High-solid content quick-drying modified starch lap adhesive and preparation method thereof

A fast-drying, high-solid-content technology, applied in the direction of starch adhesives, adhesive types, non-polymer adhesive additives, etc., can solve the problem of decreased fluidity of starch adhesives, difficulty in machine movement, and unsuitability for high-speed cigarettes Machine and other problems, to reduce preparation time, reduce costs, save electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 18.52 kg of deionized water and add it to the reaction kettle, turn on the stirring device, set the stirring speed to 200 rpm, slowly add 14.96 kg of corn starch and 0.012 kg of α-starch liquefying enzyme into the kettle, and stir for 5 minutes Finally, turn on the heating device, set the oxidation temperature to 50°C, and continue to add 1.28 kg of NaClO to the kettle, stir for 10 minutes, and set the gelatinization temperature to 92°C again. After the temperature reaches, add 1.8 kg of NaOH in sequence , 3.2 kg of nano sepiolite powder and 0.024 kg of N-hydroxyethyl acrylamide, stirred for 0.8 hours, high-temperature enzyme inactivation was carried out while the gelatinization reaction was completed, and then 0.04 kg of 1,2-benzisothiazole was added -3-ketone and 0.16 kg of absolute ethanol, continue to stir for 0.6 hours and leave it to cool and discharge to obtain 40 kg of high-solid fast-drying modified starch lap glue.

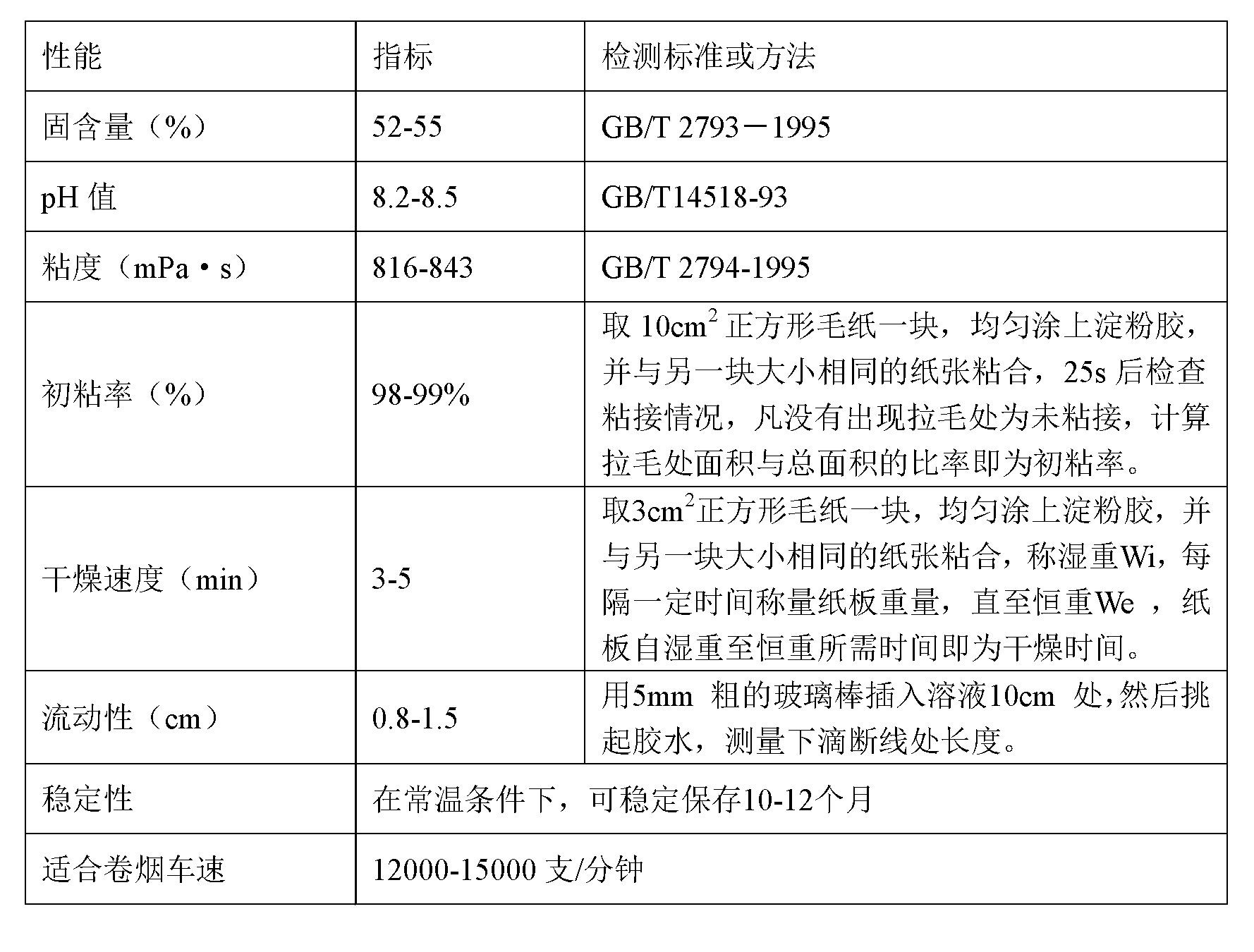

[0027] After testing, the solid conten...

Embodiment 2

[0029] Take 27.7 kg of deionized water and add it to the reaction kettle, turn on the stirring device, set the stirring speed to 240 rpm, slowly add 23.1 kg of tapioca starch and 0.012 kg of α-starch liquefying enzyme into the kettle, and stir for 6 minutes Finally, turn on the heating device, set the oxidation temperature to 52°C, and continue to add 1.2 kg of NaClO to the kettle, stir for 12 minutes, and set the gelatinization temperature to 93°C again. After the temperature reaches, add 2.4 kg of NaOH in sequence , 5.4 kg of nano sepiolite powder and 0.03 kg of N-hydroxyethyl acrylamide, stirred for 0.8 hours, high-temperature enzyme inactivation was carried out while the gelatinization reaction was completed, and then 0.036 kg of 1,2-benzisothiazole was added -3-ketone and 0.12 kg of dehydrated alcohol, continue to stir for 0.6 hours and leave it to cool to discharge, so as to obtain 60 kg of high-solid quick-drying modified starch lap glue.

[0030] After testing, the sol...

Embodiment 3

[0032] Take 36.5 kg of deionized water and add it to the reaction kettle, turn on the stirring device, set the stirring speed to 260 rpm, slowly add 31.28 kg of corn starch and 0.016 kg of α-starch liquefying enzyme into the kettle, and stir for 8 minutes Finally, turn on the heating device, set the oxidation temperature to 51°C, and continue to add 2.4 kg of NaClO to the kettle, stir for 10 minutes, and set the gelatinization temperature to 92°C again. After the temperature reaches, add 3.68 kg of NaOH in sequence , 5.6 kilograms of nano sepiolite powder and 0.056 kilograms of N-hydroxyethylacrylamide, stirred for 0.5 hours, carried out high-temperature enzyme inactivation while completing the gelatinization reaction, and then added 0.064 kilograms of 1,2-benzisothiazole -3-ketone and 0.4 kg of absolute ethanol, continue to stir for 0.5 hours and then leave it to cool and discharge to obtain 80 kg of high-solid quick-drying modified starch lap glue.

[0033] After testing, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com