Method and arrangement for forming a dental model

A technology for dental molds and components, applied in dentistry, mold cups, teaching models, etc., which can solve the problems of long manufacturing duration, cost disadvantages, and limited competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

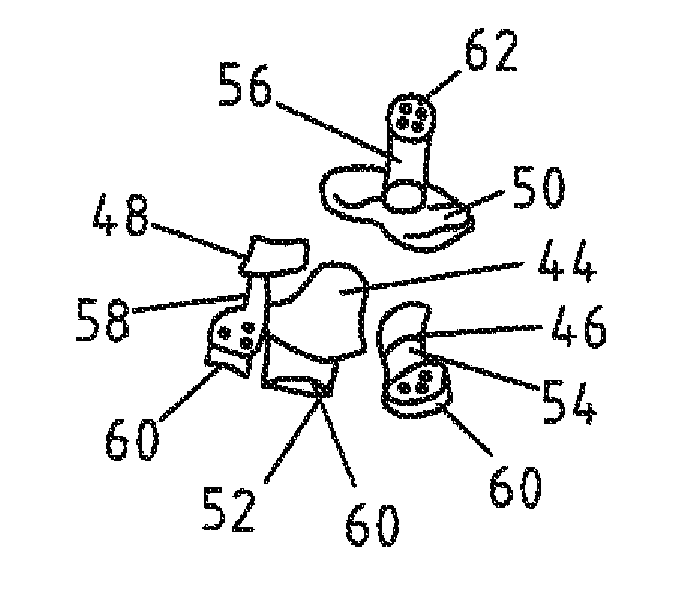

[0103] Corresponding to the teachings according to the present invention, in order to manufacture artificial teeth, the lower and upper jaws of the patient are measured in the oral cavity to obtain digital 3D data. The tooth contact field and the surrounding motion field adjacent to the center are then also preferably measured intraorally at least in bite, that is to say in the center of the upper and lower jaw. The centered relationship of the lower and upper jaws to each other is obtained from the scanned sides of the teeth in contact or the scans of the wax bite mold (ie elements arranged between the superimposed upper and lower jaws, such as silicone elements). The data on this may be taken into account if necessary (corresponding to the previous explanation regarding the field of motion of the jaw joint in the separation and, if necessary, the elastic strength field during forced occlusion, with additional consideration of the elastic strength of the individual teeth) In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com