Cutting bed structure of ballast-less rail type high-speed railway in seasonal frozen-earth area

A ballastless track, high-speed railway technology, applied in the direction of roads, roads, buildings, etc., to achieve the effects of easy filling quality, simple construction technology, and high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings and embodiments.

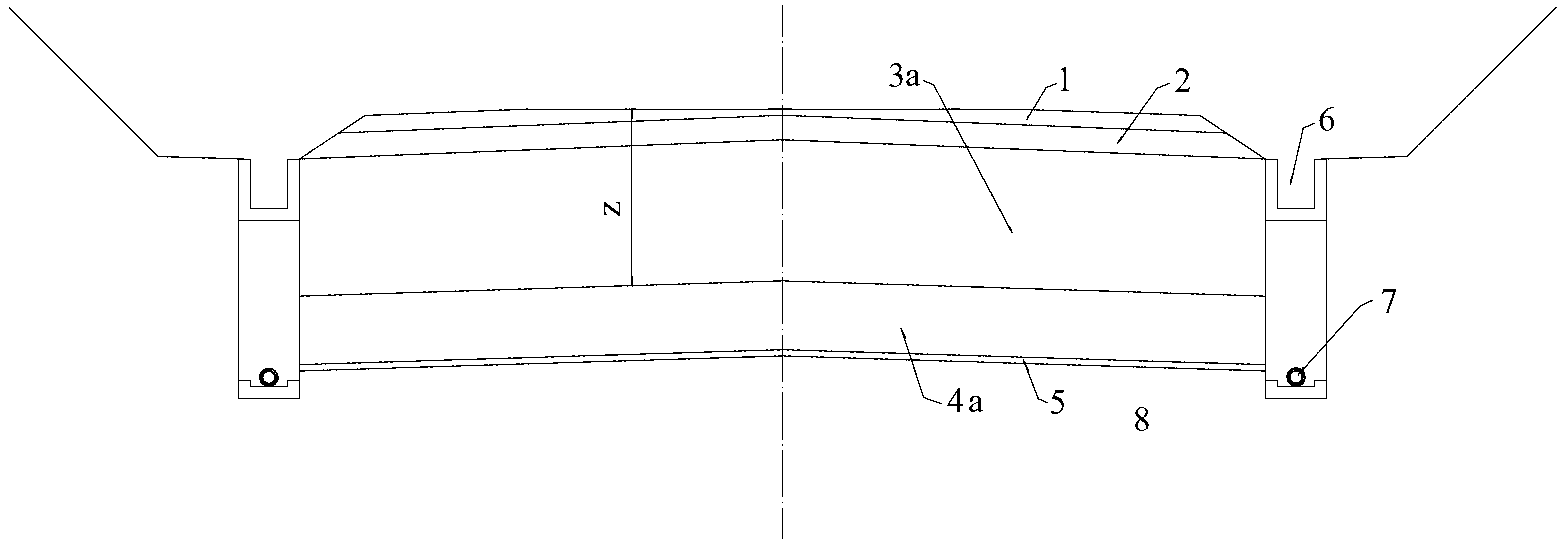

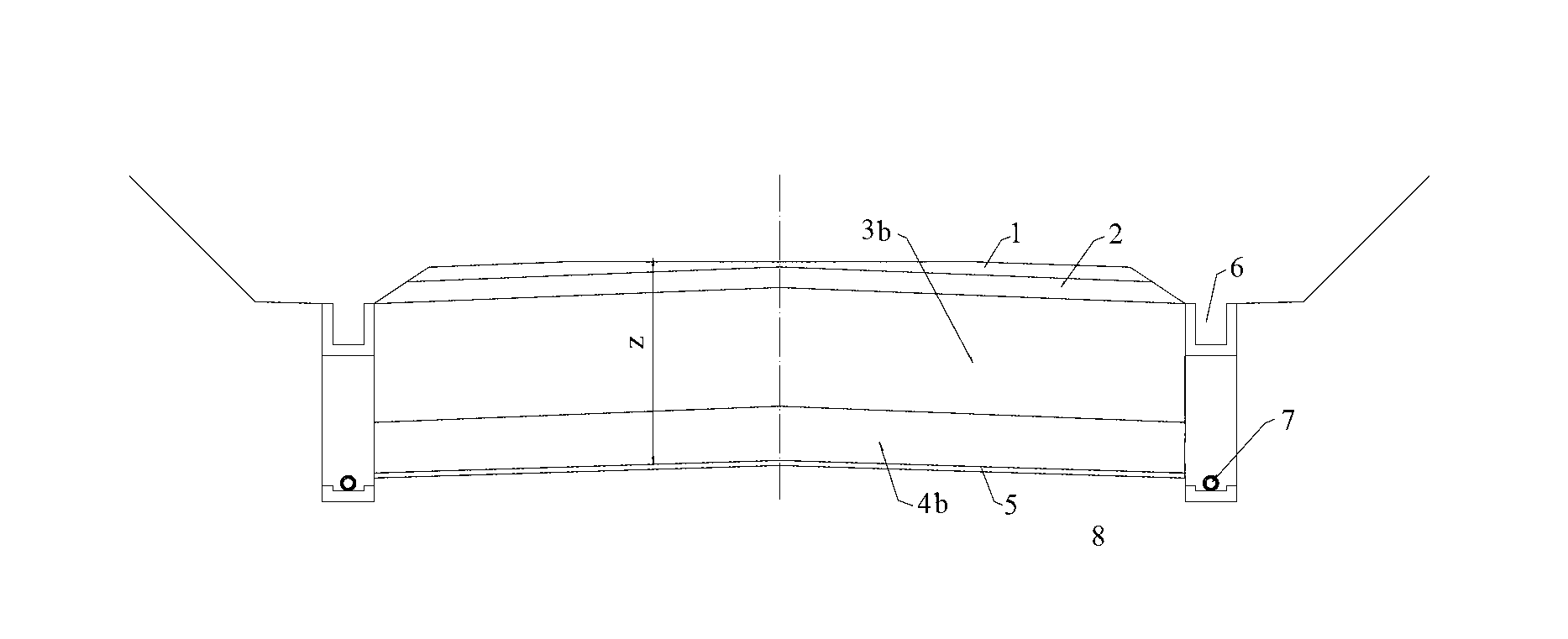

[0017] Reference figure 1 The illustrated embodiment 1, the subgrade bed structure of the ballastless track high-speed railway cut in the seasonal frozen soil area of the present invention, includes a composite layer that is laid or filled sequentially from bottom to top on the undisturbed soil layer 8 on the bottom surface of the subgrade replacement layer Waterproof and drainage layer 5, bottom layer 4a of subgrade bed, bottom layer 3a of drainage type bed, surface layer of drainage type bed 2, roadbed water-proof layer 1. Drainage structures are set on both sides of the subgrade bed, and the drainage surface elevation of the drainage structure under the drainage structure is lower than The elevation of the lower bottom surface of the composite waterproof and drainage layer 5; the design freezing depth Z of the road cutting subgrade is from the upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com