.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com