Mechanics loading type bioreactor capable of carrying out online measurement

A bioreactor and mechanical technology, applied in the mechanical loading bioreactor constructed by bone tissue, in the field of cartilage in vitro, can solve problems such as poor mechanical strength, and achieve the effect of simple operation, strong practicability, and timely and accurate control response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

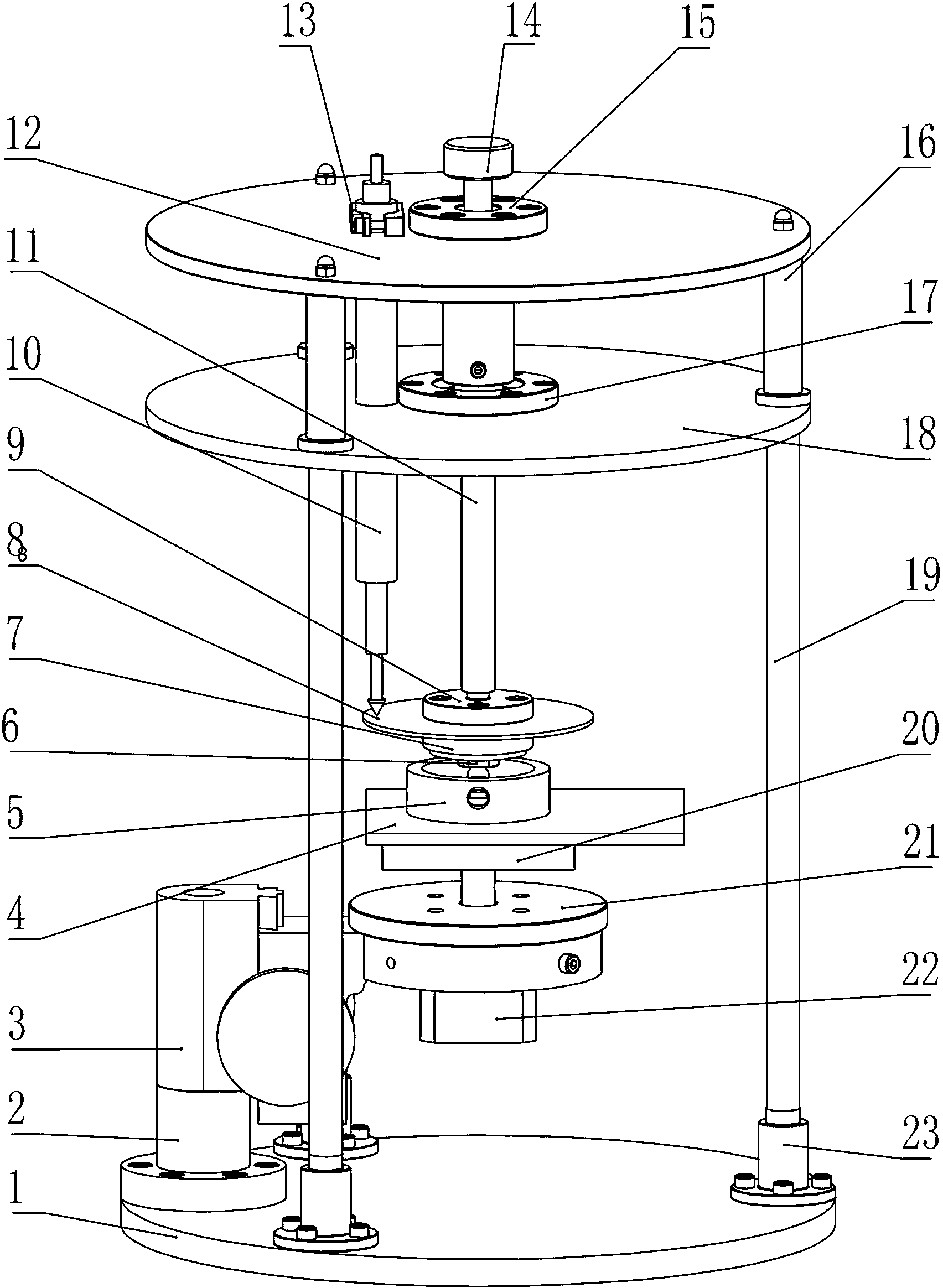

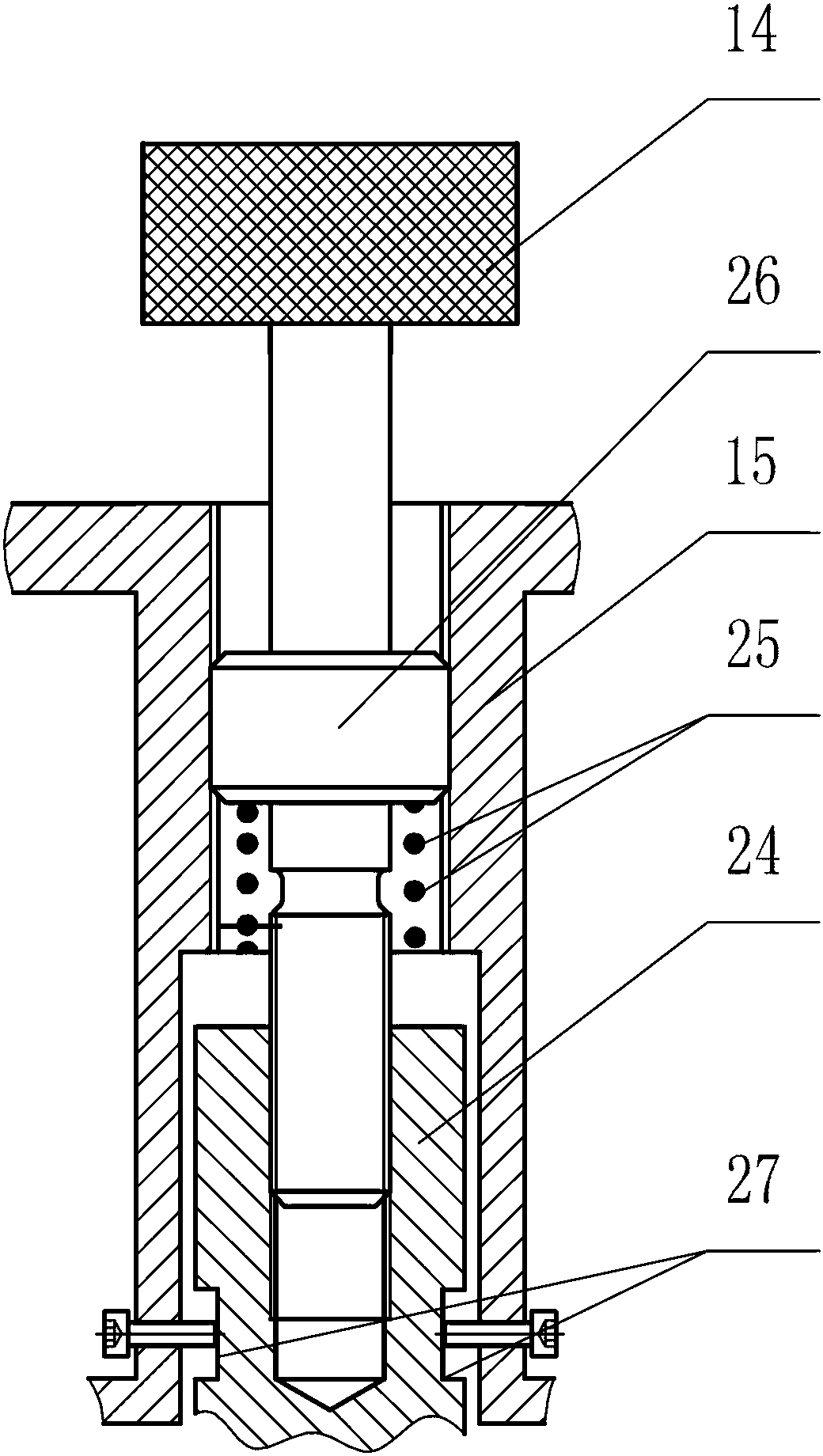

[0019] Specific implementation mode one: as figure 1 and figure 2 As shown, the mechanically loaded bioreactor that can be measured online in this embodiment includes a base 1, a support shaft 2, a rack and pinion mechanism 3, a weight sensor 4, a culture platform 5, a pressure head 6, a bacteria isolation loading platform 7, a test Sheet 8, connector 9, displacement sensor 10, piezoelectric ceramic micro-displacement brake 11, first support disc 12, locking device 13, stud 14, spiral outer sleeve 15, spiral inner sleeve 24, cylindrical spring 25, guide cylinder 17. The second support disc 18, turntable 20, cover cup 21, stepper motor 22, three sleeves 16, three support rods 19 and three correction flanges 23, the rack and pinion mechanism 3 is fixed by the support shaft 2 Installed on the upper end surface of the base 1, the lower end of each support rod 19 is fixed on the upper end surface of the base 1 through a rectification flange 23, and the three support rods 19 are e...

specific Embodiment approach 2

[0030] Specific implementation mode two: as figure 1 As shown, the stud 14 of this embodiment is made of brass. This design reduces the friction between the stud and the inner and outer shell of the screw, which is convenient for operation. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation mode three: as figure 1 As shown, the support rod 19 of this embodiment is made of stainless steel. So designed to avoid rust. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com