UV laser exposure of housings and components of door drives and door closers

A door closer and housing technology, applied in the field of door operators or door closers, can solve problems such as disturbing noise, affecting the operation of door operators or door closers, etc., and achieve the effect of high strength and smooth surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

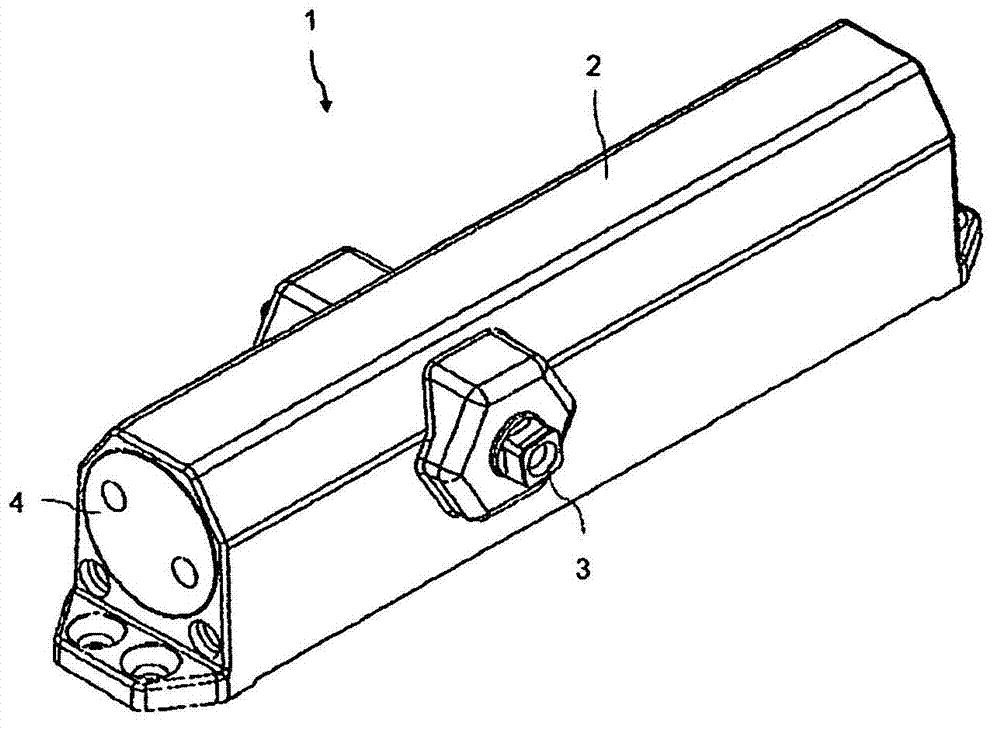

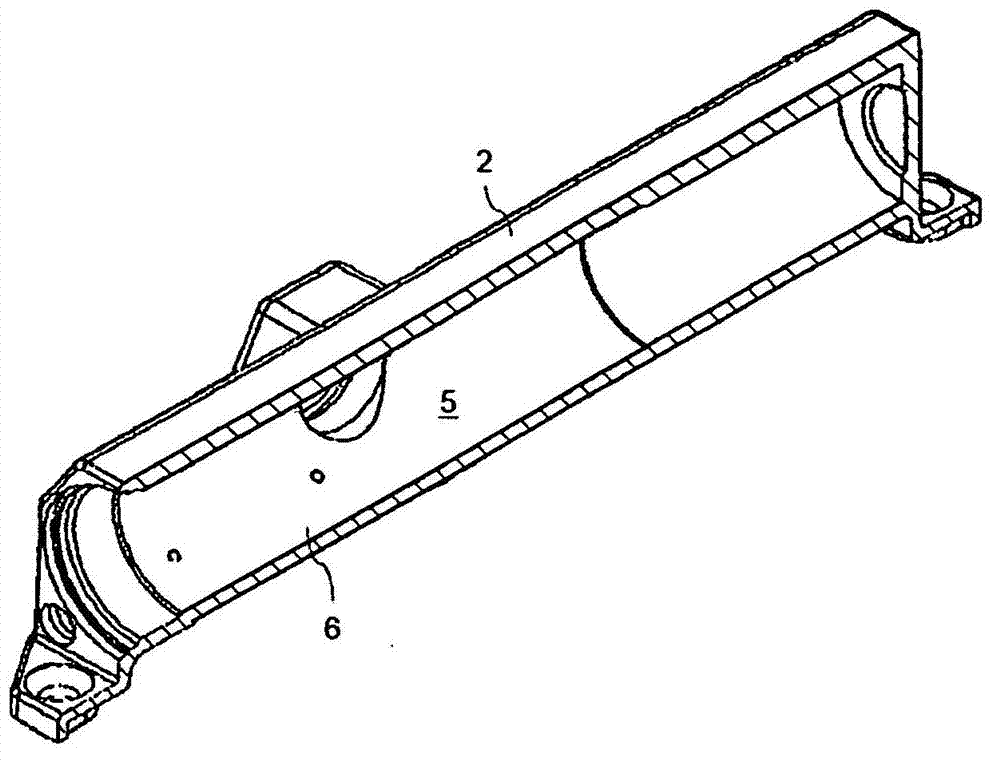

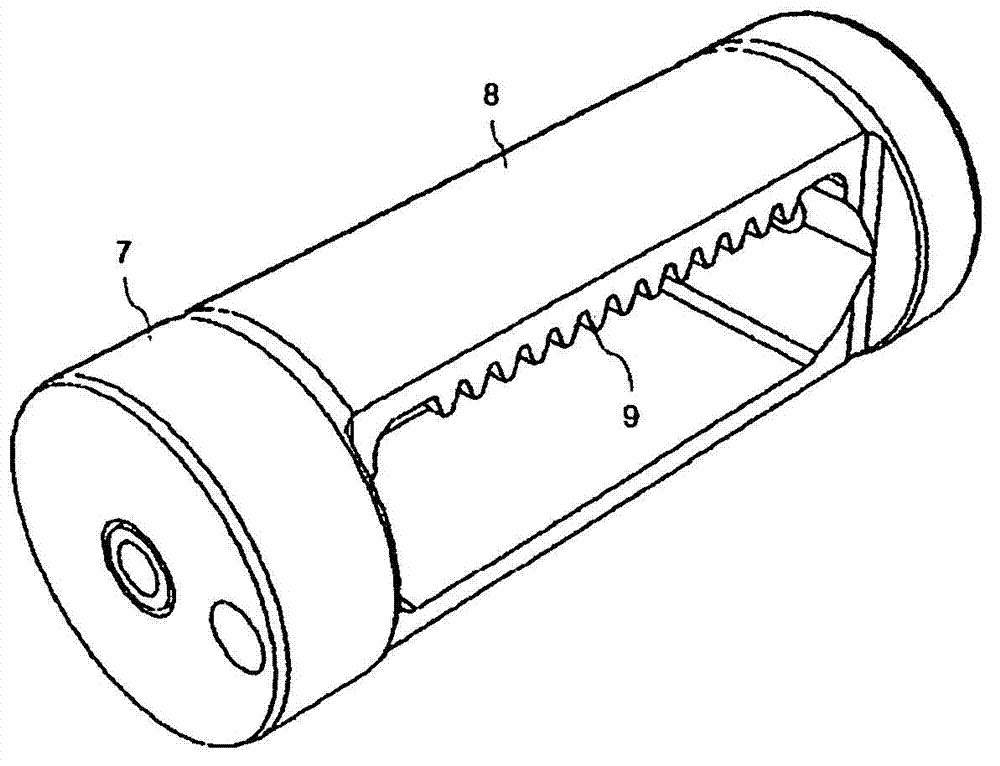

[0016] exist figure 1 A schematic perspective view of an embodiment of the inventive door closer 1 is shown in . In this case, the mechanical components of the door closer 1 are surrounded by a housing 2 . The interior of the housing 2 is accessible via a screwable end plate 4 . Inside the door closer 1 , the mechanical parts are actuated by means of the shaft 3 . The (not visible) piston 7 is held movably in the receiving unit 5 of the housing 2 and is driven via the shaft 3 . Due to the inventive treatment of the surface 8 of the piston 7 and the surface 6 of the receiving unit 5 respectively, the friction between the structural parts of the door closer 1 is reduced. Therefore, the high wear resistance and lifespan of the door closer 1 can be improved.

[0017] figure 2 shows the basis figure 1 A schematic perspective sectional view of the housing 2 of the inventive door closer 1 . Other structural components are not shown. The inner peripheral surface 6 of the rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com