Automatic page turning scanner

An automatic page-turning and scanning machine technology, applied in bookmarks, printing, electrical components, etc., can solve the problems of page-turning accuracy, stability impact, uneven rubbing force, and inability to rub the pages, so as to avoid the confusion of the pages. , to achieve automatic page turning, easy to fix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

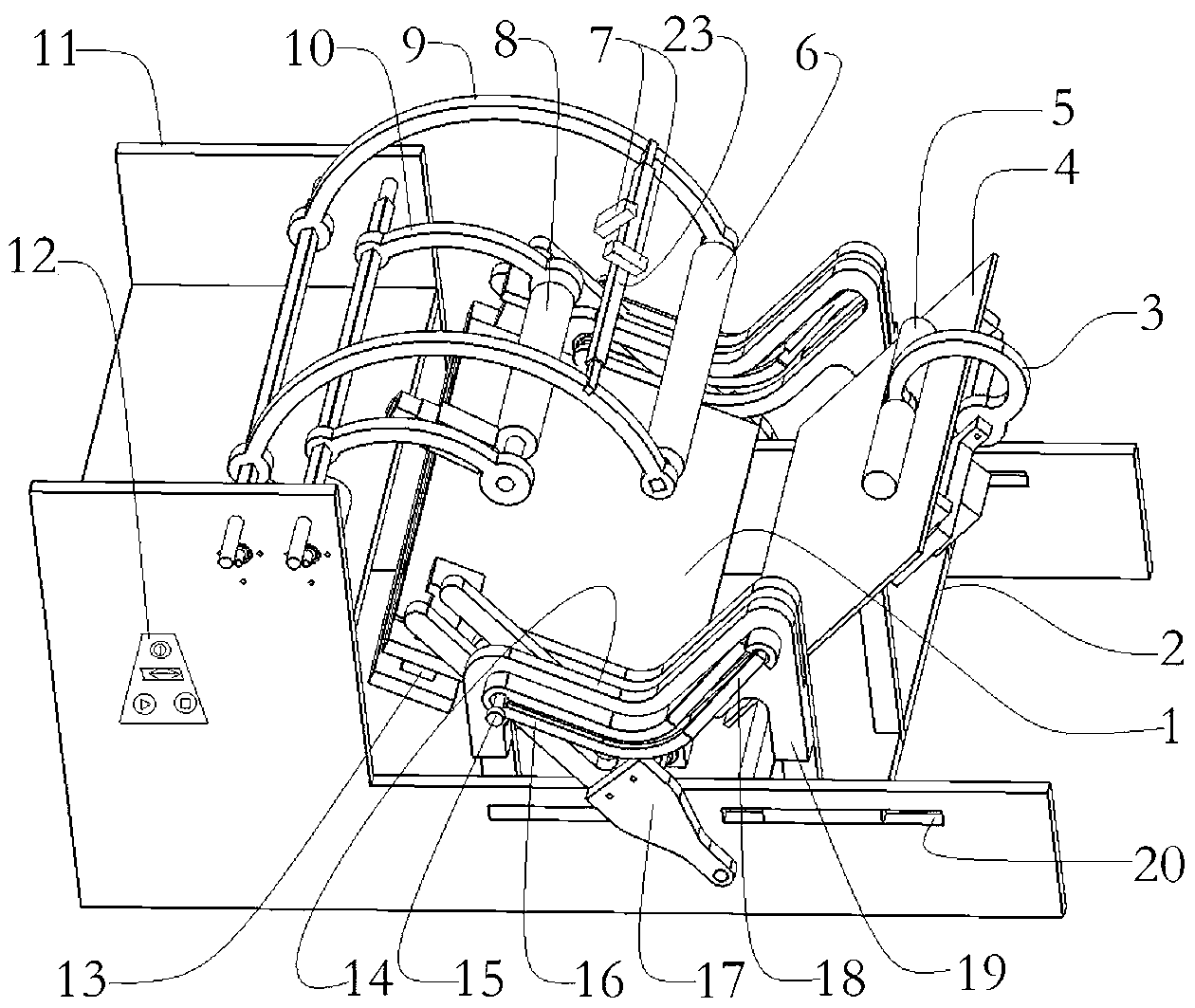

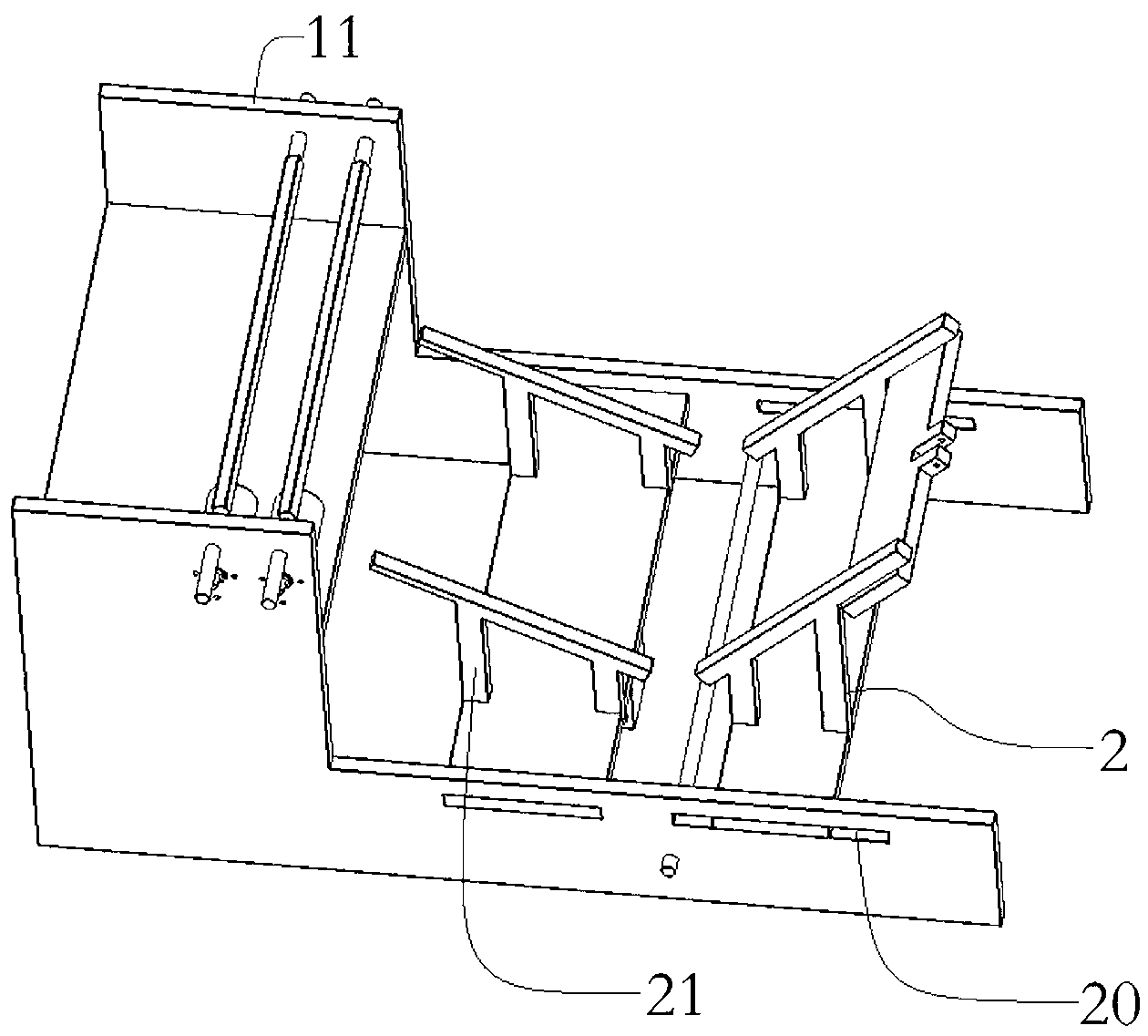

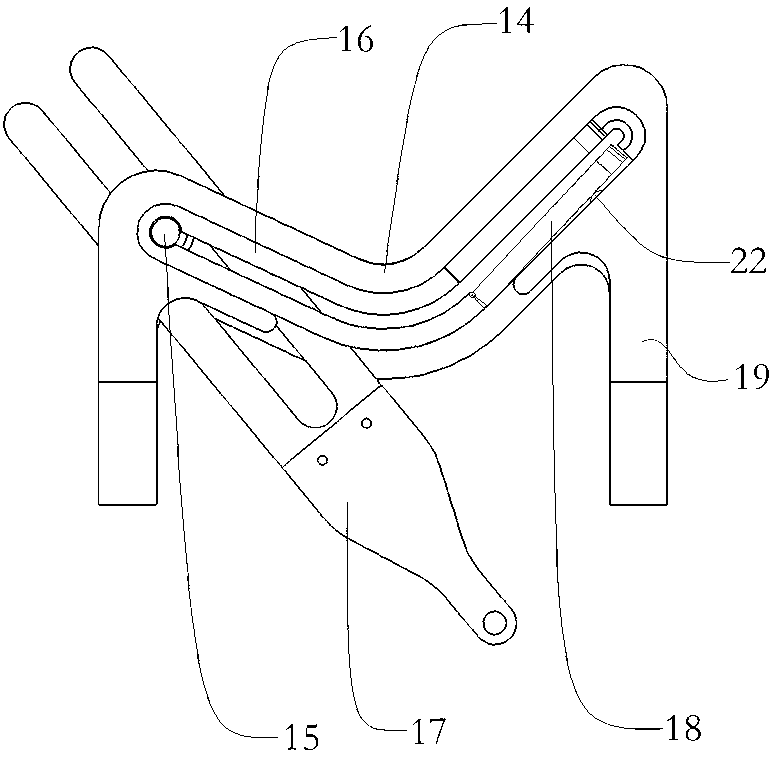

[0021] See also attached Figure 1-4, the structure of a specific embodiment of the present invention includes a frame 11, the frame 11 is provided with a fixing device, a page turning device, a scanning element 7, a control system and an operation panel 12, and the fixing device includes fixing by a fixed frame 21 The workbench I1 set on the frame 11, the workbench II4 set on the frame 11 through the sliding frame 2, the page edge clip 13 set on the workbench I1, are movably connected to the machine through the pick rod 9. The presser hand I6 on the frame 11 and suspended above the workbench I1, the arc bar 3 movably connected to the back of the workbench II4, and the presser hand II5 connected to the arc bar 3 and suspended above the workbench II4, said The sliding frame 2 is movably arranged in the chute 20 on the side wall of the frame 11 and is controlled by the motor I. The angle between the workbench I1 and the workbench II4 is 150°, and it is connected to the V-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com