Replaceable channel structure

A channel structure and channel technology are applied in the field of removable channel structures to achieve the effects of eliminating leakage, reducing costs, highlighting installation convenience and sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

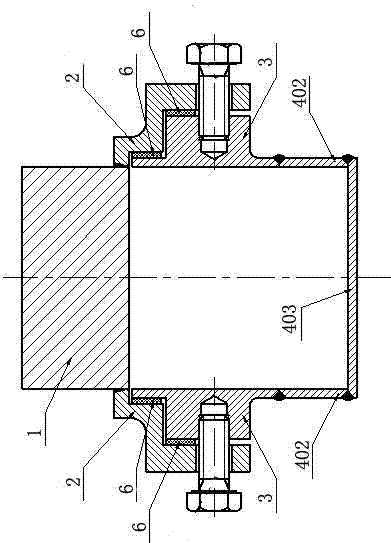

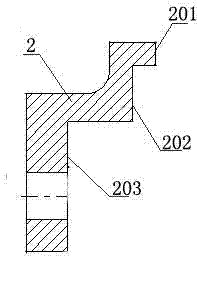

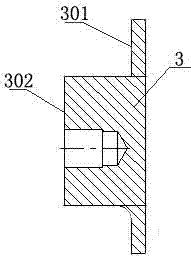

[0033] Such as figure 2 As shown, a removable channel structure mainly includes a metal body 1, a connecting piece 2, a sealing piece 3 and a lower sealing structure 4; the connecting piece 2 is symmetrically arranged on both sides of the metal body 1; the sealing piece 3 can pass through The disassembly connection is connected with the connecting part 2, the sealing part 2 is located under the metal body 1 in whole or in part; the lower sealing structure 4 is connected with the bottom of the sealing part 3; the connecting part 2, the sealing part 3 and the lower sealing part 4 are all along the metal body The direction of the axis of the body 1 extends to both ends of the metal body 1; the bottom surface of the metal body 1, the connecting piece 2, the sealing piece 3 and the lower sealing structure 4 jointly form a channel with openings at both ends.

[0034] When using this embodiment, the cooling liquid is passed through the channel to cool the metal body 1, so as to real...

Embodiment 2

[0039] In this embodiment, on the basis of the above-mentioned embodiments, the thermal conductivity of the materials constituting the connecting member 2 , the sealing member 3 and the lower sealing structure 4 is smaller than that of the material constituting the metal body 1 . In this embodiment, considering the weldability between the connecting piece 2 and the metal body 1, if the metal body 1 is made of copper, the connecting piece 2, the sealing piece 3 and the lower sealing structure 4 are preferably made of stainless steel. The thermal conductivity of copper is much higher than that of stainless steel, and the thermal conductivity of stainless steel is also low. Therefore, less heat is taken away through the connecting piece 2, the sealing piece 3 and the lower sealing structure 4. Only by letting the cooling water in the channel take away the heat of the metal body 1 can more accurate experiments be conducted on the influence of various geometric structure parameters ...

Embodiment 3

[0042] Such as figure 2 As shown, on the basis of the above embodiments, this embodiment further includes a gasket 6, which is compressed between the connecting part 2 and the sealing part 3, and the gasket 6 is made of a flexible sealing material. In this embodiment, the constituent material of the sealing gasket 6 is preferably silicon rubber, and other flexible sealing materials such as fluororubber, nitrile rubber, butyl rubber, etc. can also be used in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com