Processing technology for improving winch guide rope wheel split type shaft sleeve whole circle zero clearance

A processing technology and a technology of a rope guide wheel, which is applied in the field of hoisting winch guide wheel split type shaft sleeve full circle zero clearance processing technology, to achieve the effect of flexible operation, reasonable steps, and uniform assembly clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

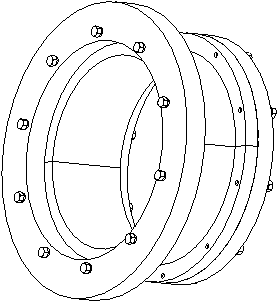

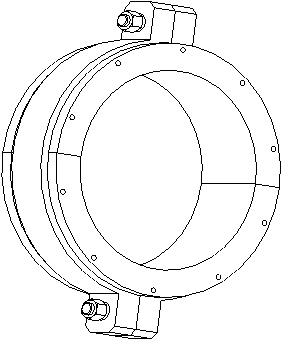

[0029] In order to improve the machining accuracy of the inner hole, the wheel groove and the outer circle of the split shaft sleeve, the invention designs the zero-clearance processing technology and tooling of the split shaft sleeve, which ensures the uniform assembly clearance between the split shaft sleeve and the shaft diameter requirements.

[0030] The process route and method designed and formulated are as follows:

[0031] (1) Rough machining is carried out on the shaft sleeve blank first, and a finishing allowance of 3 mm is reserved for each side of the inner hole, wheel groove and each end face;

[0032] (2) Divide the rough-machined bushing in half by wire cutting, and carry out group identification on the split bushing;

[0033] (3) Carry out milling finishing on the split surface of the shaft sleeve to ensure that the split surface is in the same plane (processing amount is 0.3mm);

[0034] (4) According to the group identification of the bushing, assemble it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com