Method for making adhesive film

A manufacturing method and technology for bonding films, which are applied in the direction of film/sheet-like adhesives, adhesives, etc., can solve the problems of reduced workability, inability to stabilize co-extrusion molding, and inability to increase the mixing ratio of tackifying resin, etc. Stable quality and good forming workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

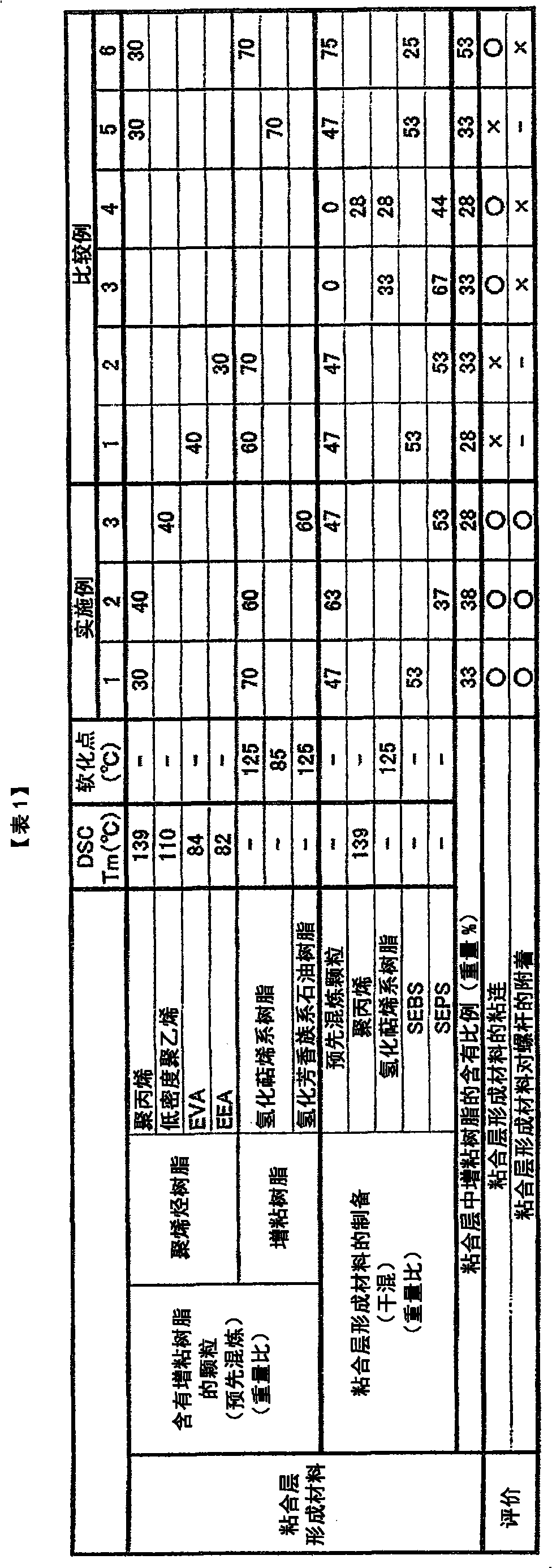

Embodiment 1

[0059]As the thermoplastic resin in the substrate layer forming material, low-density polyethylene (manufactured by Nippon Polyethylene Co., Ltd., NOVATEC LD LF547) was used, and as the polyolefin resin in the adhesive layer forming material, polypropylene (Japan POLYCHEM ( Co., Ltd., product name "NOVATEC PPFX3", melting temperature 139°C, MFR8.0 (according to JIS-K6921-2)), as the thermoplastic elastomer in the adhesive layer forming material, styrene-butadiene- Hydrogenated styrene block copolymer (SEBS, manufactured by Shell Chemical Co., Ltd., trade name "KRATON G1657"), as the tackifier resin in the adhesive layer forming material, hydrogenated terpene-based resin (manufactured by Yasuhara Chemical Co., Ltd., trade name "Clearon P125").

[0060] First, the polyolefin-based resin and the hydrogenated terpene-based resin were melt-mixed in accordance with the compounding ratio shown in Table 1 to prepare pre-kneaded pellets. Then, the pre-kneaded granules and SEBS were dr...

Embodiment 2

[0062] As the thermoplastic elastomer in the adhesive layer forming material, a hydrogenated product of styrene-isoprene-styrene block copolymer (SEPS, manufactured by Kuraray Co., Ltd., trade name "Septon 2043") was used instead of SEBS, according to the table In addition, polypropylene and hydrogenated terpene-based resin were melt-mixed at the compounding ratio shown in Table 1 to prepare pre-kneaded pellets, and the pre-kneaded pellets and SEPS were dry-blended at the compounding ratio shown in Table 1. Example 1 was carried out similarly, and the adhesive film (2) which has a base material layer (thickness 100 micrometers) and an adhesive layer (thickness 15 micrometers) was manufactured.

Embodiment 3

[0064] As the polyolefin-based resin in the adhesive layer forming material, low-density polyethylene (melting temperature 110°C, MFR2.0 (according to JIS-K6922-2)) is used instead of polypropylene, and as the thermoplastic elastic in the adhesive layer forming material body, using hydrogenated styrene-isoprene-styrene block copolymer (SEPS, manufactured by Kuraray Corporation, trade name "Septon 2043") instead of SEBS as the tackifier resin in the adhesive layer forming material, Using hydrogenated aromatic petroleum resin (manufactured by Arakawa Chemical Industry Co., Ltd., trade name "ARCON P-125") instead of hydrogenated terpene resin, low-density polyethylene and hydrogenated aromatic Petroleum resin was melt-mixed to make pre-kneaded granules, and the pre-kneaded granules and SEPS were dry-blended according to the compounding ratio shown in Table 1. Except this, it was carried out in the same manner as in Example 1, and a product with a base material layer ( Adhesive fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com