Flip-chip welding spot defect back view temperature measurement detecting method

A flip-chip and flip-chip welding technology, which is applied in the field of chip solder joint defect detection, can solve the problem that the detection technology cannot meet the actual needs of production, and achieve the effects of a wide range of applicable processes, defect identification rate, and high identification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited to this. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the technical solution of the present invention. in the scope of protection.

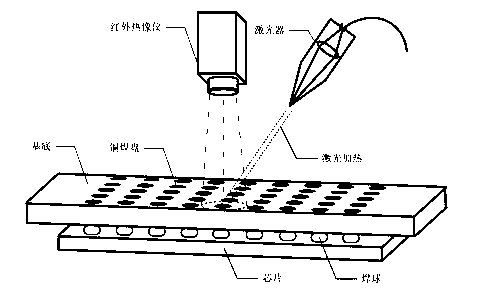

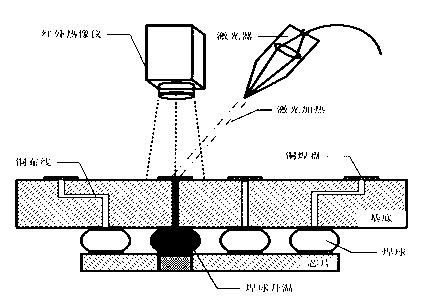

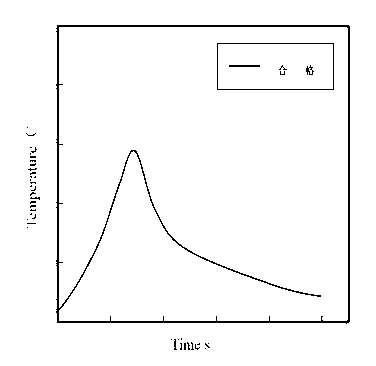

[0026] Such as figure 1 As shown, a thermal imager and an infrared laser are respectively arranged on the substrate side of the flip chip, and the diameter of the laser beam is slightly smaller than that of the bonding pad. Aim the infrared laser beam at the pad to be tested on the flip chip substrate, adjust the power and pulse width parameters, and apply thermal excitation to it, that is, input a fixed amount of heat to the pad, during which the temperature of the pad rises rapidly , the heat is conducted to the solder balls an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com