Biomass gas generating equipment for firing ceramics

A technology for biomass gas and generating equipment, applied in the manufacture of combustible gas and petroleum industry, etc., can solve the problems of high production cost of ceramic products, reduced market competitiveness of enterprises, unstable temperature, etc., to enhance safety, reduce The effect of labor intensity, raw material combustion and gasification stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

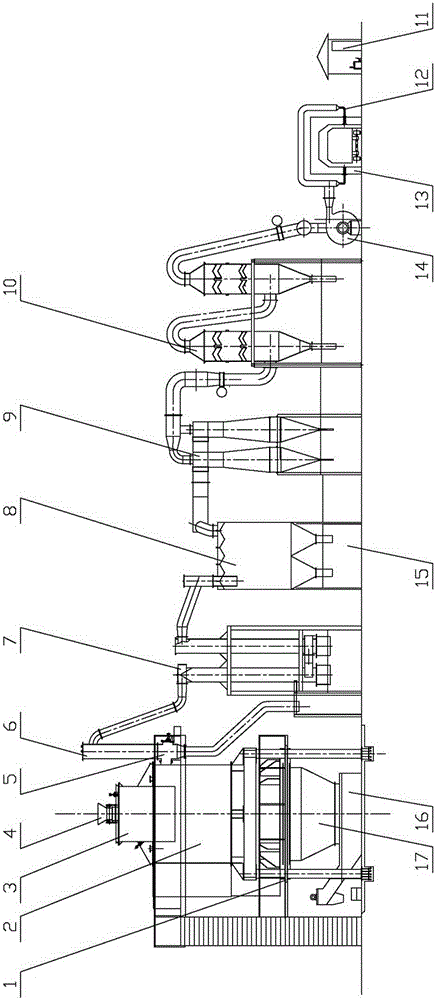

[0023] The gist of the present invention is to overcome the deficiencies of the prior art, and provide a biomass gas generating device for firing ceramics, including a gas generator and a purification system. The furnace body of the gas generator is installed on the grate frame, and the lower ash hopper is welded to the grate frame. The ash hopper is equipped with steam injection and oxygen distribution devices, and the ash scraper is installed under the ash hopper. The first gas outlet is connected to the purification system. There is an inner cylinder on the top of the furnace body, which forms a silo. There is a circular feeding port on the upper part of the inner cylinder, which is closed with a pneumatic valve. The purification system is composed of outlet spray, cyclone spray, spray system, cyclone dewatering, contactor dewatering, sewage treatment system and other parts.

[0024] The following will describe in detail with reference to the accompanying drawings in conjun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com