Self-deformation multi-axial puncture device

A piercer, multi-axial technology, applied in the direction of sampling device, etc., can solve the problem of inability to turn, achieve the effect of reducing damage and increasing puncture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

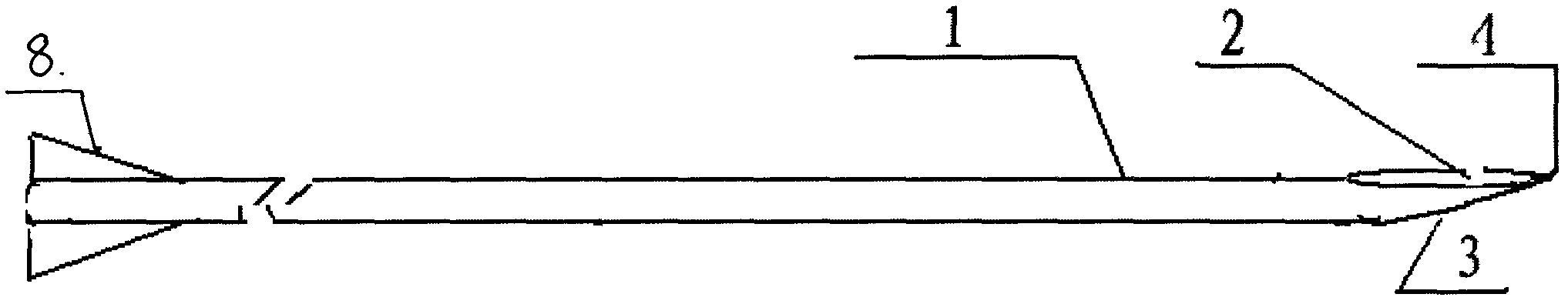

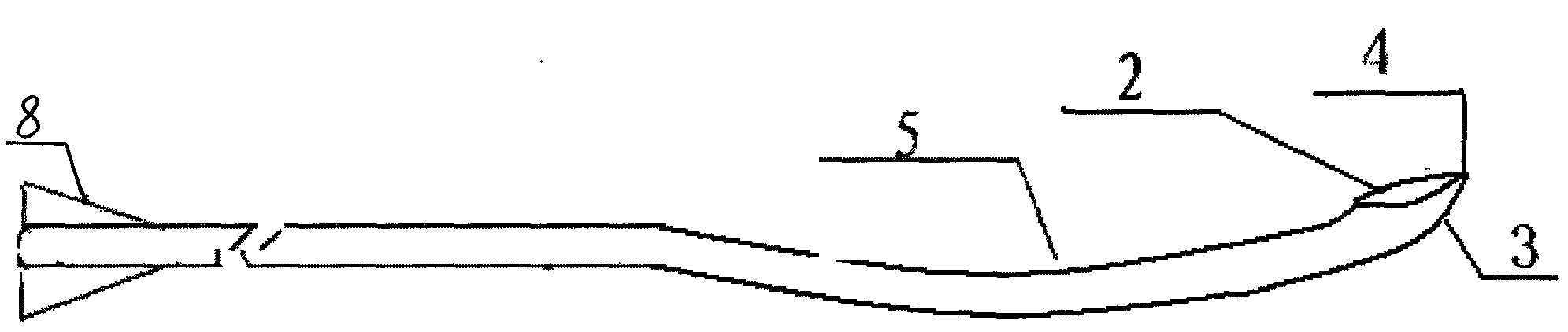

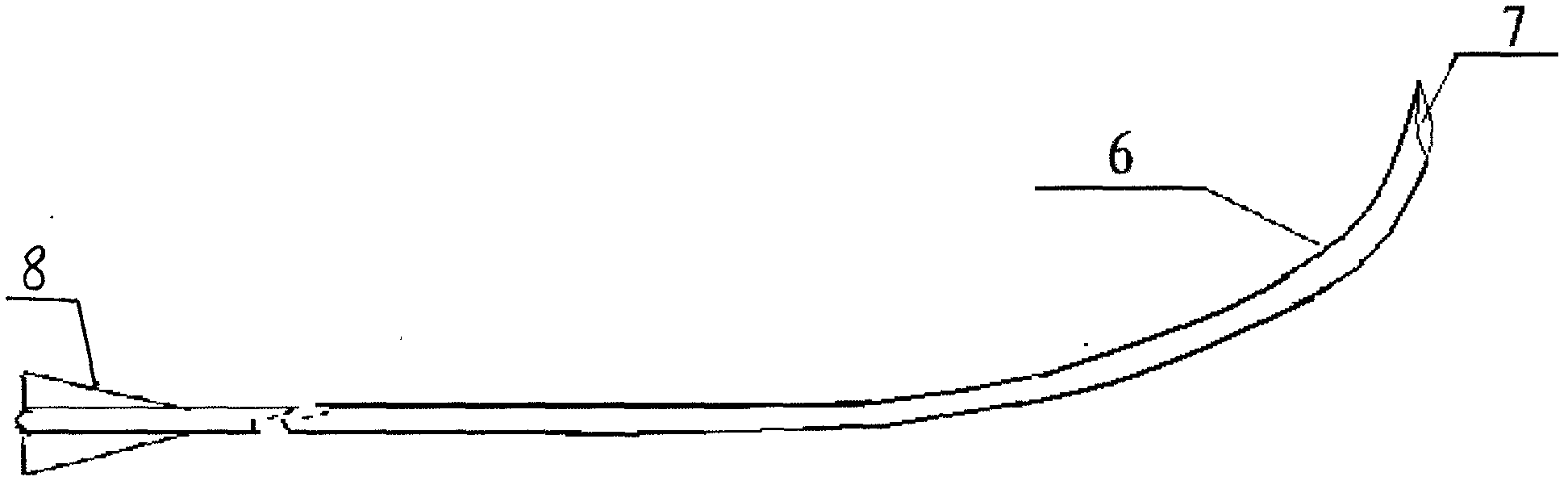

[0016] Embodiment 1: as Figure 4 The working principle of the self-deformable multiaxial puncture device with cold-thermal deformation is shown in the upper right quadrant. (6) Put the tail end of the puncture needle sleeve in a straight line into the sleeve by elastic extrusion and puncture the target together, then fix the puncture needle sleeve, push the puncture needle core forward, and the opening slope at the front end of the needle core (7 ) can smoothly slide and pass through the side hole (2) of the casing along the arc-shaped inclined wall (3) at the front end of the casing. When the temperature of the self-deformable multi-axial puncture device gradually rises above the metamorphosis temperature, the puncture needle sleeve becomes an arc-shaped curved shape. The needle core (6) bends and advances toward the direction of the side hole of the puncture needle sleeve under the guidance of the arc-shaped puncture needle sleeve (5), realizing turning. The arc bending o...

Embodiment 2

[0017] Example 2: If there are other directions to be operated after completing the operation in the front and upper directions, you can inject cold water or cold air from the puncture device to cool the puncture device below the metamorphosis temperature, and the puncture needle sleeve becomes a straight tube shape, and then insert the The puncture needle core is drawn back into the side hole of the puncture needle sleeve, and the puncture needle sleeve is rotated to operate in another direction. as in Figure 5 Middle: Rotate the cannula of the puncture needle by 180° arc to operate in the forward and downward direction (lower right quadrant). In this way, the puncture needle cannula can be continuously rotated from 0° to 360°, so that the operation at any angle and any position in the three-dimensional direction can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com