Clamping device and clamping and positioning method thereof

A technology of clamping device and pressing screw, applied in the direction of positioning device, clamping, support, etc., can solve the problems of affecting the product quality of the workpiece to be positioned, the surface of the workpiece is crushed, and the auxiliary positioning time is long, so as to improve the workpiece quality. The effect of positioning efficiency, improving clamping efficiency, and quick and convenient positioning adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

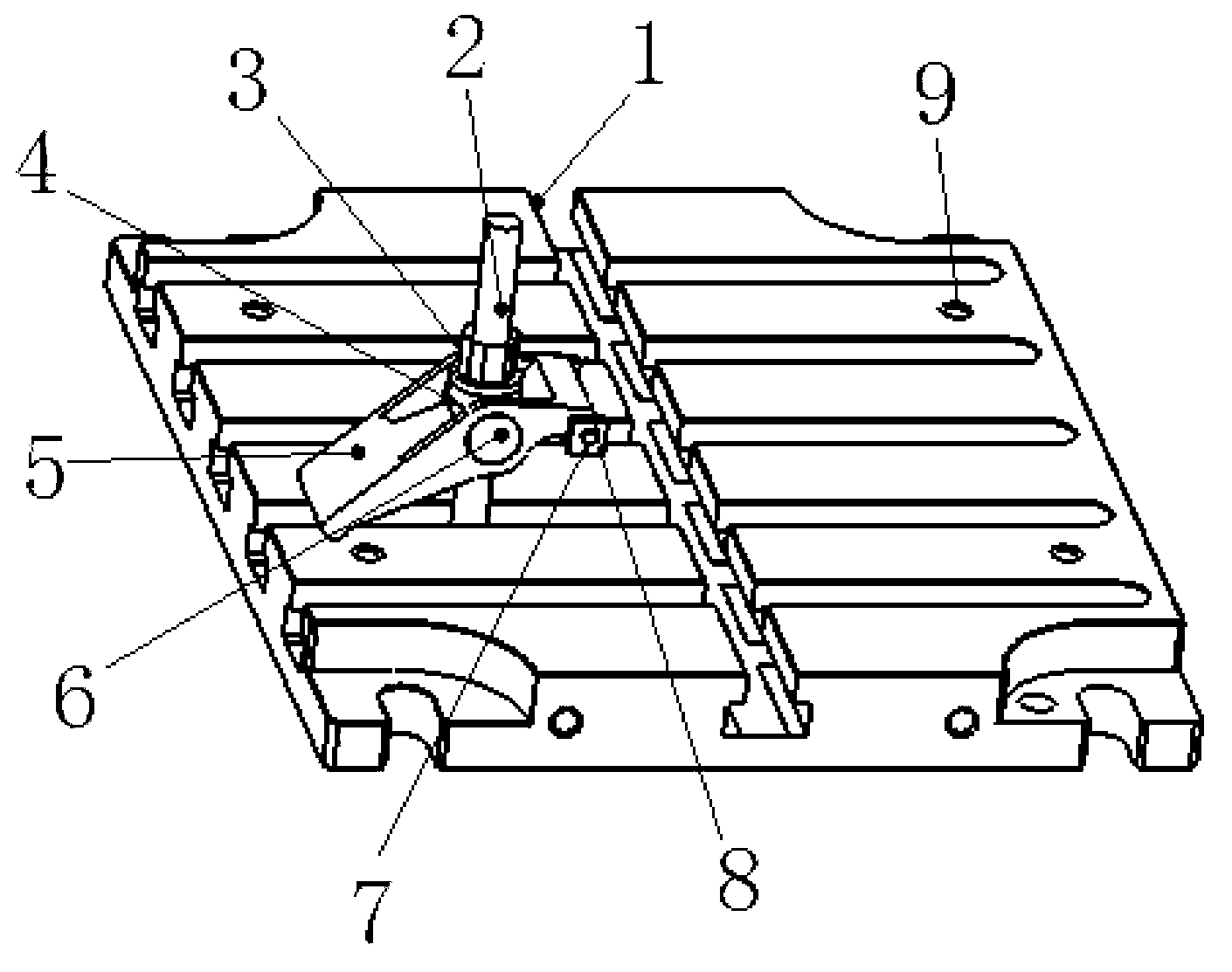

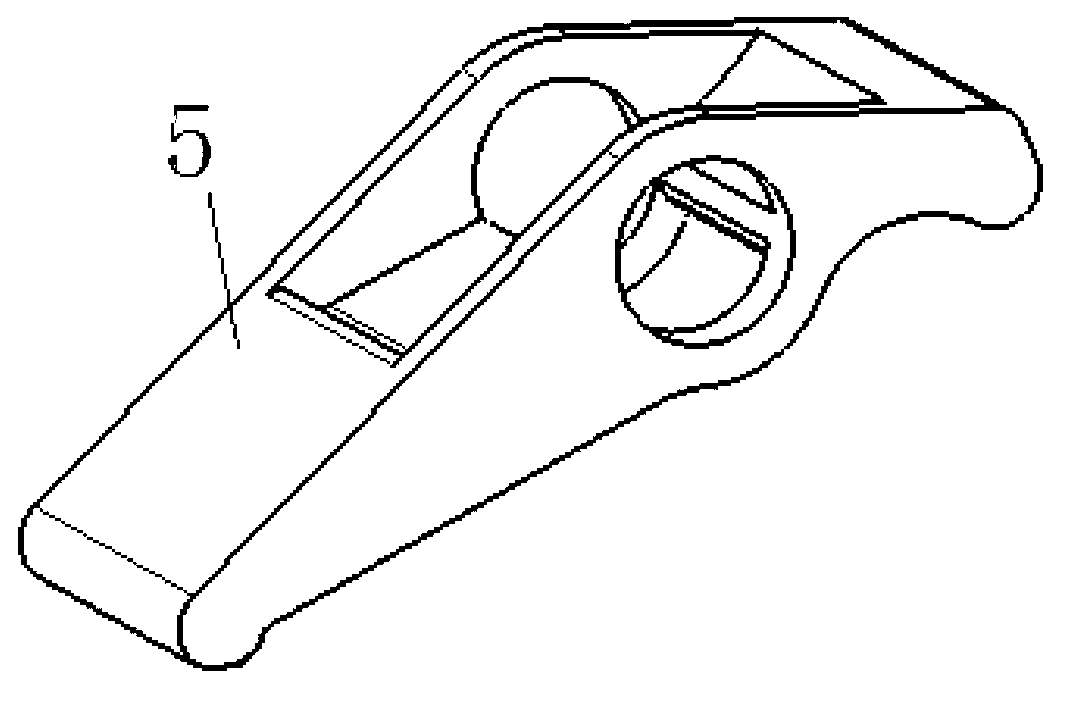

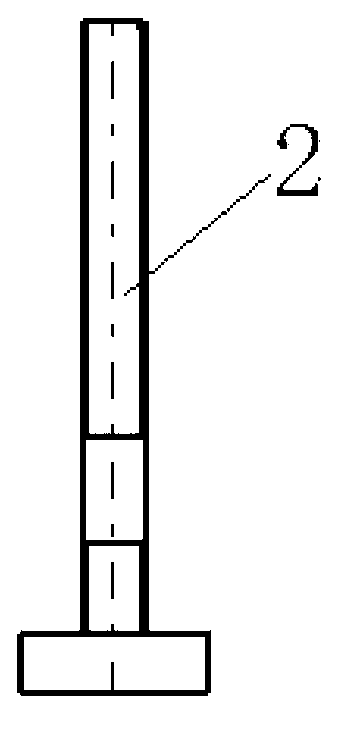

[0032] Such as Figure 1 to Figure 7 As shown, the clamping device is used for the positioning of workpieces such as die forging inserts and steel plates, and includes an auxiliary workbench 1 and an arc-shaped pressure plate 5. A compression screw 2 is provided on the auxiliary workbench 1. A pressing plate rotating shaft 6 is provided; the middle part of the pressing plate rotating shaft 6 passes through the pressing screw 2, one end of the arc-shaped pressing plate 5 is in contact with the auxiliary workbench 1, and the other end of the arc-shaped pressing plate 5 is provided with a pressing plate 8 for pressing the workpiece to be positioned. The pressing plate 8 is pressed against the surface of the workpiece;

[0033] The nut washer 4 adapted to the lock nut 3 is arranged on the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com