Method for preparing polyaspartic acid nano hydrogel felt

A nano-hydrogel and polyaspartic acid technology, which is applied in textiles and papermaking, fiber treatment, non-woven fabrics, etc., can solve the problem of difficult control of polyaspartic acid electrospinning, and achieve a simple spinning process Easy to control, uniform fiber and small fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Polysuccinimide is self-made in the laboratory, the raw material is L-aspartic acid, purchased from Aladdin, the purity is 99%, and the specification is A108860-500g. The synthesis method of polysuccinimide is as follows: put finely ground L-aspartic acid and 259g of 85% phosphoric acid in a 2L flask and mix evenly, and react under reduced pressure on a rotary evaporator at 180°C for 2.5h to remove the original water and the water produced by the reaction. After cooling slightly, 200 mL of DMF was added to dissolve the massive solid formed, and the solution was poured into a beaker containing 1 L of distilled water. Filter and wash the precipitate with water until neutral. Vacuum-dried at 110°C for 24 hours to obtain polysuccinimide with a molecular weight of 30,000.

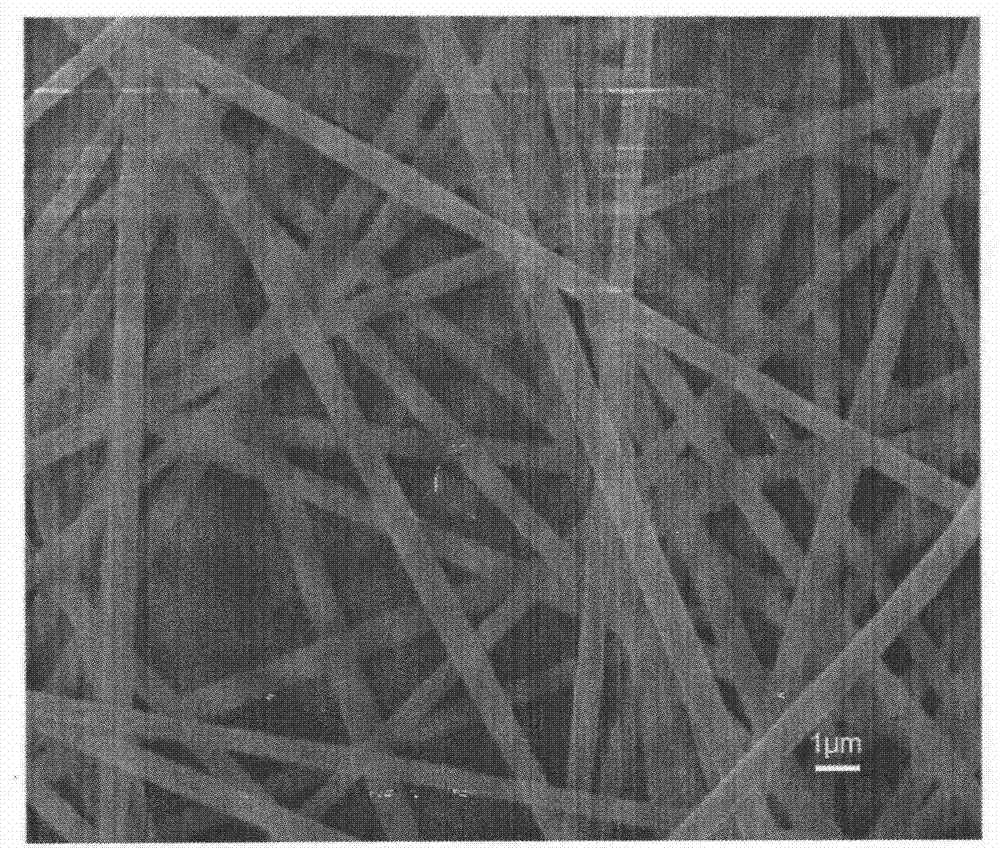

[0024] 2. Dissolving polysuccinimide in dimethylformamide, the mass fraction of the solution is 30%. After stirring completely to dissolve, stand still for degassing and spinning, set the advancing ...

Embodiment 2

[0028] 1. Polysuccinimide is self-made in the laboratory, the raw material is L-aspartic acid, purchased from Aladdin, the purity is 99%, and the specification is A108860-500g. The synthesis method of polysuccinimide is as follows: put finely ground L-aspartic acid and 259g of 85% phosphoric acid in a 2L flask and mix evenly, and react under reduced pressure on a rotary evaporator at 180°C for 2.5h to remove the original water and the water produced by the reaction. After cooling down slightly, 200 mL of DMF was added to dissolve the massive solid formed, and the solution was poured into a beaker containing 1 L of distilled water. Filter and wash the precipitate with water until neutral. Vacuum-dried at 110°C for 24 hours to obtain polysuccinimide with a molecular weight of 30,000.

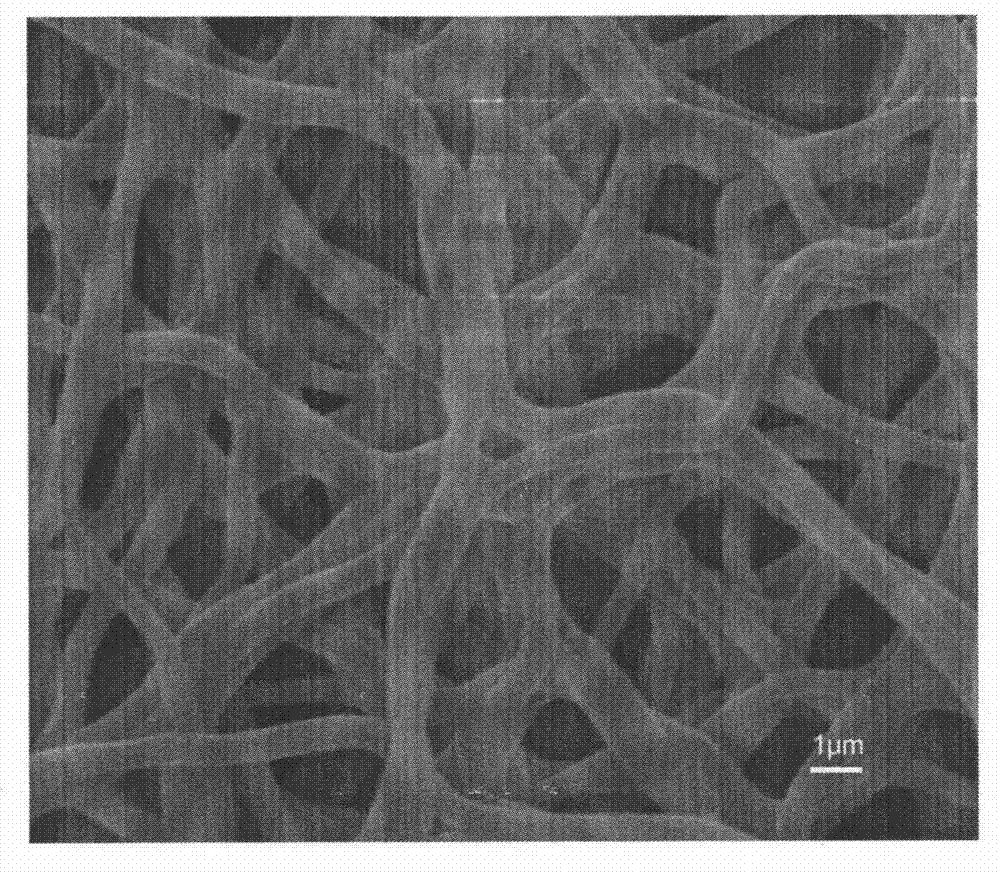

[0029] 2. Dissolving polysuccinimide in dimethylformamide, the mass fraction of the solution is 33%. After stirring completely to dissolve, stand still for degassing, and perform spinning. Set ...

Embodiment 3

[0033] 1. Polysuccinimide is self-made in the laboratory, the raw material is L-aspartic acid, purchased from Aladdin, the purity is 99%, and the specification is A108860-500g. The synthesis method of polysuccinimide is as follows: put finely ground L-aspartic acid and 259g of 85% phosphoric acid in a 2L flask and mix evenly, and react under reduced pressure on a rotary evaporator at 180°C for 2.5h to remove the original water and the water produced by the reaction. After cooling down slightly, 200 mL of DMF was added to dissolve the massive solid formed, and the solution was poured into a beaker containing 1 L of distilled water. Filter and wash the precipitate with water until neutral. Vacuum-dried at 110°C for 24 hours to obtain polysuccinimide with a molecular weight of 30,000.

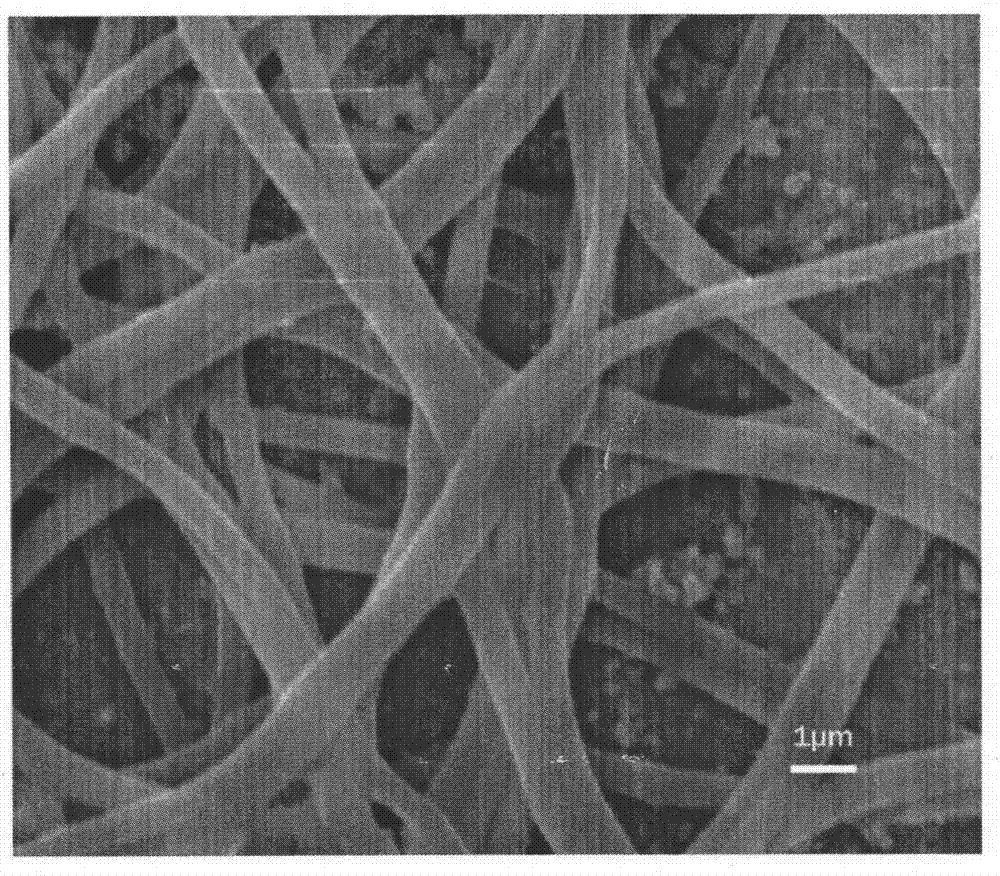

[0034] 2. Dissolving polysuccinimide in dimethylformamide, the mass fraction of the solution is 27%. After stirring completely to dissolve, stand still for degassing, and perform spinning. Set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com