Ignition device of fire-spraying opening of gasifier and treatment process thereof

A technology of ignition device and crater, applied in the field of gasifier, can solve the problems of inability to ignite, high-voltage electric spark failure, incomplete primary treatment, etc., and achieve the effect of eliminating blue smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

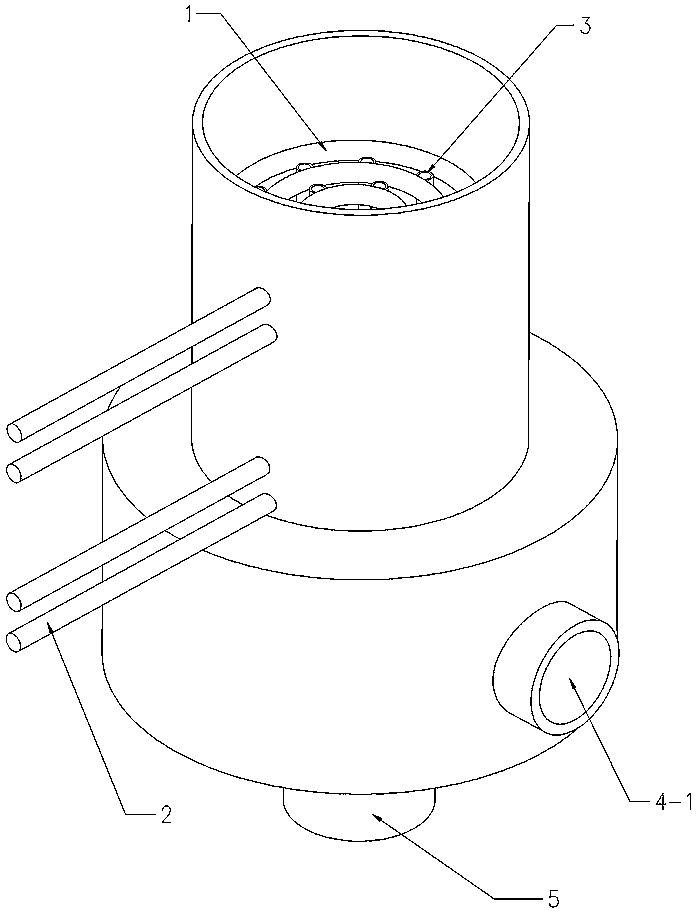

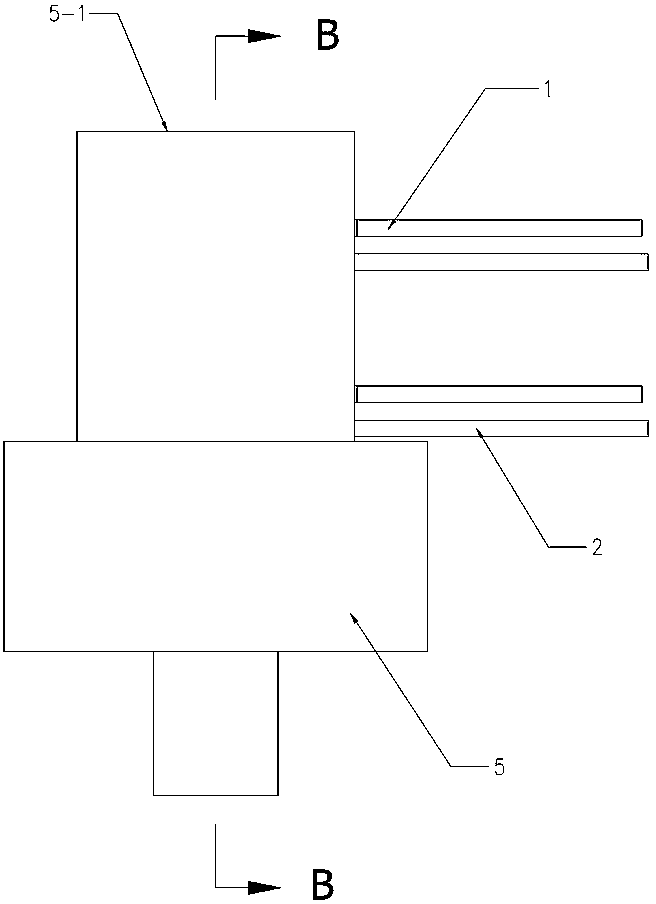

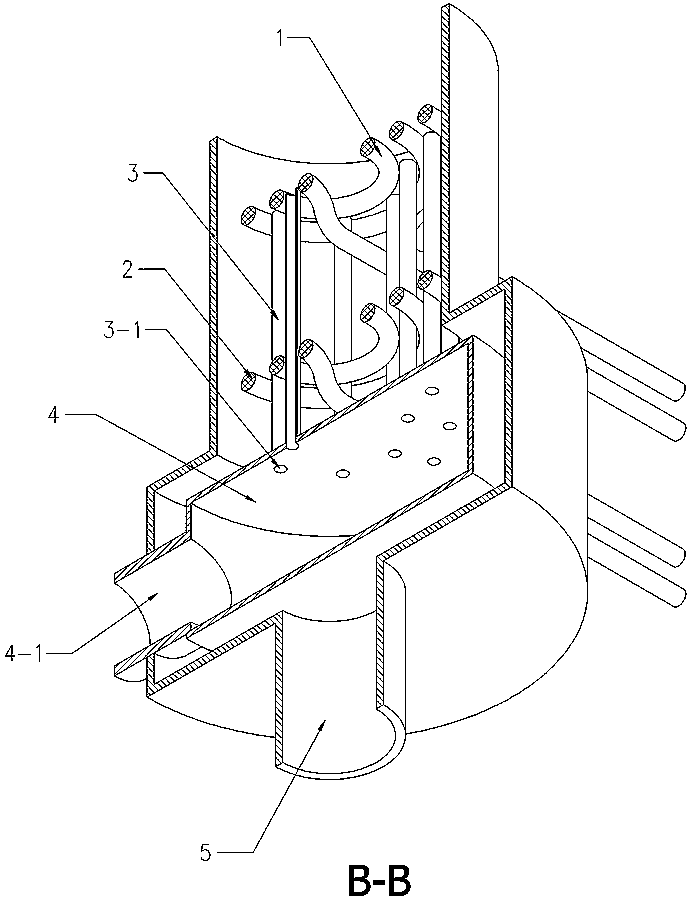

[0038] The structure of the ignition device of the gasifier vent is as follows: figure 1 - Figure 5 As shown, it includes: ignition electric heating pipe 1, heating electric heating pipe 2, small air supply pipe 3, air chamber 4, gas pipe 5, gas transmission pipe 6, time relay; multiple time relays are respectively connected with ignition electric heating pipe 1 and heating electric heating pipe 2 and fan electrical connections;

[0039] The gas pipe 5 is a gas pipeline with two ends and a cylindrical enlarged gas pipeline in the middle. The enlarged cylindrical part accommodates the air chamber 4, and the air inlet pipe 4-1 with the air chamber passes through the cylinder wall. Leading to the fan, the passage is welded and sealed; the gas pipe 5 near the crater accommodates two electric heating pipes and multiple small air supply pipes 3, and the power line of the electric heating pipe passes through the wall of the gas pipe 5 and is electrically connected to the relay. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com