A block multi-stage inflatable composite structure fabric

A composite structure and segmented block technology, which is applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of loss of use function, increase of fabric rigidity, and limited insulation effect, and achieve enhanced insulation effect, reduced convection, and strong protection effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 illustrates the structure in conjunction with the accompanying drawings

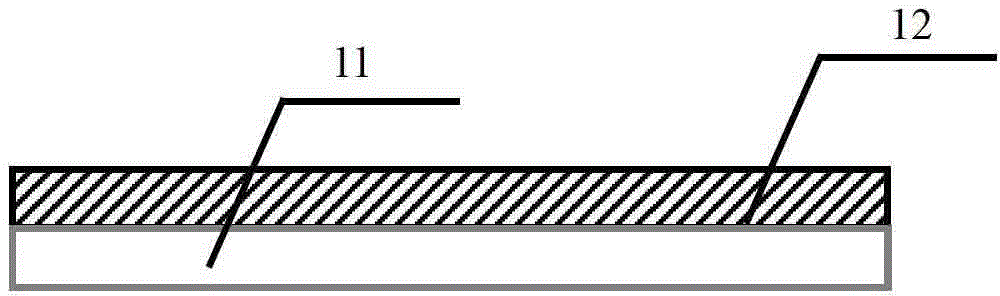

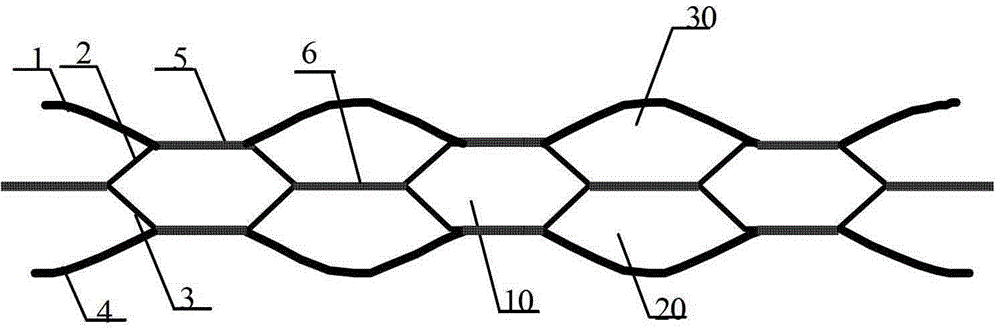

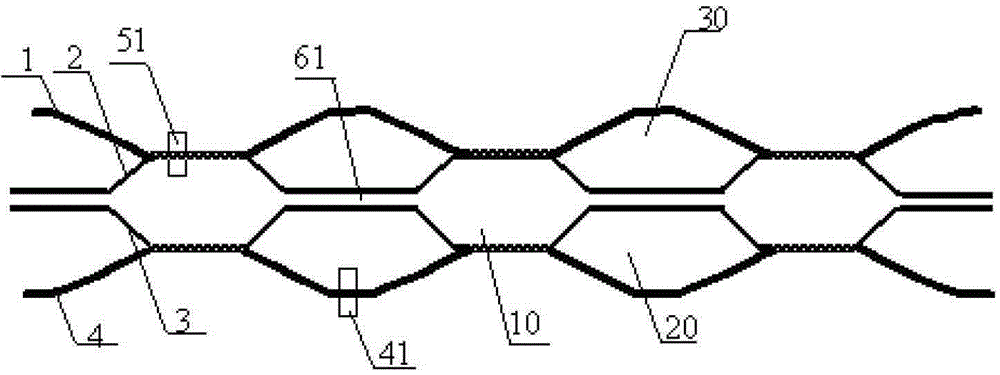

[0029] see figure 1 , 2 , 3, 4, in the figure, 1 is the first layer of fabric, 2 is the second layer of fabric, 3 is the third layer of fabric, 4 is the fourth layer of fabric, 5 is the outer layer connecting belt, 6 is the inner layer connecting belt, 11 is the fabric, 12 is the coating, 10 is the inner air chamber, 20 is the first outer air chamber, 30 is the second outer air chamber, 41 is the outer air inlet, 51 is the inner air inlet, 52 is the outer air inflation channel, 61 Inflate channels for the inner layer.

[0030] figure 1 is a schematic diagram of the structure of the coated fabric. The fabric 11 is formed of high-density polyester, nylon or other materials. The coating 12 is polyurethane, polyvinyl chloride or polyacrylate, etc., and the fabric 11 is coated on one side by scraping and calendering. Wherein the coating 12 partially penetrates into the fabric 11 .

...

Embodiment 2

[0035] Embodiment 2 production process

[0036] After coating, the second layer of fabric 2 and the coated third layer of fabric 3 are coated with adhesive according to the required size intervals for bonding to form an inner layer connection belt 6 . A 2-3 cm wide non-adhesive gap is left laterally at an appropriate place in the bonding area (that is, the inner layer connection belt 6 ) to form an inner layer inflation channel 61 , and an inner inflation port 51 is provided at an appropriate position. Put the first layer of fabric 1 after coating and the fourth layer of fabric 4 after coating according to figure 2 As shown, adhesive agent is coated on the unbonded part of the second layer of fabric 2 and the third layer of fabric 3 and parallel to the inner layer connection belt 6 for bonding to form the outer layer connection belt 5 . Leave the outer layer inflation channel 52 at the bonding place of the first layer of fabric 1 and the fourth layer of fabric 4 periphery, o...

Embodiment 3

[0037] Embodiment 3 specifications and performance

[0038] The composite fabric material used in the experiment is plain polyester fabric coated with PU on one side. The warp density is 680 threads / 10cm, the weft density is 386 threads / 10cm, the thickness is 0.25mm, and the surface density is 102.05g / m2. In the experiment, the critical length of the bonding lap is 2cm, and the inflation pressure of the gas is 0.5Mpa. Such as figure 1 The four-layer fabric is coated on one side with PU and bonded using neoprene as an adhesive. The inflation specification is shown in Table 1, and the heat insulation effect is shown in Table 2.

[0039] Table 1

[0040]

[0041] Table 2

[0042]

[0043] In the present invention, the flexible composite structural material composed of multiple layers of inflated and separately inflated air chambers improves the heat preservation performance by 126.9% to 152.18% compared with single-layer common coating materials. The fully inflated fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com