Adhesive tape

A technology of adhesive tape and adhesive layer, applied in the direction of adhesive types, ester copolymer adhesives, polymer adhesive additives, etc., can solve the problem of increased adhesive force, adhesive residue on adherends, There are no problems such as no effect, and the effects of suppressing residual glue, suppressing the increase of adhesive force, and easy handling are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] Hereinafter, the present invention will be specifically described by way of examples, but the present invention is not limited by these examples. Unless otherwise specified, parts mean parts by weight, and % means % by weight. In addition, the amount of the reagent supplied in the form of a solution is represented by the amount of solid content remaining after volatilizing the solution (solid content conversion amount).

[0124]

[0125] An indentation test was performed on the surface of the pressure-sensitive adhesive layer under the following conditions, and the indentation hardness and indentation modulus of elasticity were determined from the results.

[0126] (Measurement device and measurement conditions)

[0127] Device: Tribo Indenter manufactured by Hysitron Inc.

[0128] Indenter used: Berkovich (triangular cone type)

[0129] Measurement method: single indentation measurement

[0130] Measuring temperature: 25°C, 100°C

[0131] Indentation depth setti...

manufacture example 1

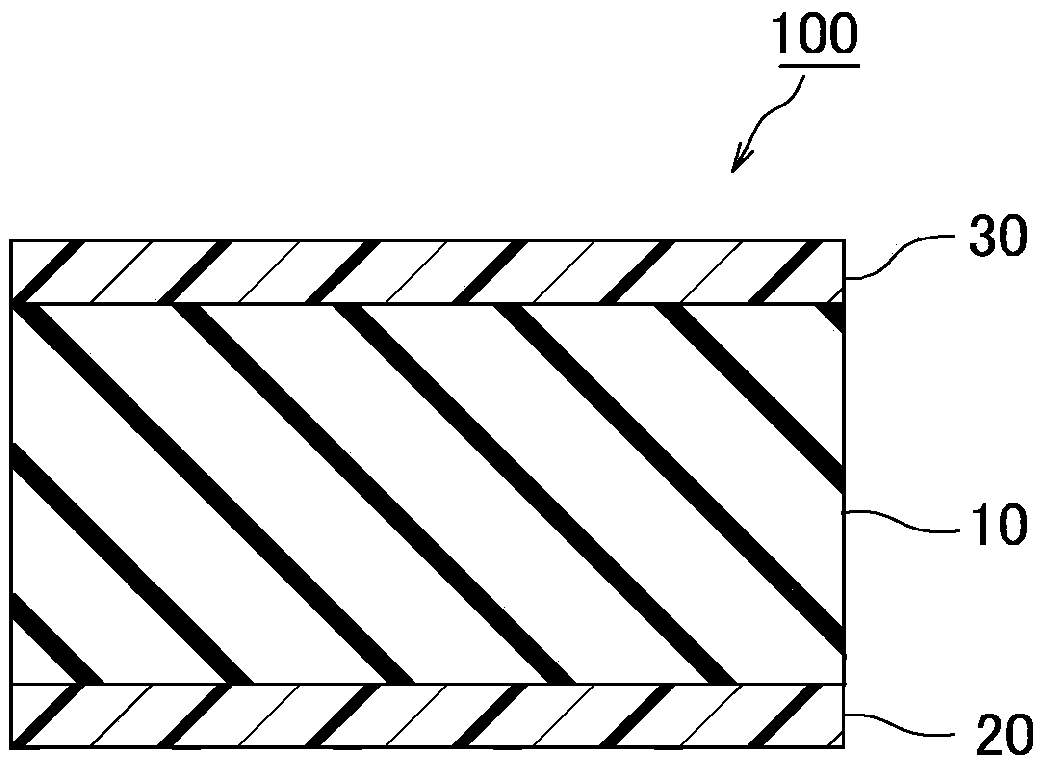

[0167] [Manufacturing example 1]: Manufacture of base material

[0168] Manufactured by calendaring method Contains 27 parts by weight of DOP plasticizer (bis(2-ethylhexyl phthalate), manufactured by J-PLUS Co., Ltd.) with respect to 100 parts by weight of polyvinyl chloride with a degree of polymerization P=1050 soft polyvinyl chloride film. The thickness of the obtained flexible polyvinyl chloride film was 70 μm, the elastic modulus (MD) measured according to JIS-K-7127 (1999) was 250 MPa, and the maximum elongation measured according to JIS-K-7127 (1999) (MD) is 400%. In addition, the arithmetic mean surface roughness Ra immediately after production was 0.1 μm.

Embodiment 1

[0170] (non-adhesive layer)

[0171] 60 parts by weight of polysiloxane resin (KS-723A, manufactured by Shin-Etsu Chemical Industry), 40 parts by weight of polysiloxane resin (KS-723B, manufactured by Shin-Etsu Chemical Industry), an acrylic copolymer (methyl methacrylate ( MMA) / butyl acrylate (BA) / hydroxyethyl acrylate (HEA)=70 / 30 / 10) 50 parts by weight, tin-based catalyst (Cat-PS3, manufactured by Shin-Etsu Chemical Co., Ltd.) 10 parts by weight were mixed in a solution state, A mixed solution (1) was obtained. The mixing ratio of the polysiloxane and the (meth)acrylic polymer in the mixed solution (1) was polysiloxane:(meth)acrylic polymer=2:1 by weight ratio.

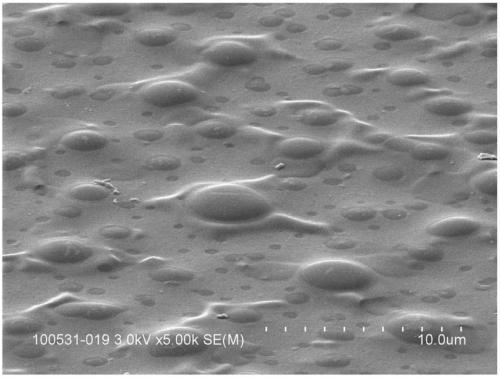

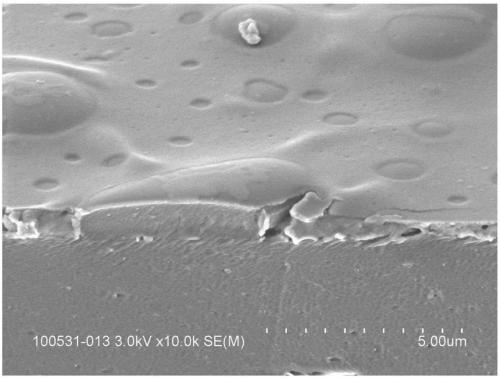

[0172] The above-mentioned mixed solution (1) was coated on one side of the soft polyvinyl chloride film obtained in Production Example 1, and dried to form a non-adhesive layer (1) having a thickness of 1.0 μm and an arithmetic mean surface roughness Ra=0.5 μm.

[0173] In addition, when the non-adhesive layer (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com