Antifouling polishing device for ceramic equipment

A polishing device and anti-fouling technology, which is applied in the direction of ceramic forming machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems that cannot be popularized and applied, poor sealing performance of gear mechanisms, and high maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

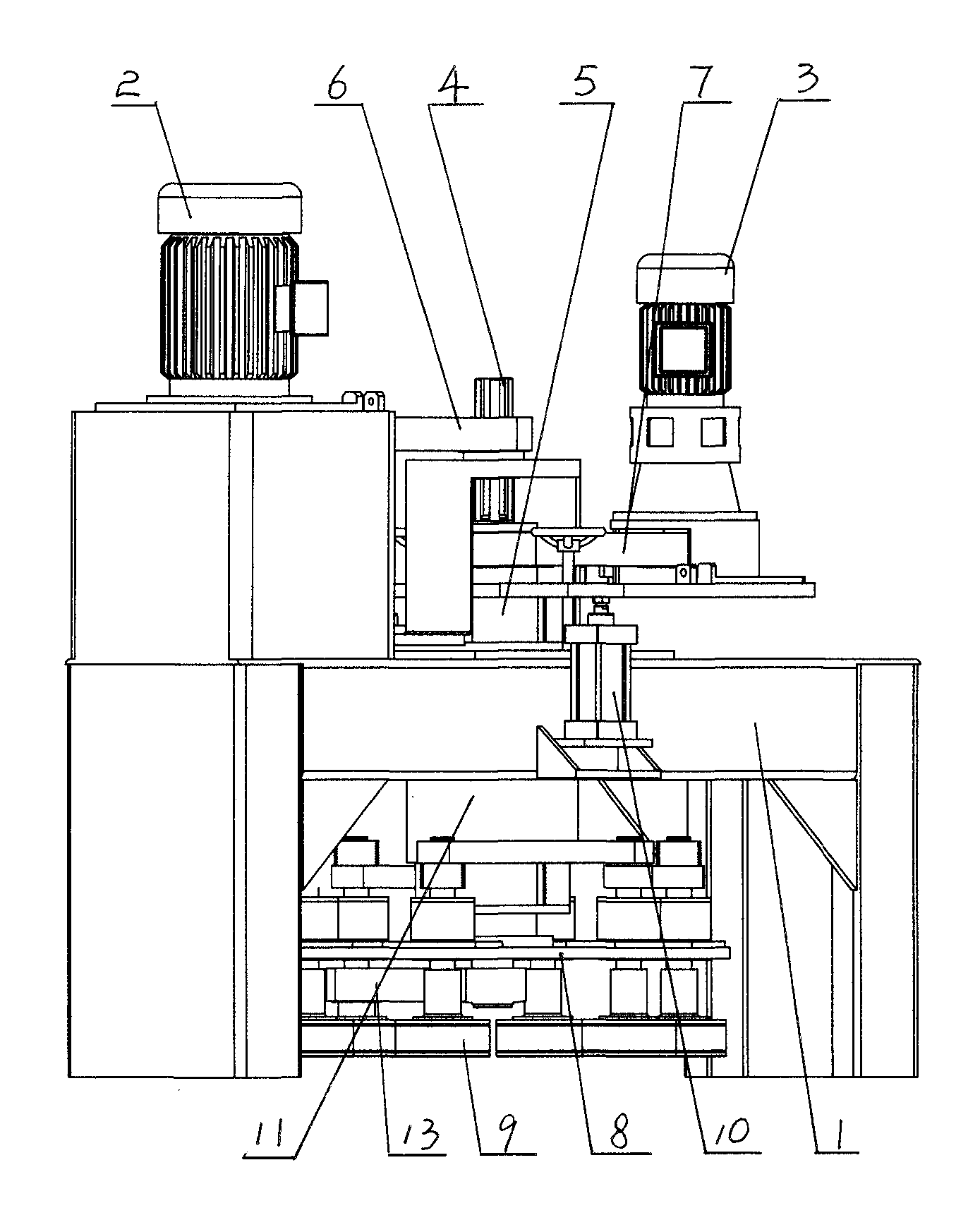

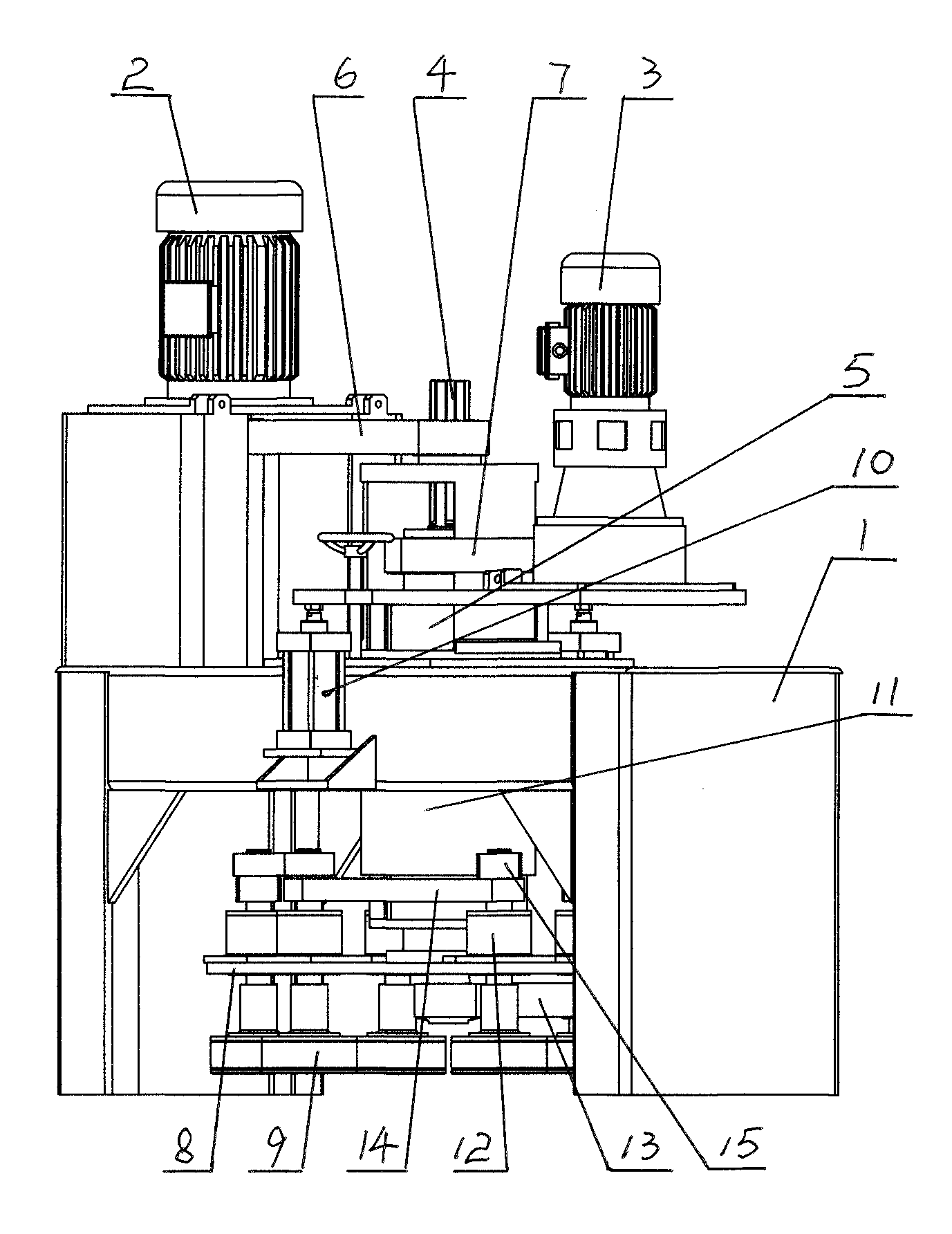

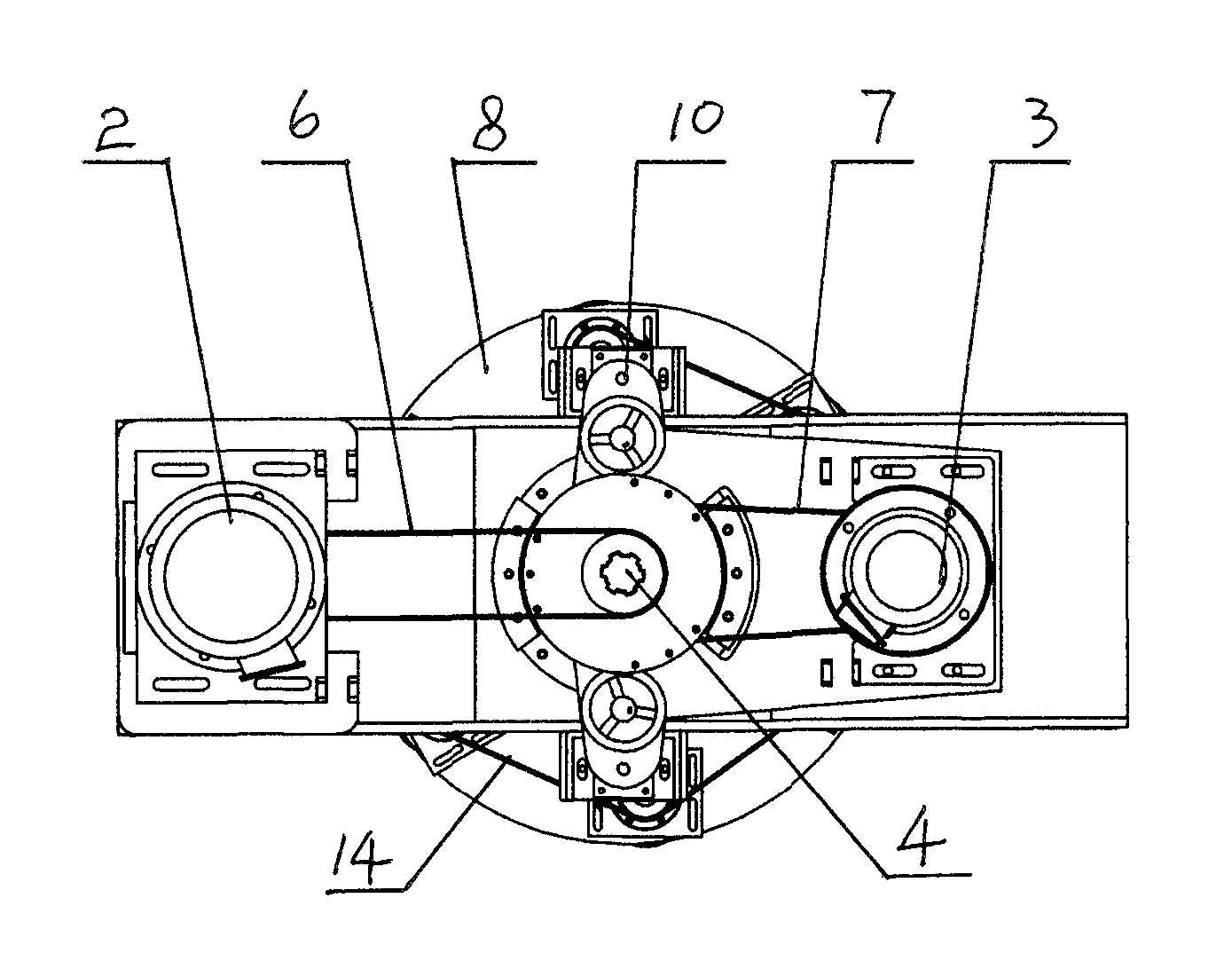

[0012] see Figure 1-Figure 5 , the anti-fouling polishing device for ceramic equipment in this embodiment, the main body is a frame 1, the main motor 2 and the auxiliary motor 3 are respectively fixed on the frame 1, and the rotating shaft is a concentric structure formed by the main shaft 4 and the auxiliary shaft 5 respectively. Shafts, the main shaft 4 is inside and the auxiliary shaft 5 is outside, and each rotates independently of each other. The main motor 2 drives the main shaft 4 through the first belt and the pulley 6, and the auxiliary motor 3 drives the auxiliary shaft 5 through the second belt and the pulley 7, so that the main shaft 4 and the auxiliary shaft 5 can rotate independently at different speeds. Both the main shaft 4 and the auxiliary shaft 5 pass through the frame 1 and are located under the frame 1. Under the frame 1, the auxiliary shaft 5 is fixedly connected with the turntable 8 through the bushing 11. Therefore, the turntable 8 rotates with the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com