Cutter frame system of grating ruling engine

A grating scribing machine and scribing tool holder technology, applied in the direction of diffraction gratings, etc., can solve the problems of large processing and assembly, unfavorable large-area grating engraving, etc., to reduce difficulty, stabilize the scribing process, and reduce errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

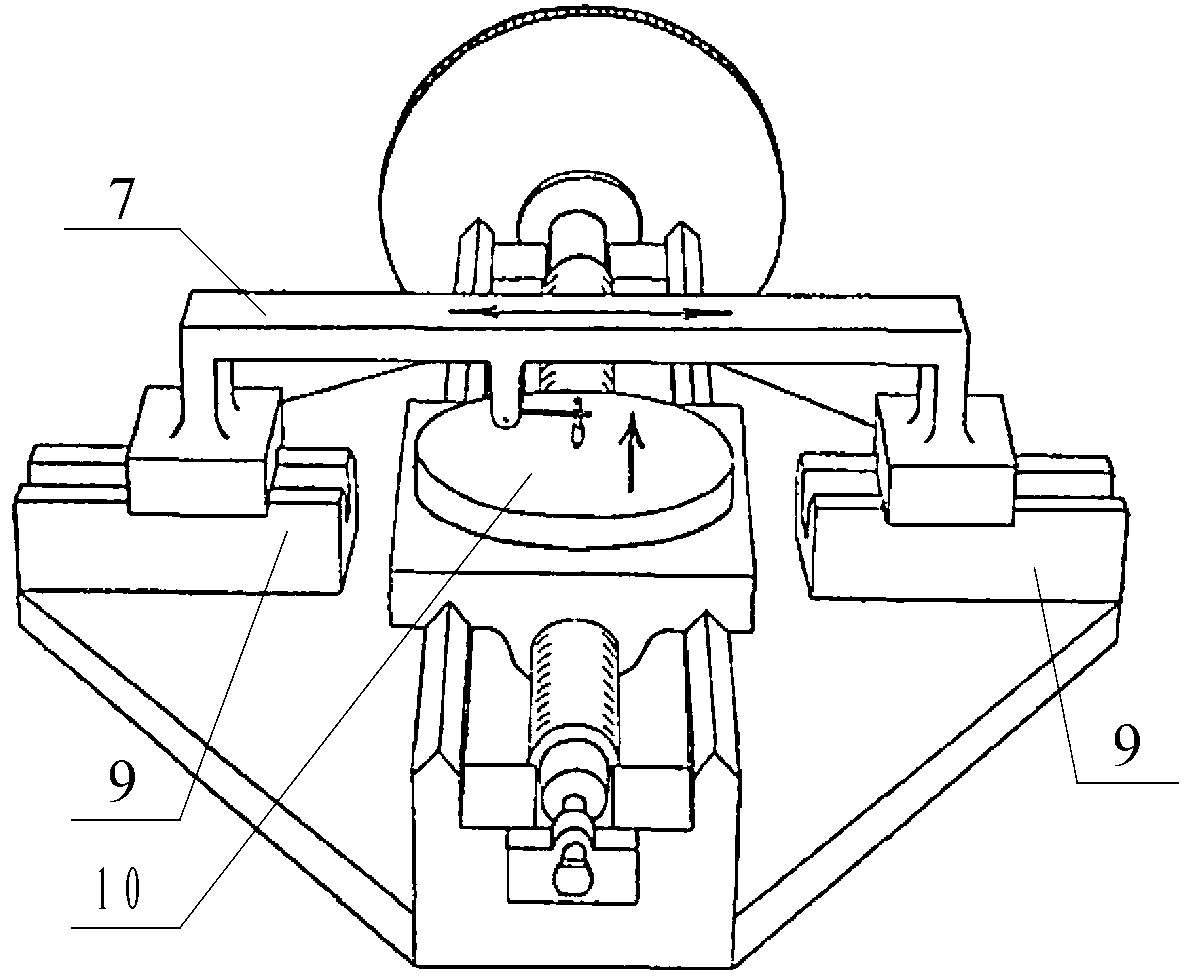

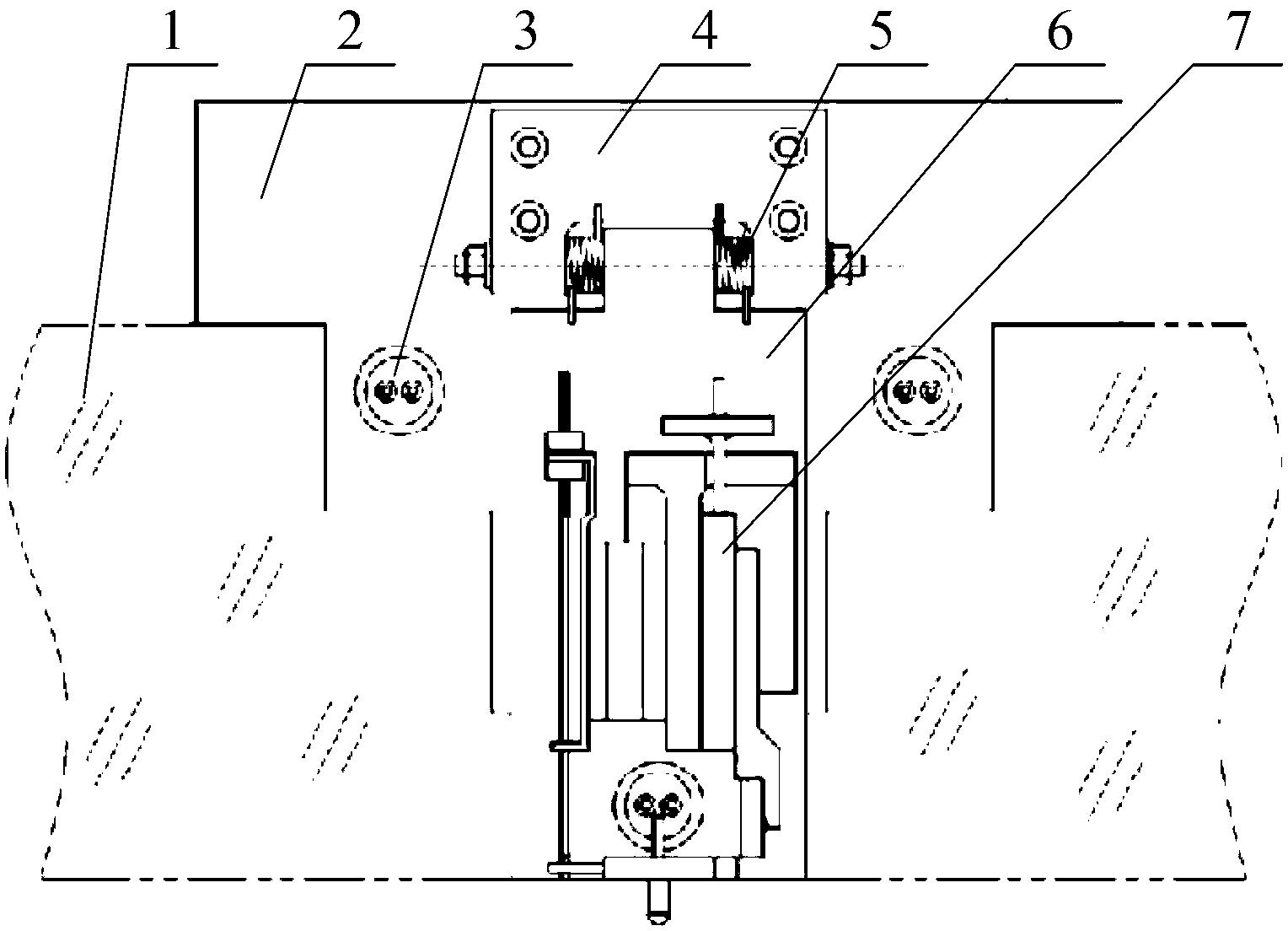

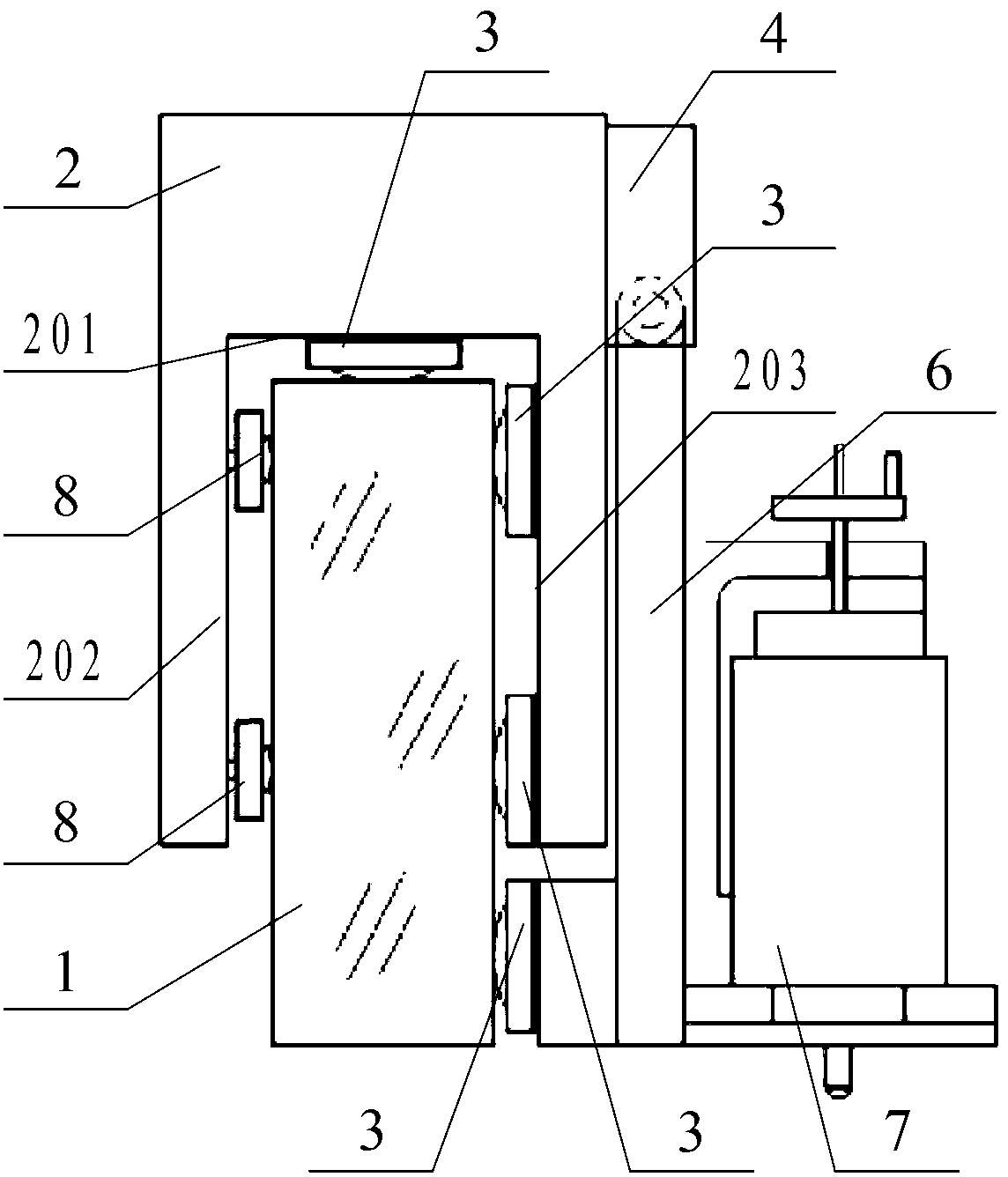

[0020] See attached figure 2 And attached image 3 , the grating marking machine tool holder system of the present invention includes guide rail 1, slider 2, elastic sliding foot 8, guide sliding foot 3, adapter 4, torsion spring 5, pin shaft, tool holder mounting plate 6 and marking knife Frame 7; the slider 2 is concave, and its concave interior has a horizontal surface 201, a first side surface 202, and a second side surface 203, and the horizontal surface 201 and the second side surface 203 accommodate the guide feet 3. The first side surface 202 places the elastic sliding feet 8; the slider 2 straddles the guide rail 1, and contacts the guide rail 1 through the elastic sliding feet 8 and the guide sliding feet 3 , the slider 2 can slide along the guide rail 1 .

[0021] The adapter 4 is fixedly connected with the slider 2, the adapter 4 is fixed on the slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com