Leakage protection method and system of redox flow cell system as well as redox flow cell system

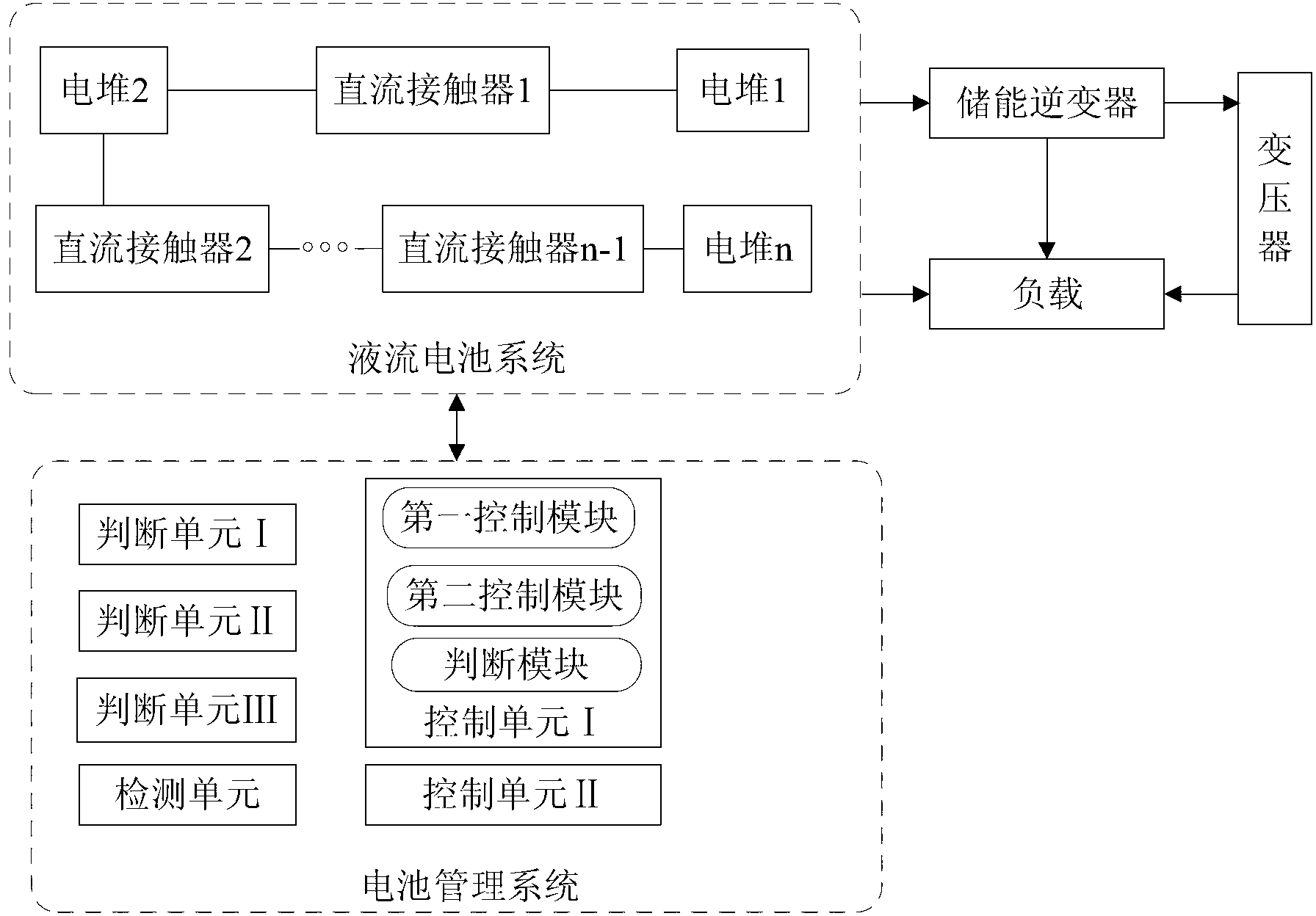

A flow battery, leakage protection technology, applied in fuel cell additives, regenerative fuel cells, etc., can solve the problems of heat treatment burden, damage to the stack, large size, etc., to simplify and facilitate post-maintenance, save hardware costs, and extend service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

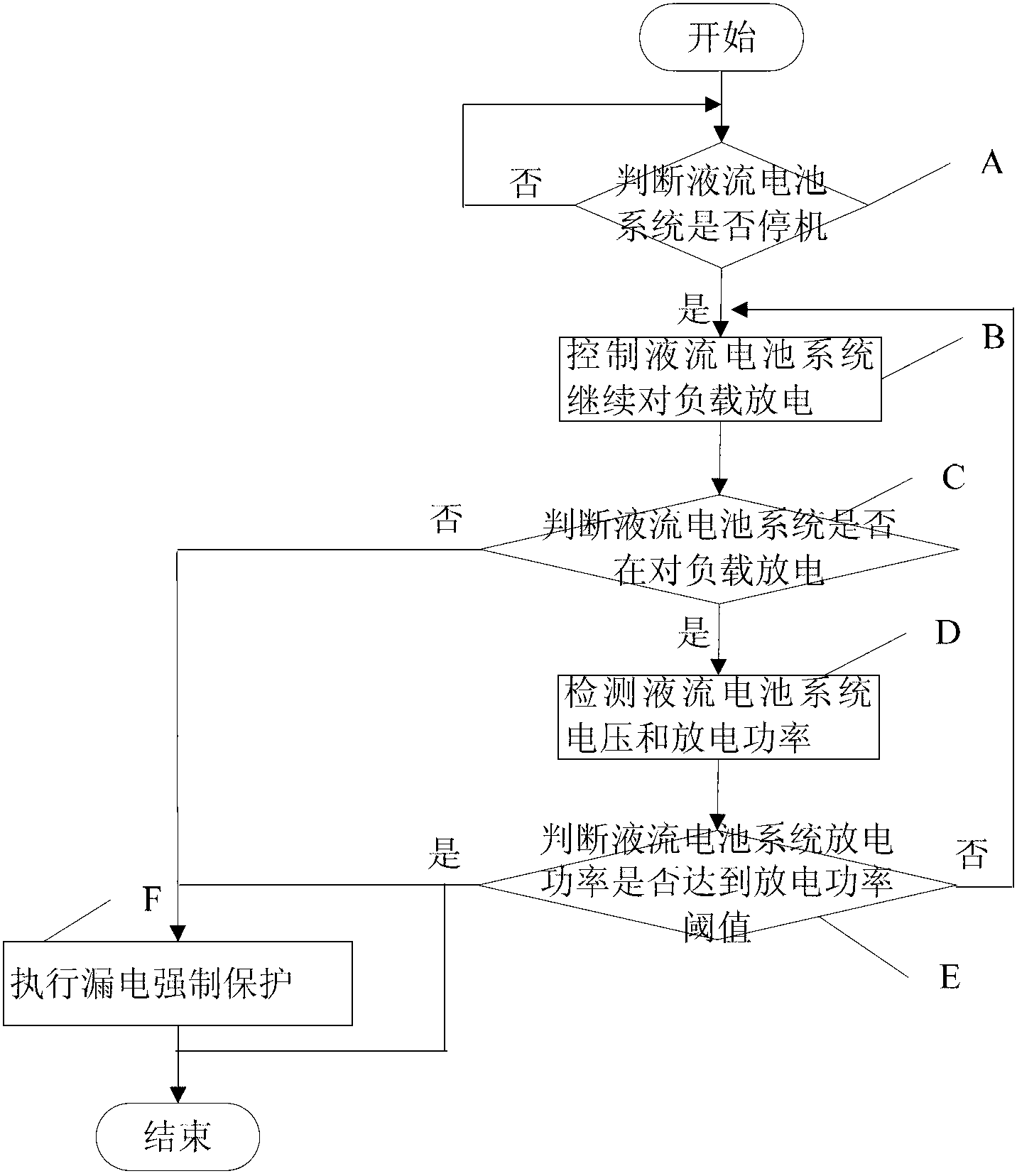

[0036] Such as figure 1 A leakage protection method for a liquid flow battery system includes the following steps:

[0037] A: After starting, judge whether the flow battery system is shut down, if yes, execute step B, otherwise return to start;

[0038] B: Control the flow battery system to continue discharging the load, and execute step C;

[0039] C: Determine whether the flow battery system is discharging the load, if yes, execute step D, otherwise execute step F;

[0040] D: Detect the voltage and discharge power of the flow battery system, and execute step E;

[0041] E: Determine whether the discharge power of the flow battery system reaches the discharge power threshold, if yes, execute step F or end, otherwise execute step B;

[0042] F: Execute mandatory leakage protection, end;

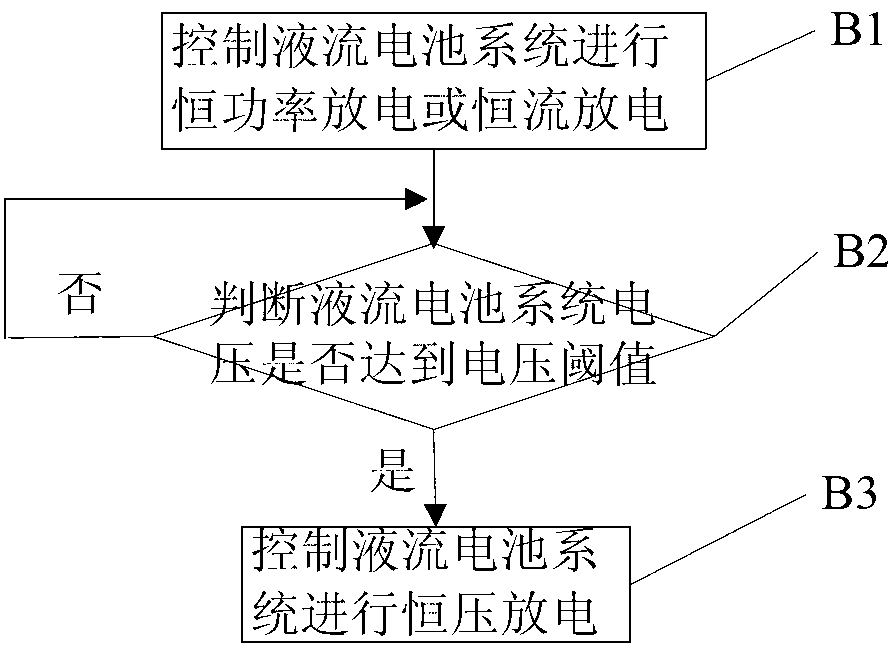

[0043] As preferred, such as figure 2 As shown, step B specifically includes the following steps:

[0044] B1: Control the flow battery system to perform constant power discharge or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com