Adhesive composition for surface protection film and surface protection film

A surface protection film and adhesive technology, applied in the direction of film/sheet adhesive, adhesive type, ester copolymer adhesive, etc., can solve the problem of insufficient flexibility of the adhesive layer, sticky Solve the problems of increased resultant force and poor wettability of the adherend, and achieve the effect of inhibiting the increase of adhesive force, reducing pollution and metal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

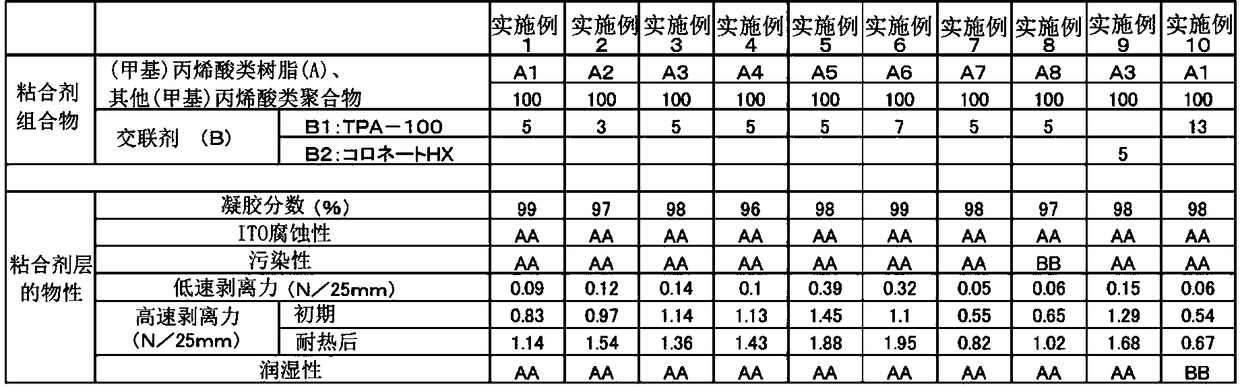

[0132] Hereinafter, the present invention will be described more specifically based on examples, but the present invention is not limited to these examples. In descriptions of the following Examples and the like, "parts" means "parts by mass" unless otherwise specified.

[0133] [GPC]

[0134] The weight average molecular weight (Mw) and the number average molecular weight (Mn) of the (meth)acrylic resin (A) were calculated|required by the gel permeation chromatography (GPC) method under the following conditions.

[0135] ・Measuring device: HLC-8320GPC (manufactured by Tosoh Corporation)

[0136] ・The composition of the GPC column: the following 4 columns (all manufactured by Tosoh Co., Ltd.)

[0137] (1) TSKgel HxL-H (guard column)

[0138] (2) TSKgel GMHxL

[0139] (3) TSKgel GMHxL

[0140] (4)TSKgel G2500HxL

[0141] ·Flow rate: 1.0ml / min

[0142] ·Column temperature: 40℃

[0143] ·Sample concentration: 1.5% (w / v) (diluted with tetrahydrofuran)

[0144] ·Mobile p...

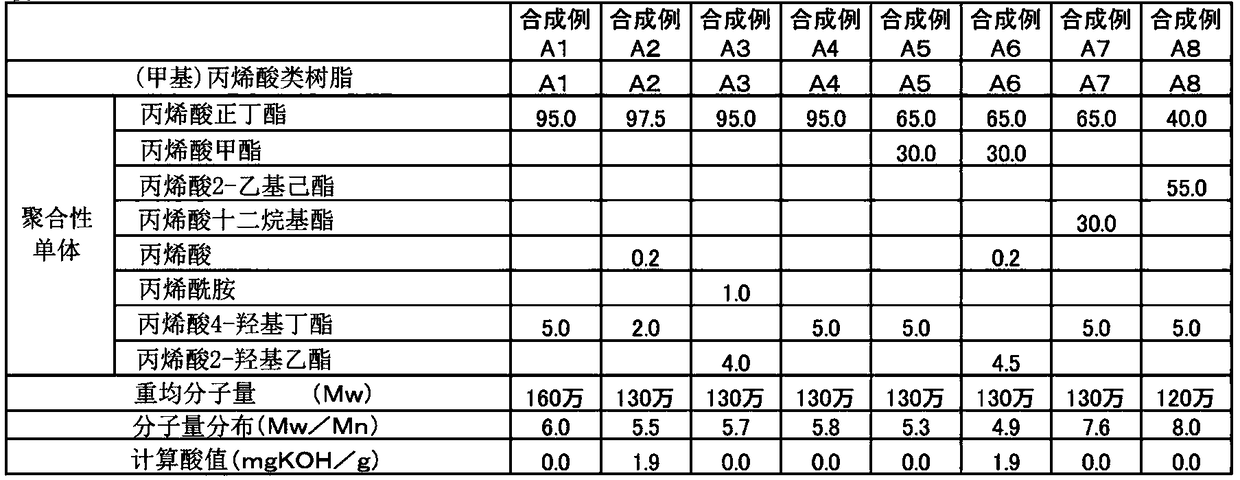

Synthetic example A1

[0149] Add 95.0 parts of n-butyl acrylate, 5.0 parts of 4-hydroxybutyl acrylate, and 100 parts of ethyl acetate solvent to a reaction device equipped with a stirrer, a reflux cooler, a thermometer, and a nitrogen gas introduction tube, and raise the temperature to 80°C while introducing nitrogen gas . Then, 0.1 part of 2,2'-azobisisobutyronitrile was added, and the polymerization reaction was performed at 80 degreeC for 6 hours in nitrogen atmosphere. After completion of the reaction, it was diluted with ethyl acetate to prepare a polymer solution having a solid content concentration of 20% by mass. Mw of the obtained (meth)acrylic resin A1 was 1.6 million, and Mw / Mn was 6.0. The calculated acid value is 0.

Synthetic example A2

[0151] Except for blending polymerizable monomers and changing the blending amount of ethyl acetate solvent to 115 parts by mass as described in Table 1-1, the polymerization reaction and the preparation of the polymer solution were carried out in the same manner as in Synthesis Example A1 to obtain A polymer solution containing (meth)acrylic resin A2 with a solid content concentration of 20% by mass. The results are shown in Table 1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com