Method and equipment for vulcanizing waste tires with low energy consumption and under normal pressure

A technology for waste tires and low energy consumption, which is applied in the field of waste tire treatment with low energy consumption and atmospheric pressure heat treatment. Reliable, secure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

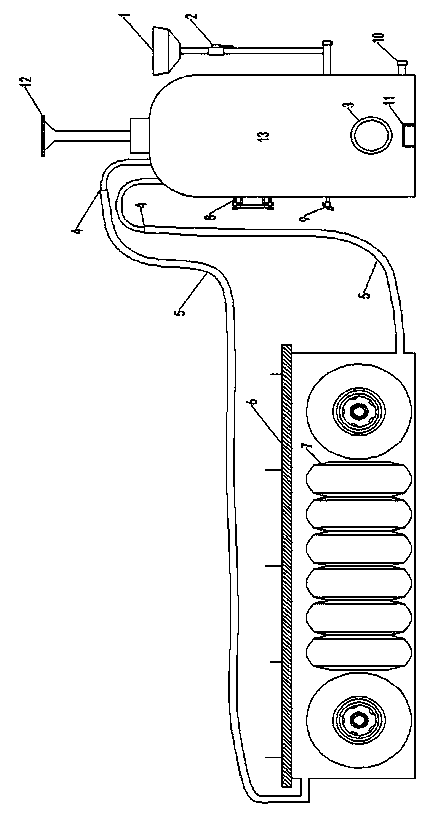

[0016] Such as figure 1 As shown, the equipment for treating waste tires with low energy consumption and atmospheric pressure heat repair of the present invention comprises: a water steam furnace 13, a sealing heat insulation layer 6 and a connecting polyethylene hose 5, and the water steam furnace is provided with a clean water inlet 1 and a water inlet Valve 2, furnace lower combustion chamber 3, furnace upper water vapor output port 4 and smoke exhaust port 12, through polyethylene hose 5, the water vapor output port 4 is connected with the sealed heat insulation layer 6, and the treated tire 7 is placed in a sealed In the insulation layer 6. There are two polyethylene hoses 5, and there are two water vapor outlets, which are respectively connected with the polyethylene hoses 5. One polyethylene hose 5 is connected to the upper left side of the sealed heat insulation layer 6, and the other polyethylene soft The pipe 5 is connected to the lower part of the side of the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com