All-pole combined sugarcane harvester

A combine harvester and pole-type technology, which is applied in the direction of harvesters, agricultural machinery and implements, etc., can solve the problem that the gearbox drive cannot ensure the smooth running of sugarcane at low speed, and it is not suitable for different types of sugarcane leaf stripping, broken tails, etc. Highland ridge operation and other problems, to achieve good promotion and application prospects, adjustable ground clearance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

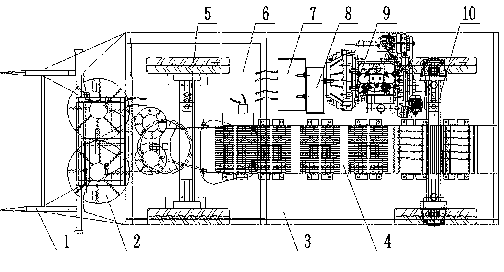

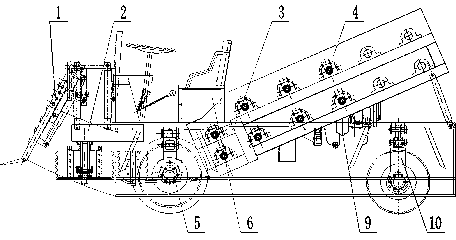

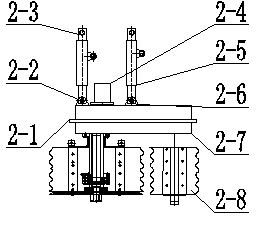

[0035] The whole-rod sugarcane combine harvester of the present invention includes a traveling system and a working system. The system mechanism includes: traveling mechanism, frame and cane supporter arranged on the frame in sequence, cab, header assembly, leaf stripping channel assembly, front axle, rear axle, travel drive hydraulic motor, travel drive And work to drive hydraulic pumps, transfer cases or gearboxes, engines. The stripping channel assembly has several pairs of stripping impellers that rotate relatively up and down, and each stripping impeller is provided with several stripping blades. The frame is the base frame of the harvester, and the feature is that the front part of the frame is set as a high-level frame, which is higher than the rear part of the frame. The cane supporter and the header are connected and installed on the high-level frame through pins and hydraulic cylinders, and the cane supporter is equipped with a sheet metal cane divider; the heade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com