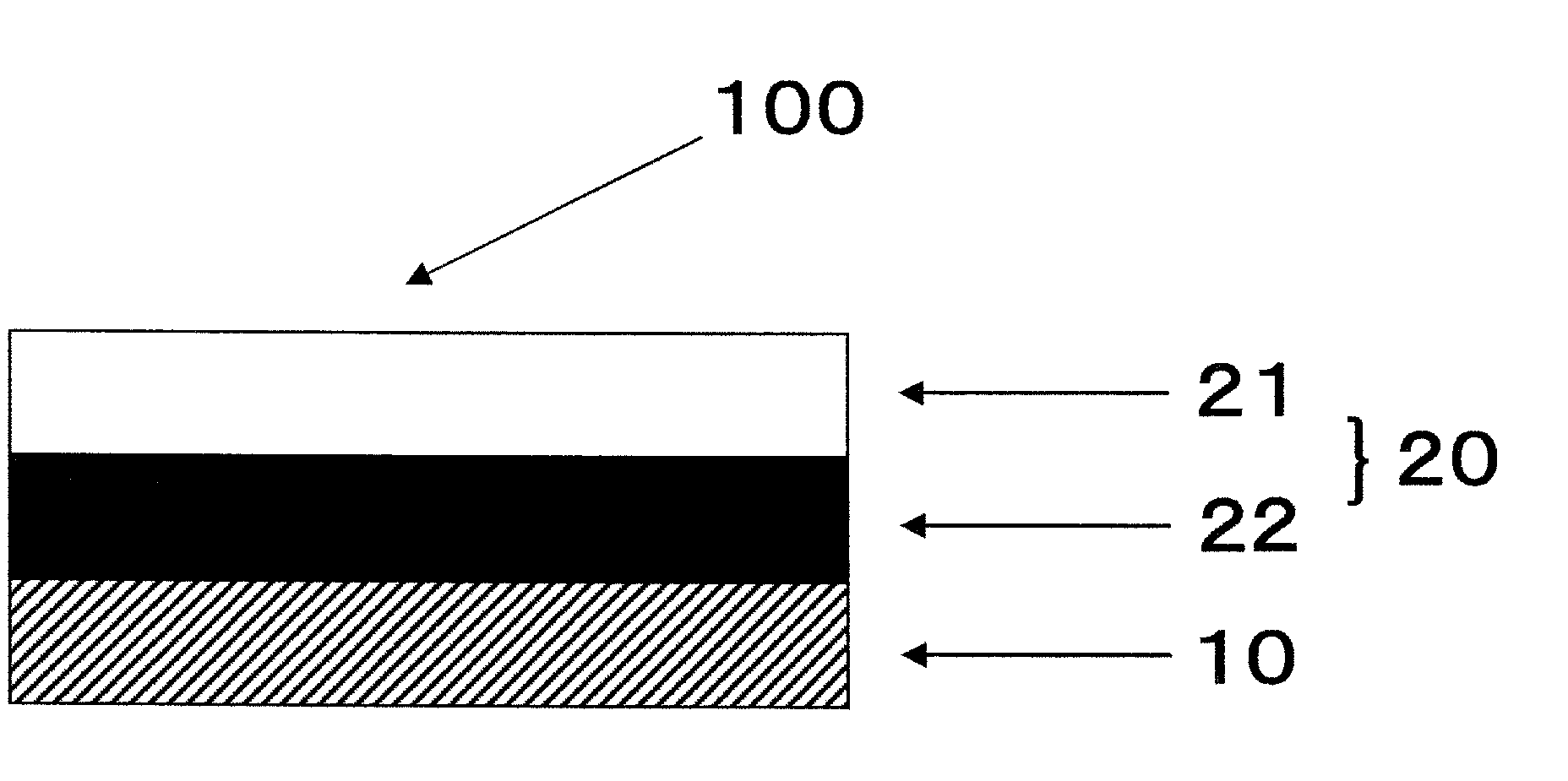

Surface protection sheet

A technology of protective sheet and substrate layer, applied in the direction of film/sheet-like adhesives, adhesives, etc., can solve the problems of increased adhesive force, high adhesive force, insufficient weather resistance of the surface protective sheet, etc. The effect of suppressing the increase in adhesive strength and sufficient weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

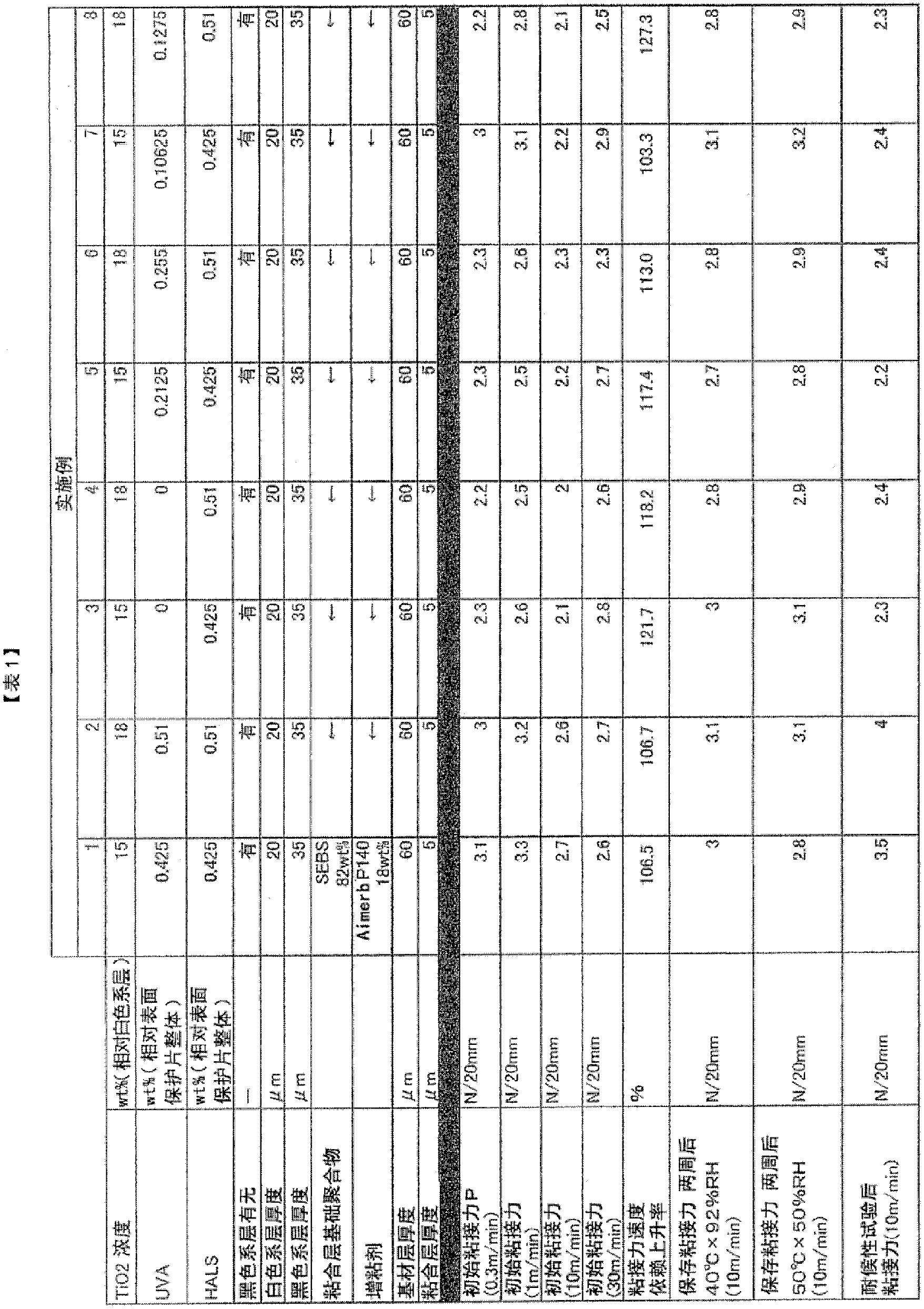

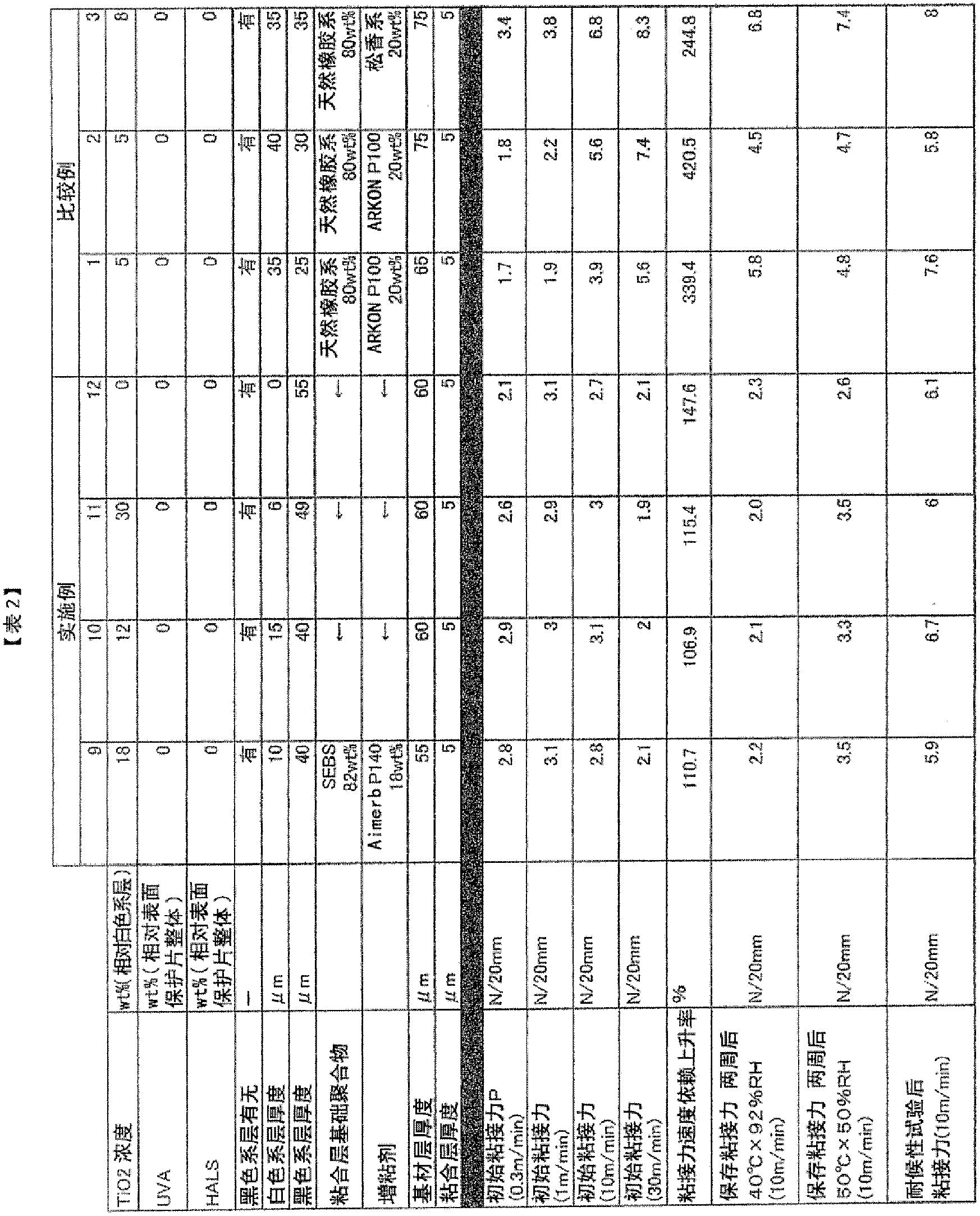

[0118] Compared to low-density polyethylene (manufactured by Tosoh, trade name: Petrothene 186R, density = 0.924 g / cm 3 ), white pigment (titanium oxide, manufactured by Dupont, trade name: Ti-Pure R103), ultraviolet absorber (UVA, manufactured by BASF, trade name: Tinuvin326), hindered amine light stabilizer (HALS , manufactured by BASF, trade name: Tinuvin 783), and a white-colored layer-forming material was obtained.

[0119] Next, with respect to the low-density polyethylene (manufactured by Tosoh, trade name: Petrothene186R, density=0.924g / cm 3 ) 85% by weight and linear low-density polyethylene (manufactured by Sumitomo Chemical, trade name: ExcellenFX FX307, density=0.890g / cm 3 ) 10% by weight of a resin mixture, and 5% by weight of carbon black MB (manufactured by Sumika Color, trade name: Black SPEMB-865, carbon content 20%) was blended to obtain a black layer forming material.

[0120] Furthermore, 82% by weight of SEBS (hydrogenated SEBS, styrene content = 15% by ...

Embodiment 2

[0124]As shown in Table 1, the composition of the white-colored layer-forming material was changed, except that, it was carried out in the same manner as in Example 1 to obtain a surface protection sheet (2) ( Thickness: white color layer / black color layer / adhesive layer=20μm / 35μm / 5μm).

[0125] The results are shown in Table 1.

Embodiment 3

[0127] As shown in Table 1, the compounding of the white-colored layer forming material was changed, except that, it was carried out in the same manner as in Example 1 to obtain a surface protection sheet (3) of a three-layer structure (white-colored layer / black-colored layer / adhesive layer). Thickness: white color layer / black color layer / adhesive layer=20μm / 35μm / 5μm).

[0128] The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com