Pass-on device applied among several assembly lines

A transfer device, assembly line technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of waste of manpower, material resources, low production efficiency, etc., to optimize production, improve production efficiency, and avoid the consumption of human and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

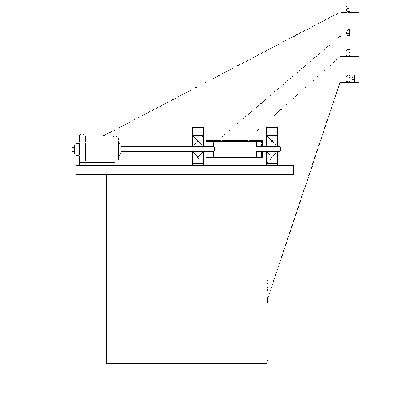

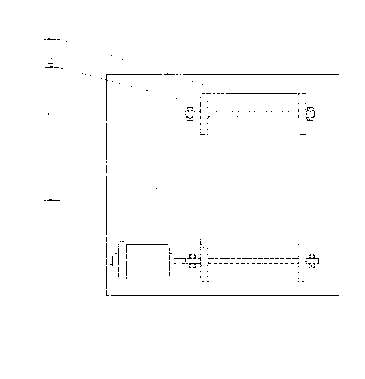

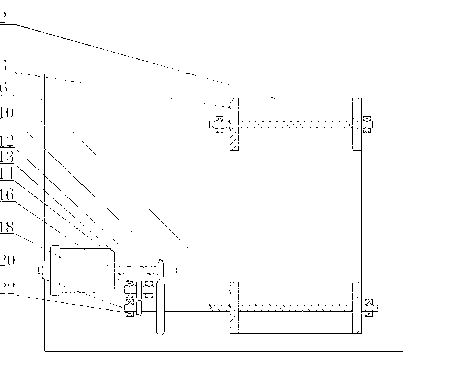

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 and figure 2 As shown, in the first embodiment of the present invention, including workbench 6 and the lifting device 24 that can adjust the height of workbench 6, two groups of four transmission wheels are arranged on the top of workbench 6, and each group of transmission wheels 4 passes through the conveyor belt. 2, the workbench 6 is also provided with a first motor 8 to drive one of the transmission wheels 4 to rotate, and the first motor 8 can rotate forward or reversely. During work, the first motor 8 on the workbench 6 drives the transmission wheel to rotate, drives the conveyor belt 2 to move, and transports the workpiece on an assembly line to the top of the conveyor belt 2, and then stops moving. The production line is raised or lowered to another production line, and the first motor 8 drives the conveyor belt 2 to run in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com