Construction method for side-slope platform pile-adding in-situ soil gravity-type retaining wall

A construction method and in-situ soil technology, applied in underwater structures, infrastructure engineering, water conservancy engineering, etc., can solve the problems of masonry costs, spoil pollution, unfavorable slope stability in the early stage, and achieve good overall stability. , the effect of reducing the project cost and protecting the original vegetation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

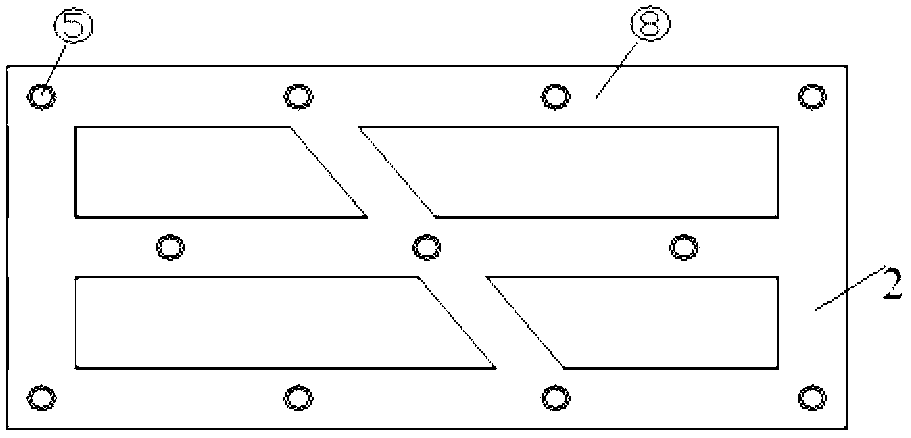

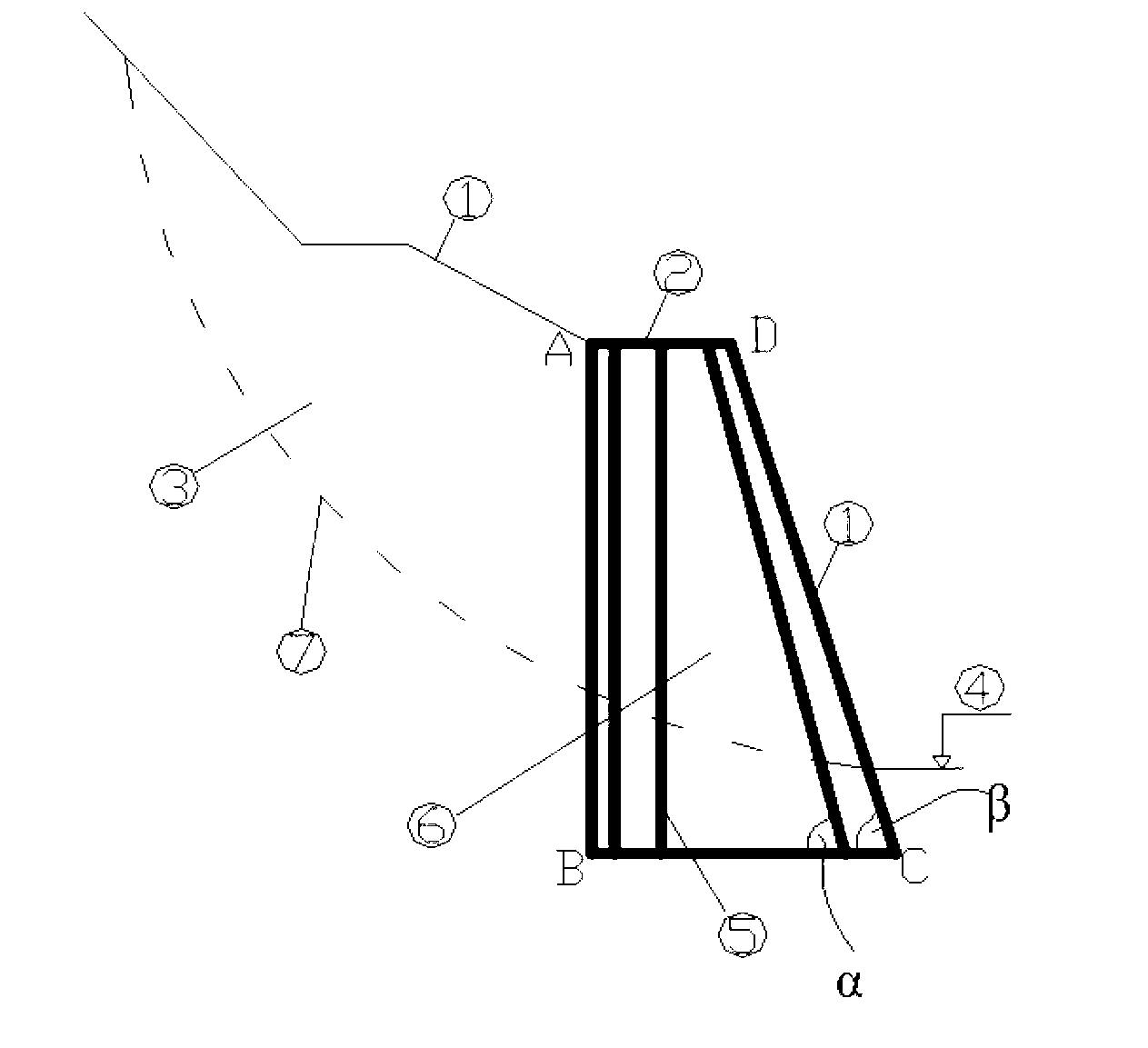

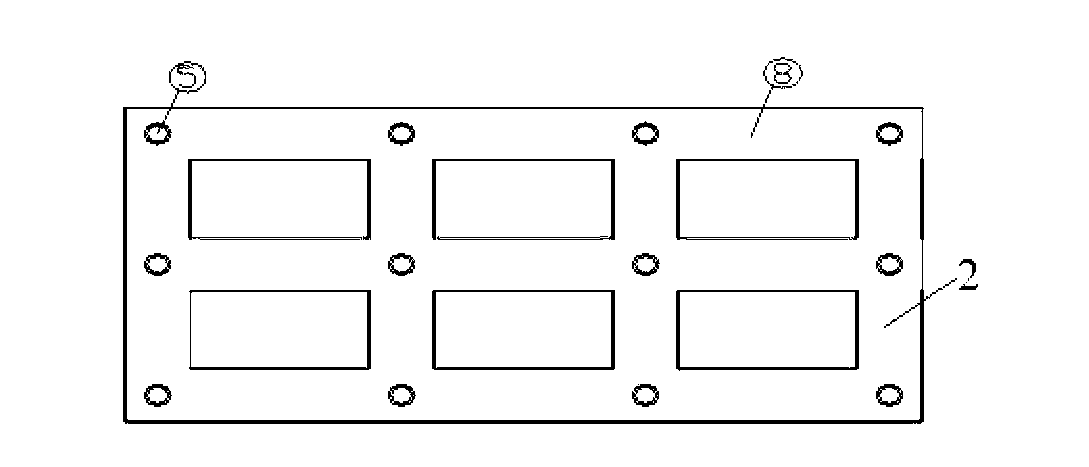

[0011] In-situ soil gravity retaining wall with piles added to slope platform figure 1 , where the ABCD area constitutes the retaining wall, and the entire retaining wall is composed of steel flower tubes ⑤, in-situ soil ⑥ and connecting beams ⑧ on the surface of the platform ②.

[0012] In the figure: ①slope ②first-level platform ③sliding mass ④ground ⑤steel pipe ⑥in-situ soil ⑦potential sliding surface ⑧connecting beam.

[0013] The construction includes the following steps: after leveling the site on the slope platform, after setting out the hole position, drilling the steel flower pipe hole, and adopting the grouting steel flower pipe technology after cleaning the hole: inserting the steel flower pipe, pressure grouting; excavating on the slope platform above the steel flower pipe The formwork groove of the contact beam is bound, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com